Gravity-loaded high-pressure double-roll squeeze mill

A technology of gravity loading and roller extrusion, applied in grain processing and other directions, can solve the problems of strong horizontal vibration and torsional vibration of the main shaft, premature damage, large impact load, etc., to avoid horizontal vibration and torsional vibration, and improve work reliability. , the effect of increasing the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be described below in conjunction with specific embodiments.

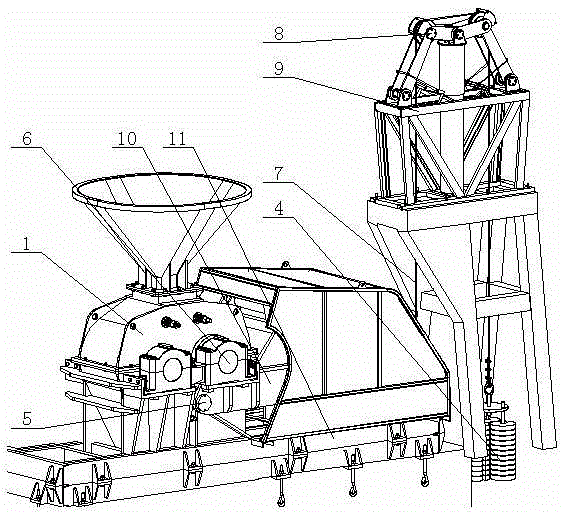

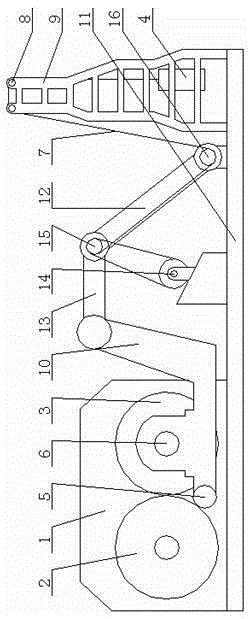

[0022] like figure 1 and figure 2 Shown is a schematic structural view of the gravity-loaded high-pressure double-roll extrusion mill described in the present invention. The gravity-loaded high-pressure double-roll extrusion mill of the present invention includes: a main frame 1 provided with a grinding working chamber; a fixed-axis rotating roller pressing wheel 2 and a movable shaft rotating roller arranged in the pressing-grinding working chamber Pressing wheel 3; a pressing device that is movable on the main frame 1, and the pressing device controls the position of the movable shaft rotating roller pressing wheel 3 so that the fixed axis rotating roller pressing wheel 2 and the movable pressing wheel The shaft rotating roller 3 has an extrusion force; it is characterized in that it also includes a gravity loading mechanism acting on the pressing device, the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com