Flotation method for gold ore with higher mining obturator content

A filling body and gold ore technology, applied in flotation, solid separation, etc., can solve the problems of deteriorating flotation environment, foam stickiness, etc., and achieve the effect of improving flotation efficiency, improving concentrate grade, and improving flotation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

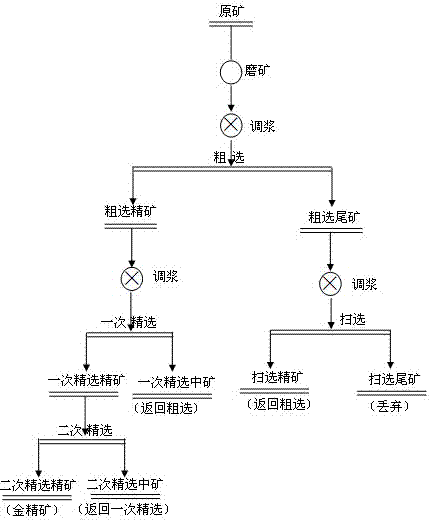

Method used

Image

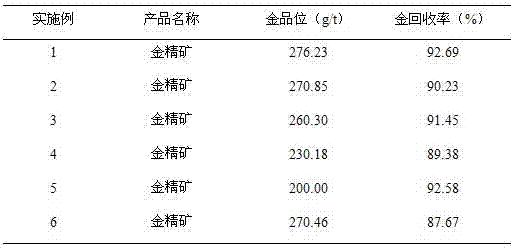

Examples

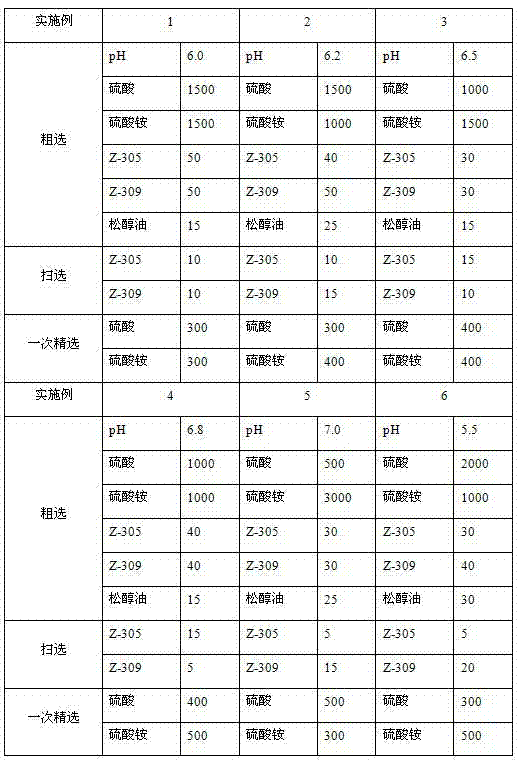

Embodiment 1

[0023] (1) Rough separation: Grinding the raw ore until the ore particles smaller than 0.074mm account for 65%, adding a slurry pH regulator and mining filling inhibitor during grinding, adding water to adjust the slurry to a concentration of 36% , the pH value of the pulp is 6.0, sequentially add collectors and foaming agents, adjust the slurry and stir, and carry out roughing flotation operations to obtain roughing concentrates and roughing tailings;

[0024] (2) Sweeping: Calculated per ton of raw ore, add collectors Z-305 and Z-309 to the roughing tailings in turn, mix the slurry and stir, and carry out scavenging and flotation operations to obtain scavenging concentrate and scavenging Tailings, the scavenging tailings are the final tailings, and the scavenging concentrate returns to the roughing flotation operation to form a closed loop;

[0025] (3) One-time beneficiation: Calculated per ton of raw ore, add pulp pH regulator and mining filling inhibitor to the rough conc...

Embodiment 2

[0029] (1) Rough separation: Grind the raw ore until the ore particles smaller than 0.074mm account for 60%. When grinding, add a slurry pH regulator and a mining filling inhibitor, and add water to adjust the slurry to a concentration of 30%. , the pH value of the slurry is 6.2, sequentially add collectors and foaming agents, adjust the slurry and stir, and carry out roughing flotation operations to obtain roughing concentrates and roughing tailings;

[0030] (2) Sweeping: Calculated per ton of raw ore, add collectors Z-305 and Z-309 to the roughing tailings in turn, mix the slurry and stir, and carry out scavenging and flotation operations to obtain scavenging concentrate and scavenging Tailings, the scavenging tailings are the final tailings, and the scavenging concentrate returns to the roughing flotation operation to form a closed loop;

[0031] (3) One-time beneficiation: Calculated per ton of raw ore, add slurry pH adjuster and mining filling inhibitor in turn to the ro...

Embodiment 3

[0035] (1) Rough separation: Grinding the raw ore until the ore particles smaller than 0.074mm account for 70%, adding a slurry pH regulator and mining filling inhibitor during grinding, adding water to adjust the slurry to a concentration of 40% , the pH value of the slurry is 6.5, adding collectors and foaming agents in sequence, mixing and stirring the slurry, and performing roughing flotation operations to obtain roughing concentrates and roughing tailings;

[0036] (2) Sweeping: Calculated per ton of raw ore, add collectors Z-305 and Z-309 to the roughing tailings in turn, mix the slurry and stir, and carry out scavenging and flotation operations to obtain scavenging concentrate and scavenging Tailings, the scavenging tailings are the final tailings, and the scavenging concentrate returns to the roughing flotation operation to form a closed loop;

[0037] (3) One-time beneficiation: Calculated per ton of raw ore, add slurry pH adjuster and mining filling inhibitor in turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com