A feeding mechanism for making water meter copper joints

A technology of feeding mechanism and copper joint, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of difficult realization of material selection area and discharge area, affecting the operation of feeding mechanism, and large error of manual sorting, etc., to achieve The structure has a high degree of automation, avoiding the confusion of workpiece transmission and achieving the effect of orderly transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

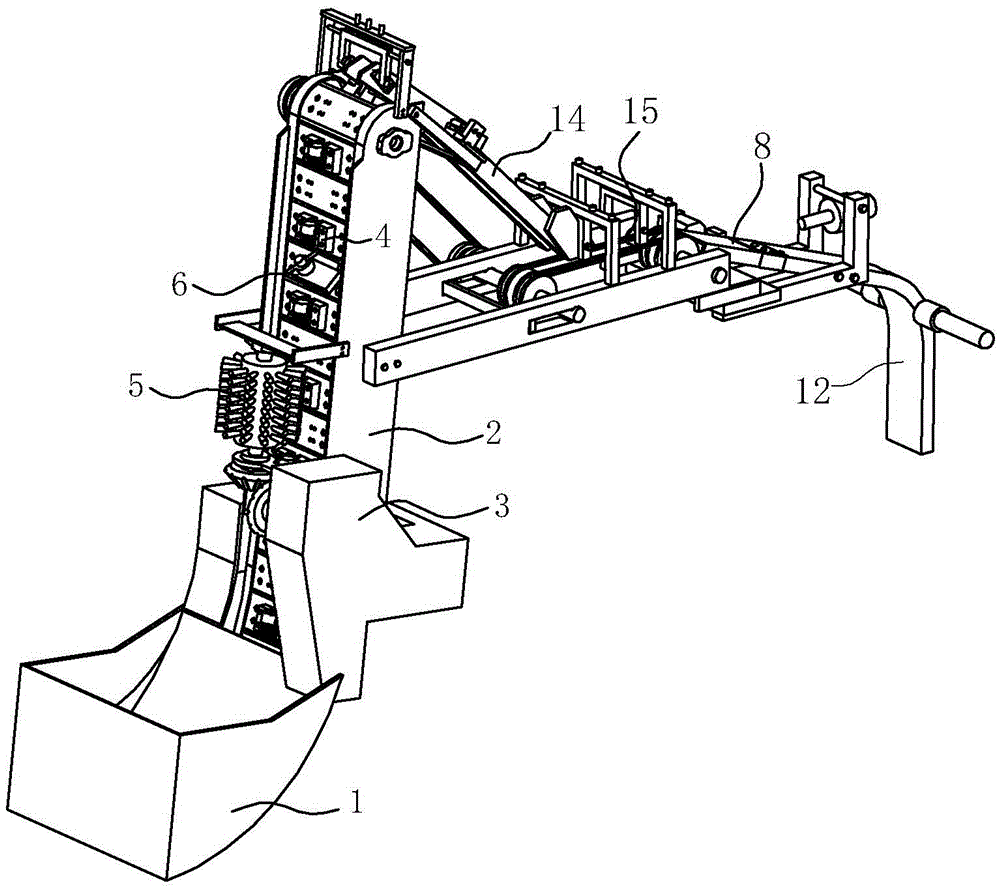

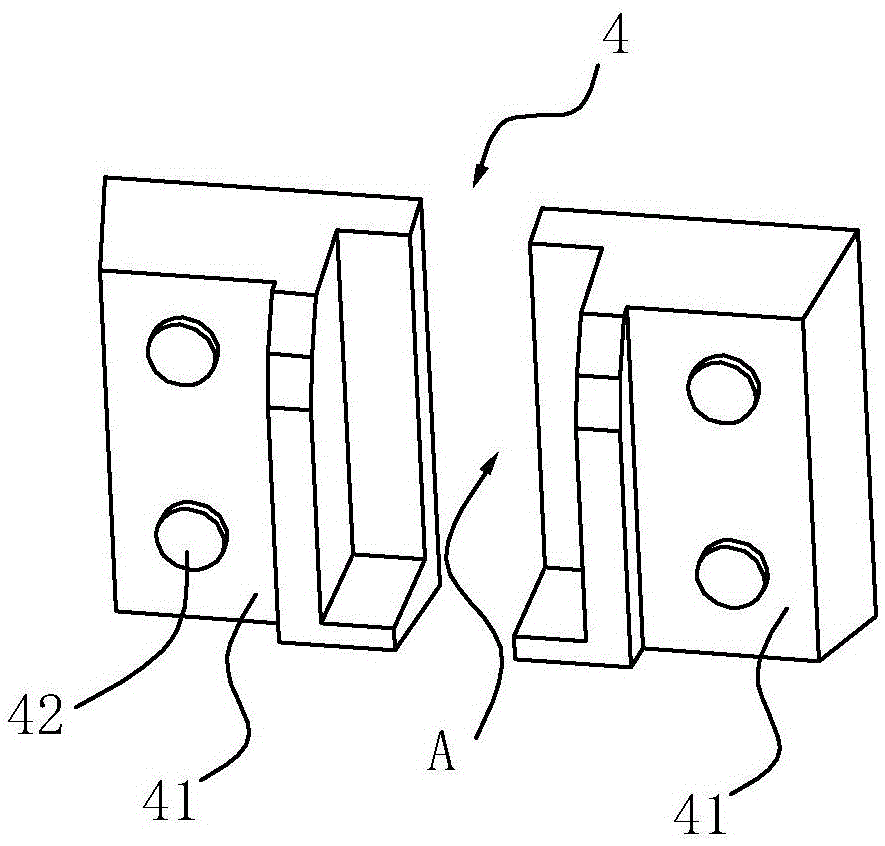

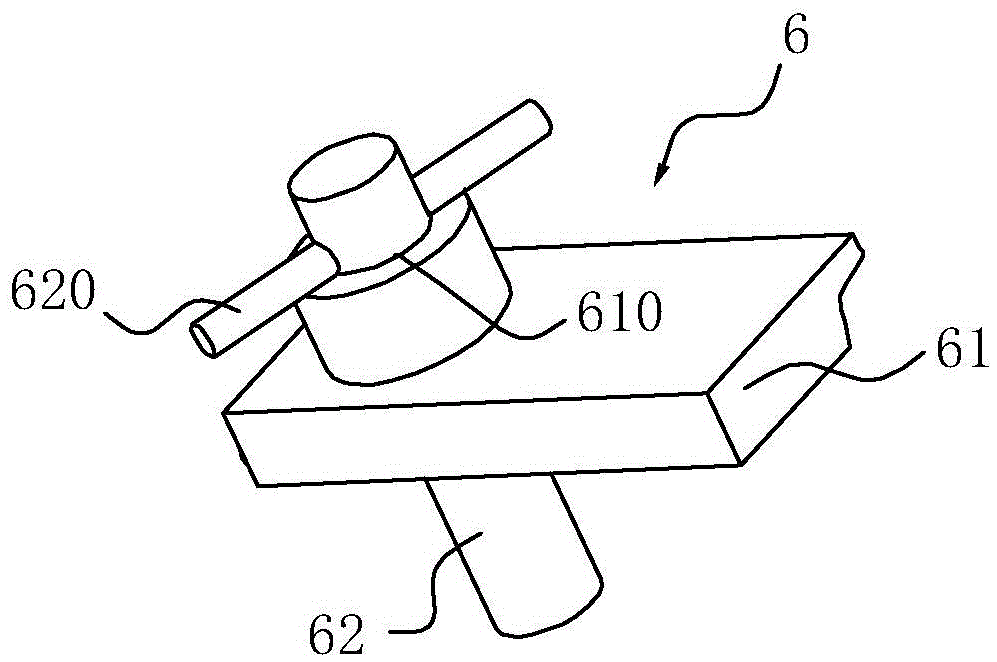

[0027]The feeding mechanism for making water meter copper joints in this embodiment mainly includes a climbing device with a storage box, a transmission mechanism, a material selection device and a sorting device, and the climbing device, the transmission mechanism, the material selection device and the sorting device are connected in sequence . The semi-finished water meter copper joints in the storage box are conveyed in an orderly manner through the climbing device, and then enter the material selection device for sorting through the transmission mechanism. The joint semi-finished products are introduced into the sorting device and wait to be transported to the external processing machine tool to complete the final processing.

[0028] Such as figure 1 As shown, the climbing device of the feeding mechanism includes a storage box 1 for sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com