Device for conducting electrical discharge machining on outer surface with complex shape

An electrical discharge machining, external surface technology, applied in electric machining equipment, metal machining equipment, electrode manufacturing, etc., can solve problems such as difficulty in meeting actual production needs, forming electrode production, installation difficulty, tool electrode wear, etc., to promote industrial The application and technical means are simple and easy to implement, and the effect of fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

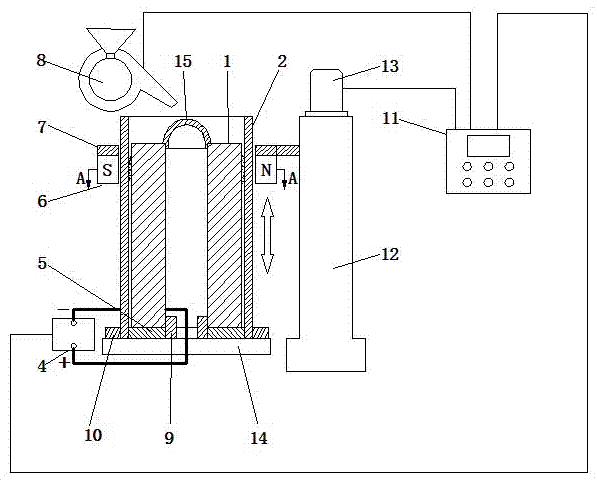

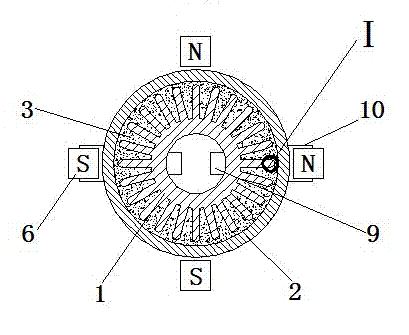

[0030] Such as figure 1 and image 3 As shown, a device for performing electrical discharge machining on a complex-shaped outer surface includes a processing power source 4, a workpiece fixture 9 for clamping a workpiece 1, and also includes:

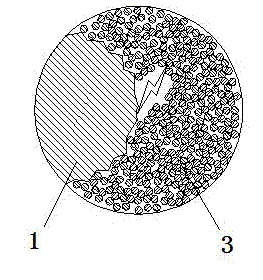

[0031] The outer edge electrode 2 is fixed on the workbench 14 through the electrode fixture 10, and surrounds the outer surface of the workpiece 1 to be processed, and the inner wall of the outer edge electrode 2 is separated from the outer edge of the workpiece 1 by a certain gap

[0032] Feed system 12, one end of the feed system 12 is provided with a motor 13, and the side wall is provided with a magnetic pole clamp 7 that can reciprocate linearly within a predetermined stroke range under the drive of the motor 13;

[0033] The ring-shaped magnetic pole group 6 is fixedly arranged on the magnetic pole holder 7, surrounds the outer wall of the outer edge electrode 2 with a certain gap, and can perform linear reciprocating motion alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com