Workpiece pressing device and drill press workbench with same

A technology of pressing device and worktable, applied in positioning devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of reduced versatility of pressing devices, deformation of moving guide rails, inability to meet customers, etc., and achieves easy loading of workpieces, The effect of stable and flexible movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

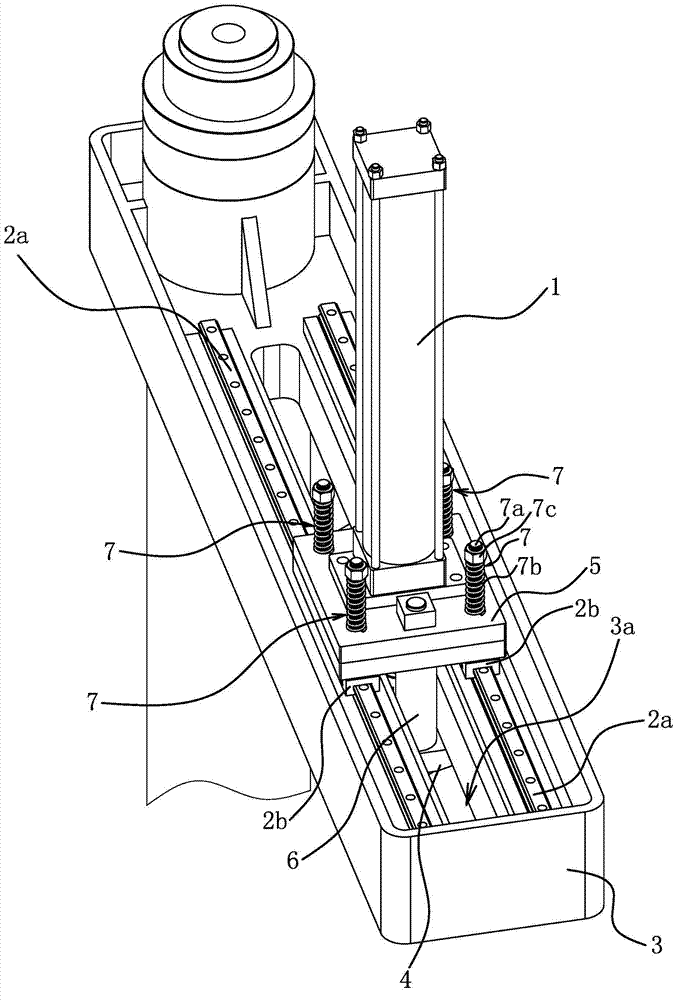

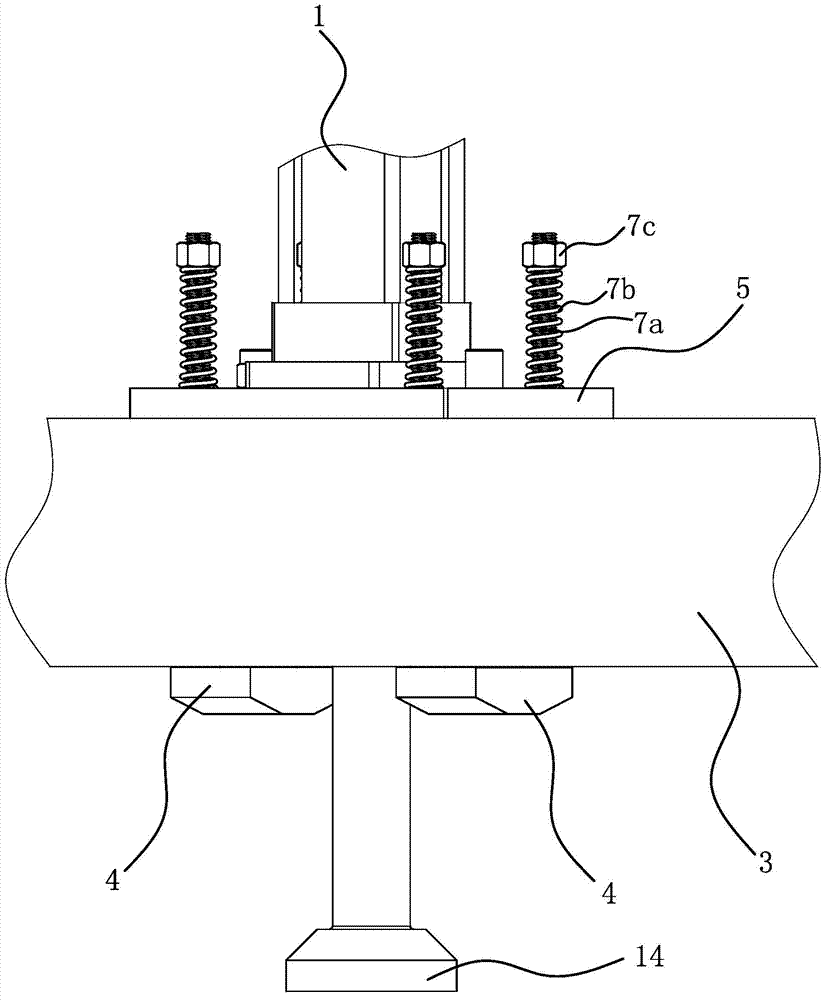

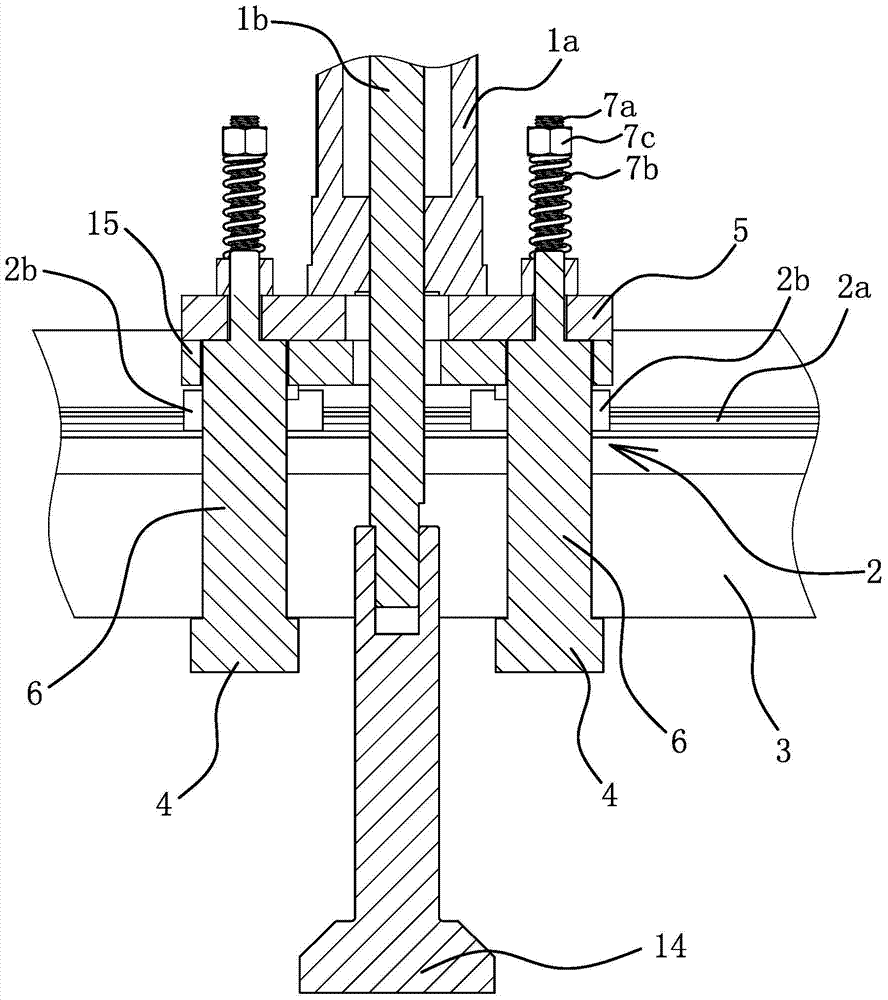

[0029] Such as figure 1 with figure 2 As shown, the workpiece pressing device includes an oil cylinder 1, a guide rail 2a assembly 2, a pressing arm 3, a pressure receiving block 4 and a connecting plate 5.

[0030] Cylinder 1 is a pressure source that applies pressure to the workpiece. Adopting the oil cylinder 1 as the pressure source has the advantages of stable feed, high pressure that can be applied to the workpiece and long-term pressure stability.

[0031] The pressing arm 3 is a basic component for other components to be installed, and is also a force bearing component.

[0032] The guide rail 2 a of the guide rail assembly 2 is fixedly connected with the pressing arm 3 ; all the sliders 2 b of the guide rail assembly 2 are connected with the connecting plate 5 . The cylinder body 1a of the oil cylinder 1 is fixedly connected with the connecting plate 5; the pressure receiving block 4 and the connecting plate 5 are located on both sides of the pressing arm 3 respec...

Embodiment 2

[0046] The structure and principle of this embodiment are basically the same as those of the first embodiment, except that the pressing arm 3 and the base 8 are connected by a fixed connection structure. The fixed connection structure includes a column 10 , the base 8 has a column connecting seat 11 , the pressing arm 3 is fixedly connected to the upper end of the column 10 , and the lower end of the column 10 is fixedly connected to the column connecting seat 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com