Rock sample cutting device capable of producing different joint angle and different joint connectivity rates

A technology of cutting equipment and connectivity rate, which is applied in the field of rock test piece equipment and rock sample cutting machine, can solve the difficulty of accurately batch-making single-joint bedding rock mass test pieces, it is difficult to make non-penetrating joint rock samples, and there is no consideration To achieve the effect of multi-dimensional control, convenient and reliable operation, and simple instrument manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

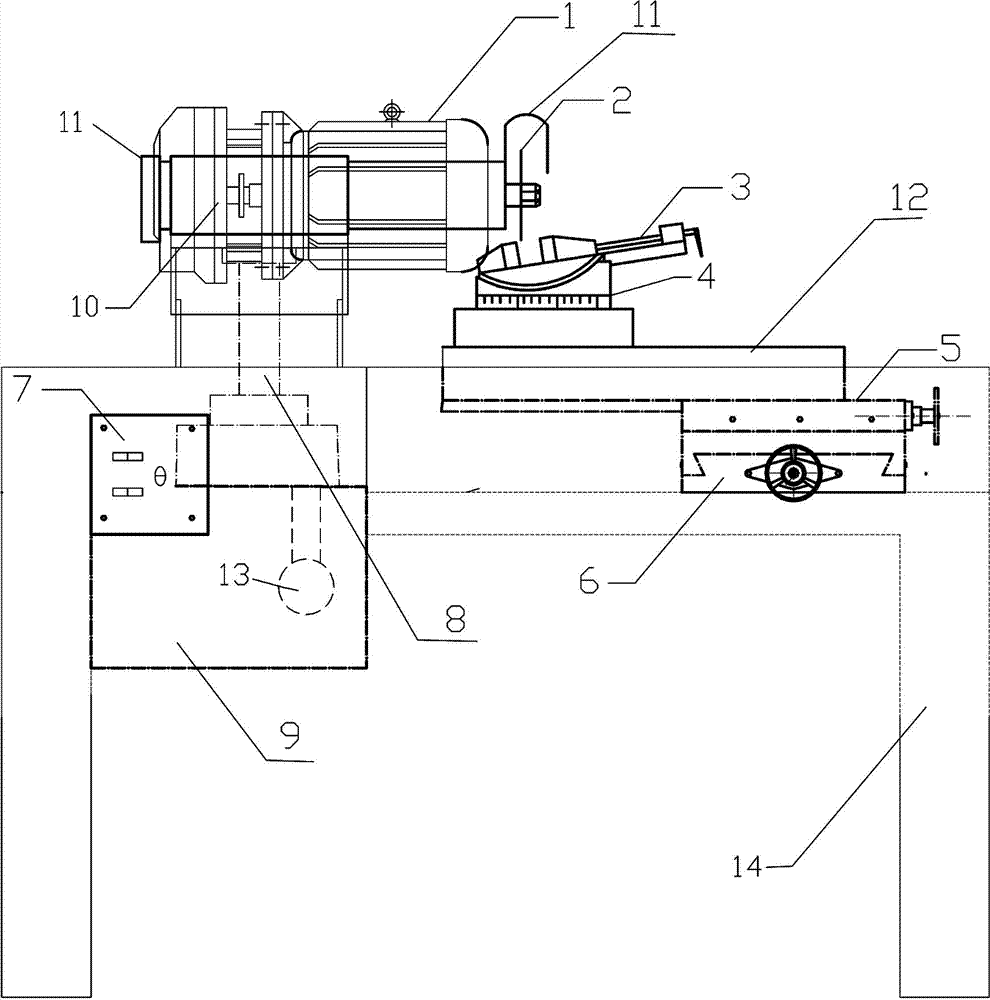

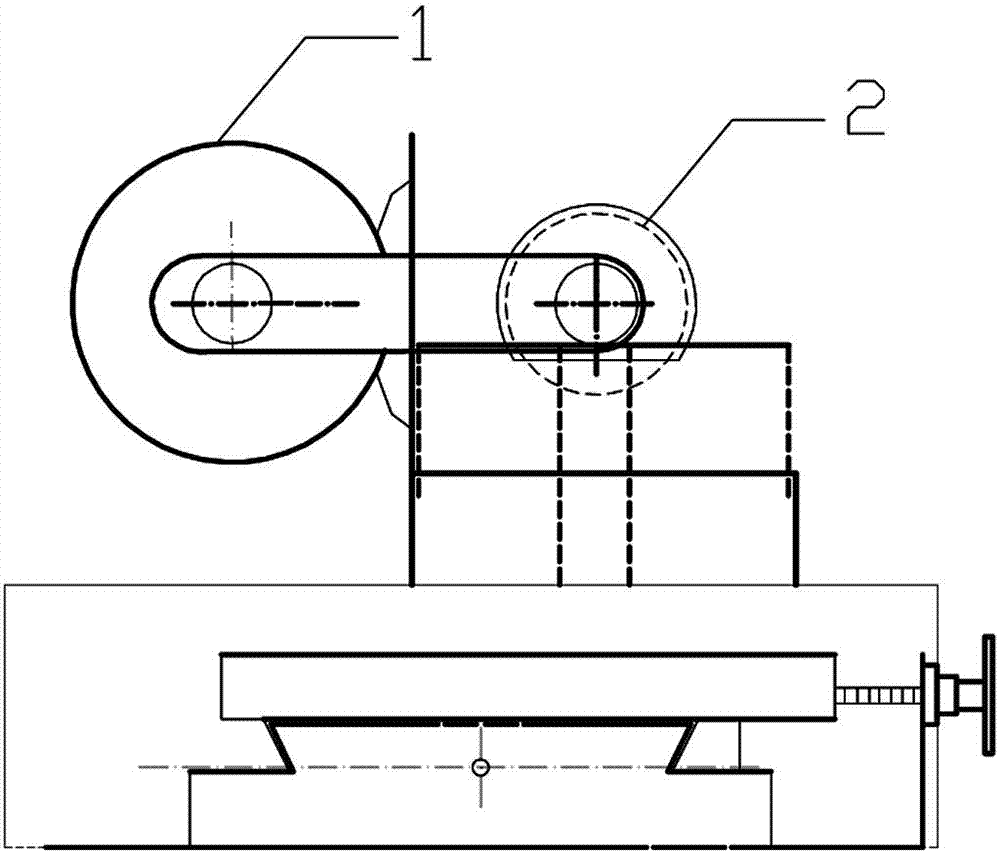

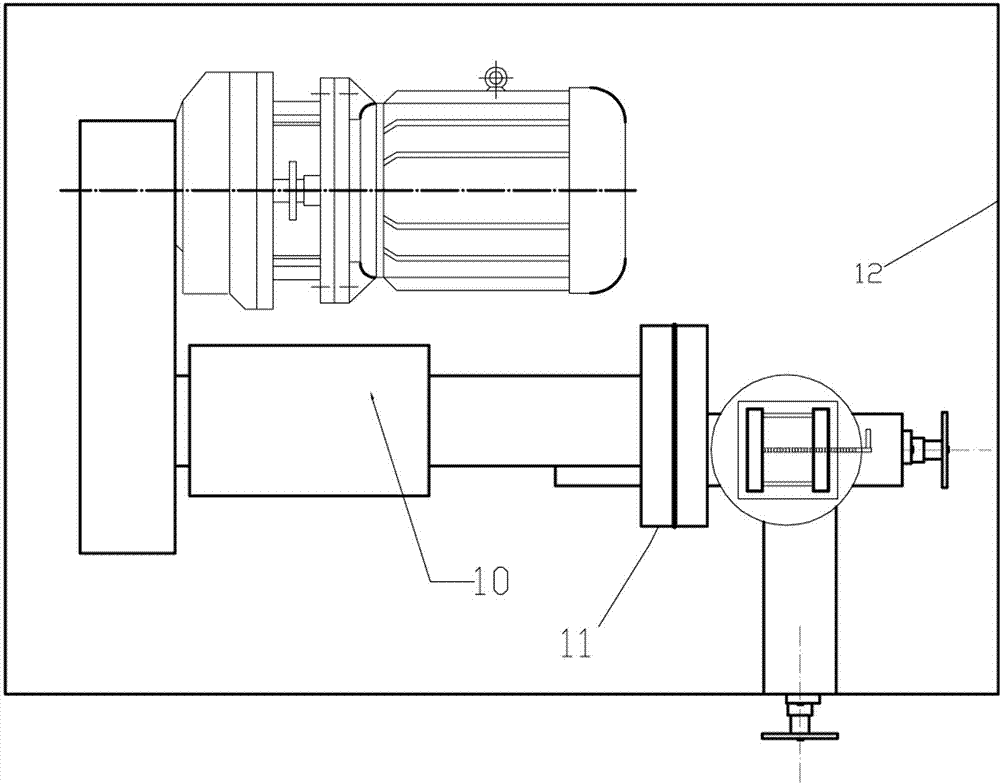

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] see Figure 1-3 , a rock sample cutting device that can produce different joint angles and different joint connectivity rates, it includes a stainless steel bracket 14, the upper end of the stainless steel bracket is provided with a cutting machine through a jack 8, the cutting machine is driven by a motor 1, and the main shaft of the cutting machine 10 is provided with a cutting blade 2, the lower part of the cutting blade is located on the plane of the stainless steel bracket and is provided with a working plate 12, the upper part of the working plate is provided with a two-way rotating vise 3, and the lower part of the working plate is provided with a longitudinal dovetail plate 5 and a horizontal dovetail plate 6 , the longitudinal dovetail plate and the transverse dovetail plate are used to control the longitudinal and lateral movement of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com