Production process for recycling premixed concrete solid waste residues

A technology of ready-mixed concrete and solid waste, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc. It can solve the problems of difficult separation, high energy consumption, and difficult pulverization process, so as to reduce the difficulty, The effect of increasing throughput and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

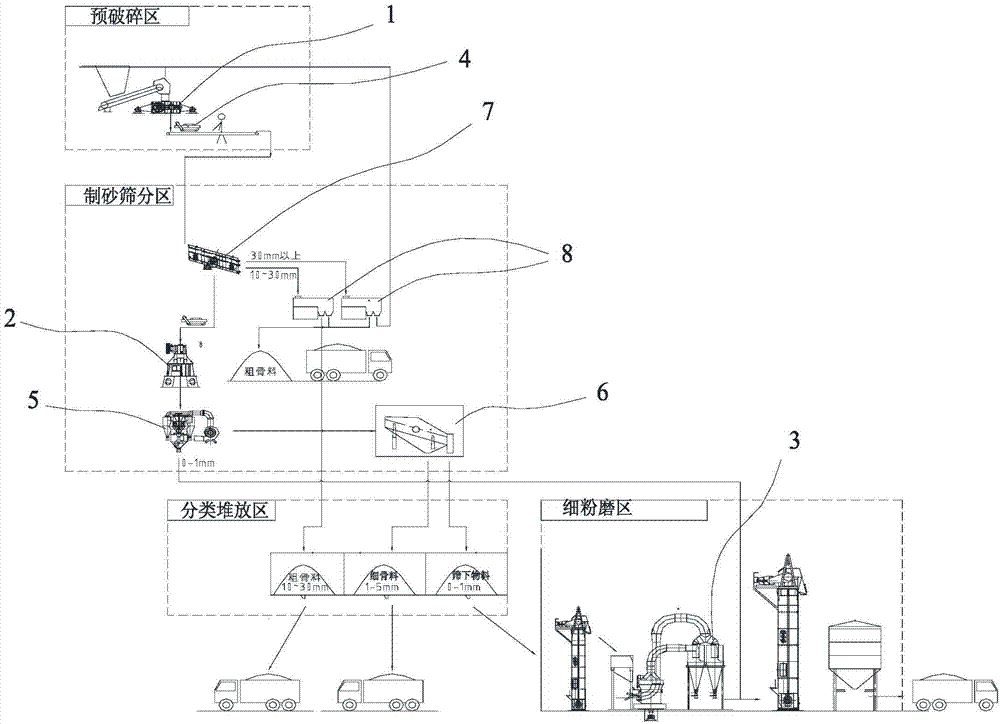

Image

Examples

Embodiment 1

[0041]1) Collect concrete waste in the concrete batching plant;

[0042] 2) The concrete waste slag is broken into blocks with a particle size of less than 30 mm by using a medium-pressure toothed roller press 1;

[0043] 3) Use a vibrating sieve to separate the coarse aggregate with a particle size greater than 10 mm from the product obtained in step 2); the coarse aggregate index meets the technical requirements of recycled coarse aggregate for concrete (GB / T 25177).

Embodiment 2

[0045] 1) Collect concrete waste in the concrete batching plant;

[0046] 2) The concrete waste slag is broken into blocks with a particle size of less than 30 mm by using a medium-pressure toothed roller press 1;

[0047] 3) Using a vibrating screen to separate the product obtained in step 2) into coarse aggregate and under-screen material;

[0048] 4) Using a conical cavity mill to crush the under-screen material obtained in step 3) to a particle size smaller than 5 mm;

[0049] 5) Use a vibrating screen to separate the product obtained in step 4) into fine aggregate and under-screen material. The particle size of the fine aggregate is greater than 1 mm, and the index meets the technical requirements of recycled fine aggregate for concrete and mortar (GB / T 25176) .

Embodiment 3

[0051] 1) Collect concrete waste in the concrete batching plant;

[0052] 2) The concrete waste slag is broken into blocks with a particle size of less than 30 mm by using a medium-pressure toothed roller press 1;

[0053] 3) Using a vibrating screen to separate the product obtained in step 2) into coarse aggregate and under-screen material;

[0054] 4) Using a conical cavity mill to crush the under-screen material obtained in step 3) to a particle size smaller than 5 mm;

[0055] 5) Use a vibrating screen to separate the product obtained in step 4) into fine aggregate and under-size material, and the under-size material will continue to be fed into the high-efficiency pulverizer to produce active ultra-fine powder products with a particle size of less than 0.025 mm, which can be used as concrete grinding Admixtures are used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com