A kind of renaturation method of insulin glargine precursor

A technology of insulin glargine and its precursor, which is applied in the field of renaturation of insulin glargine precursor, can solve the problems of low recovery rate, achieve the effects of fewer by-products, lower production costs, and shorter reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Refolding of embodiment 1 insulin glargine precursor

[0057] At room temperature, dissolve 10 grams of insulin glargine precursor in 588 mL of 6M, pH9.5 urea solution to make the protein concentration of insulin glargine precursor about 17 g / L; then add 5 g of DTT to adjust the pH value to 9.5, control The temperature of the reaction system was 35° C., and the reaction was carried out for 30 minutes.

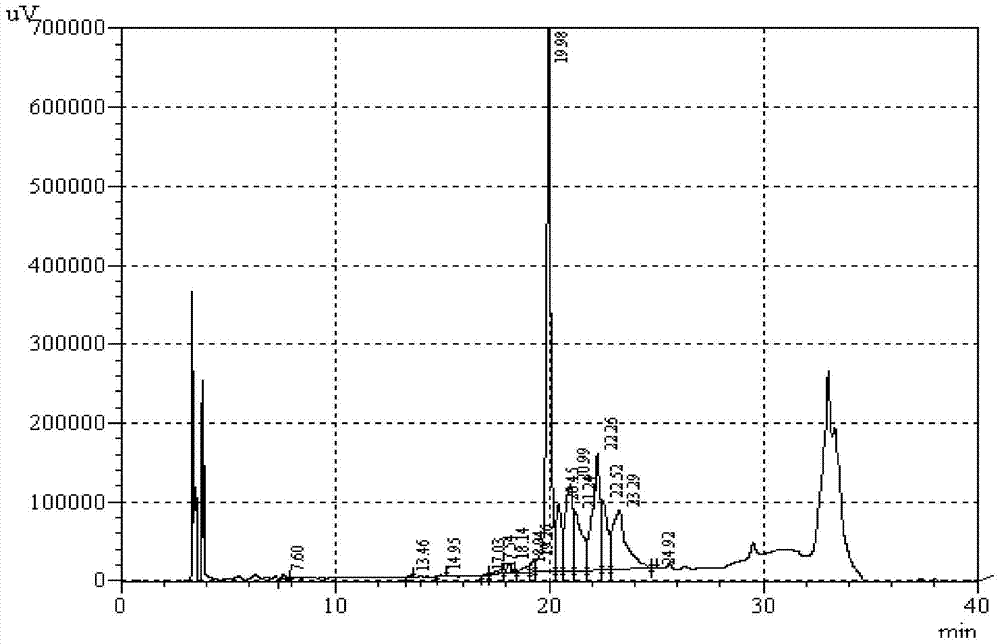

[0058] Add the denatured insulin glargine precursor solution to 10 mM, pH9.5 Tris-HCl buffer solution, and use the Tris-HCl buffer solution to set the volume to 10 L, so that the protein concentration of the insulin glargine precursor is 1.0 g / L, Then add 5g PEG4000, 500mL glycerol, 8mg CuSO 4 , adjust the pH value to 9.5, with 20cm 3 Air was continuously fed into the refolding solution at a rate of / H, the temperature of the reaction system was controlled at 4°C, and the reaction was stopped after 12 hours of reaction. Take 20 μL of the refolding solution and analyze...

Embodiment 2

[0059] Refolding of embodiment 2 insulin glargine precursor

[0060] At room temperature, dissolve 10 grams of insulin glargine precursor in 357 mL of 8M, pH 11.5 urea solution, so that the protein concentration of insulin glargine precursor is about 28 g / L, add 2.5 g of DTT, adjust the pH value to 11.5, control The temperature of the reaction system was 45° C., and the reaction was carried out for 60 minutes.

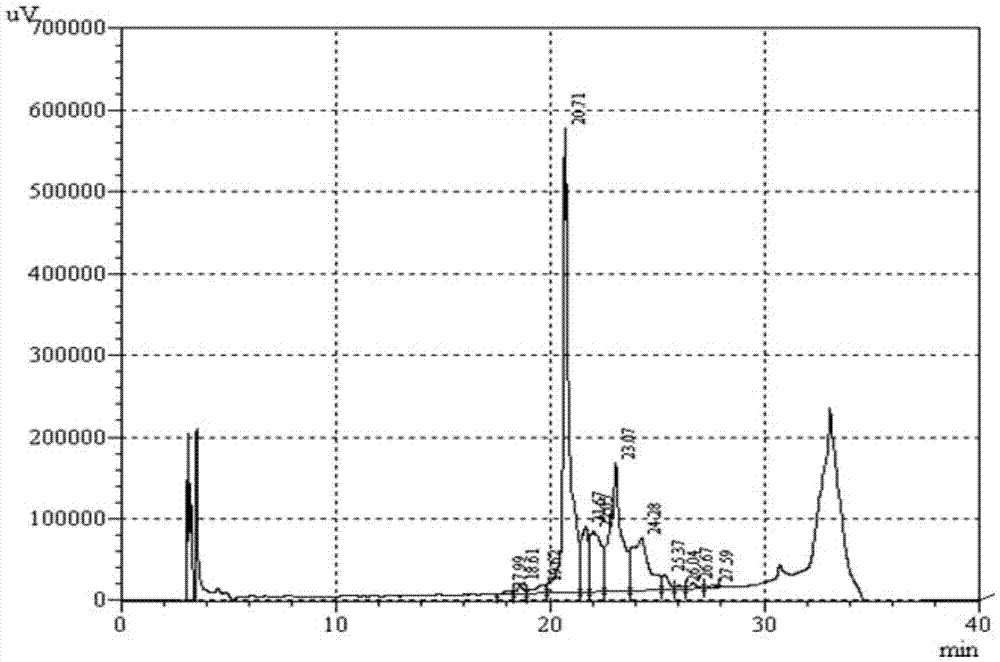

[0061] Add the denatured insulin glargine precursor solution to 50mM, pH11.5 Tris-HCl buffer solution, and use the Tris-HCl buffer solution to set the volume to 7.14L, so that the protein concentration of the insulin glargine precursor is 1.4g / L , followed by adding 14.28g PEG4000, 1428mL glycerol, 22.85mg CuSO 4 , adjust the pH value to 11.5, to 714cm 3 Air was continuously fed into the refolding solution at a rate of / H, the temperature of the reaction system was controlled at 15°C, and the reaction was stopped after 25 hours of reaction. Take 20 μL of the refoldi...

Embodiment 3

[0062] Refolding of embodiment 3 insulin glargine precursor

[0063] At room temperature, dissolve 10 grams of insulin glargine precursor in 588 mL of 6M, pH 9.5 urea solution to make the protein concentration of insulin glargine precursor about 17 g / L, add 5 g of cysteine hydrochloride to adjust the pH The value is 9.5, the temperature of the reaction system is controlled at 35° C., and the reaction is carried out for 30 minutes.

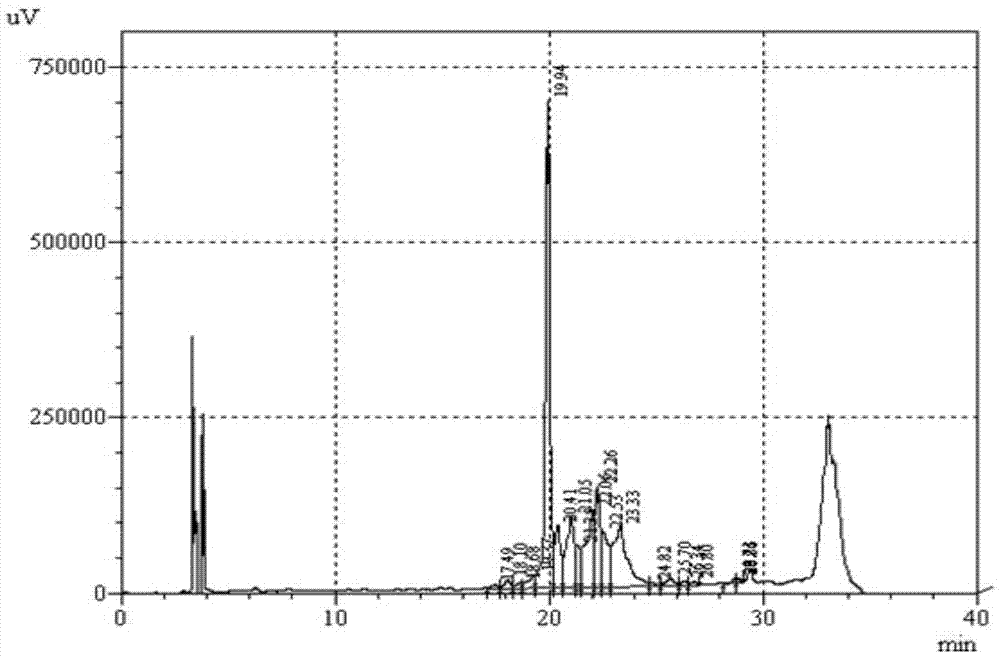

[0064] Add the denatured insulin glargine precursor solution to 10mM, pH9.5 glycine dilution buffer, and dilute to 10L with the glycine dilution buffer to make the protein concentration of the insulin glargine precursor 1.0g / L, then add 5g PEG4000, 500mL glycerol, 6.75mg CuCl 2 , adjust the pH value to 9.5, with 20cm 3 Air was continuously fed into the refolding solution at a rate of / H, and the temperature of the reaction system was controlled at 4 ° C. After 12 hours of reaction, the reaction was stopped. Take 20 μL of the refolding solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com