Polyamide acid combination, polyimide combination, laminated body, circuit board, usage thereof, laminated body and manufacturing method of the laminated body

A technology of polyamic acid and polyimide, which is applied in the direction of circuit substrate materials, printed circuits, and other household appliances, can solve the problems of easy peeling of the wiring layer and the decrease of the adhesion between the resin substrate and the wiring layer, and achieve The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

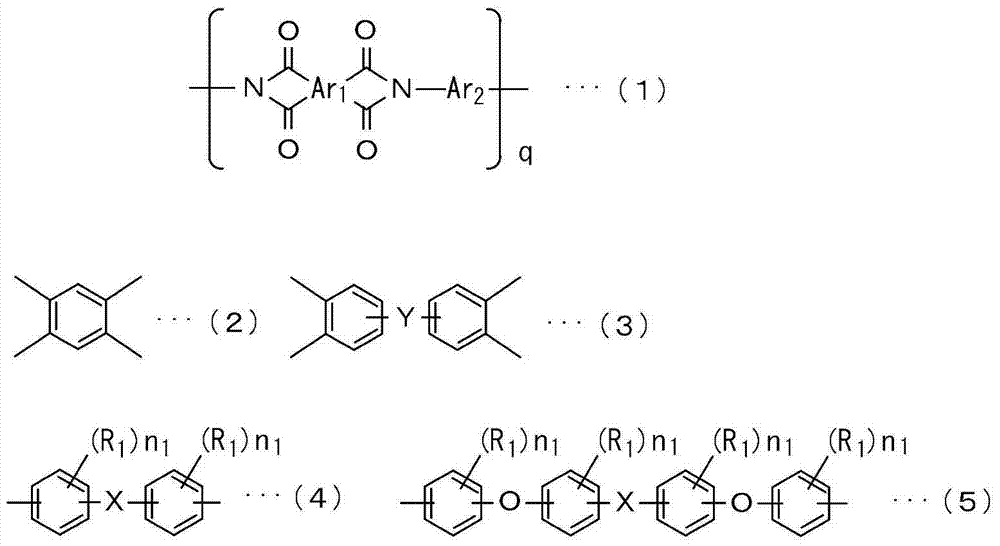

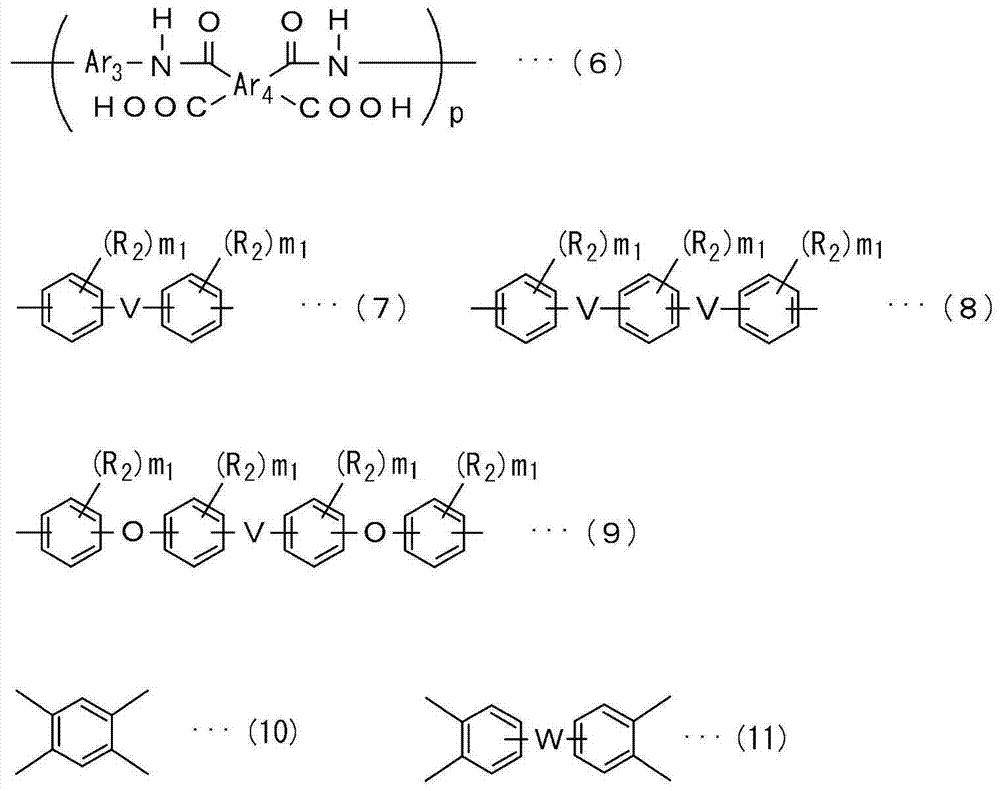

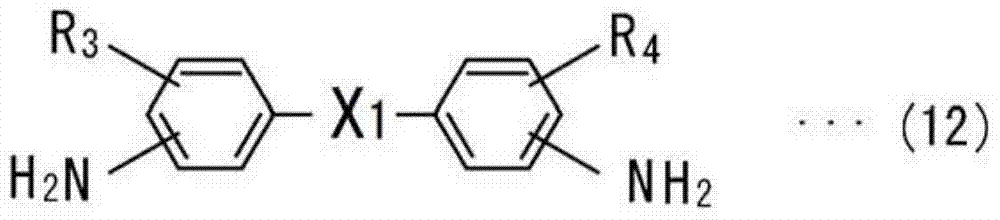

Method used

Image

Examples

preparation example Construction

[0075]

[0076] The polyamic-acid composition inject|throws in the said preparation ratio the polyamic acid of the said (A) component, and the acrylic compound of (B) component, and mixes it and prepares it. When preparing a polyamic acid composition, it is preferable to use a solvent as needed.

[0077] [Polyimide composition]

[0078] The polyimide composition of this embodiment heat-processes a polyamic-acid composition, and is obtained by imidating the polyamic acid of (A) component. The imidization method is not particularly limited, for example, heat treatment is suitably used, that is, heating is performed at a temperature in the range of 80° C. to 400° C. within a time range of 1 minute to 60 minutes.

[0079] In the polyimide composition of this embodiment, it is considered that the acrylic compound exists in the polyimide in a non-bonding state. Here, the "non-bonded state" means that the functional group of the acrylic compound does not form a bond with the poly...

no. 1 Embodiment approach

[0094] The first embodiment of the polyimide having the function of trapping sulfur-containing organic compounds can use the following polyimide composition obtained by heat-treating the following polyamic acid composition to imidize it. Obtain, the polyamic acid composition comprises following component (A) and component (B):

[0095] (A) polyamic acid having a weight average molecular weight in the range of 10,000 to 150,000, and

[0096] (B) an acrylic compound, and

[0097] The said (B) component is contained in the range of 0.1 weight part - 60 weight part with respect to 100 weight part of said (A) components. In 1st Embodiment, the said compound can be used for the polyamic acid of (A) component, and the acrylic compound of (B) component.

no. 2 Embodiment approach

[0099] The thermoplastic polyimide of the second embodiment is a thermoplastic polyimide obtained by heat-treating polyamic acid obtained by the reaction of an aromatic diamine and an aromatic tetracarboxylic dianhydride to imidize it. amine. Here, the aromatic diamine contains an aromatic diamine having a radically polymerizable unsaturated bond within a range of 2 to 6 carbon atoms, and the amount of the radically polymerizable unsaturated bond per 1 g of the polyamic acid is 0.096 In the range of mmol~3mmol.

[0100] The metal-clad laminate and the circuit board produced using the thermoplastic polyimide of the second embodiment can maintain the gap between the metal layer and the resin layer even after 1000 hours or more are immersed in oil at 150°C containing a sulfur compound. of high adhesion. As described above, in the second embodiment, the radically polymerizable unsaturated bond in the thermoplastic polyimide functions as a trapping means for trapping sulfur compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of linear thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com