A kind of compound unblocking method

A technology of tubing and rotary injection, which is applied in the direction of earthwork drilling, wellbore/well components, flushing wellbore, etc. It can solve the problems of sand control screen clogging, poor process effect, and failure to discharge large particle blockages. Wide range of plugging and the effect of preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

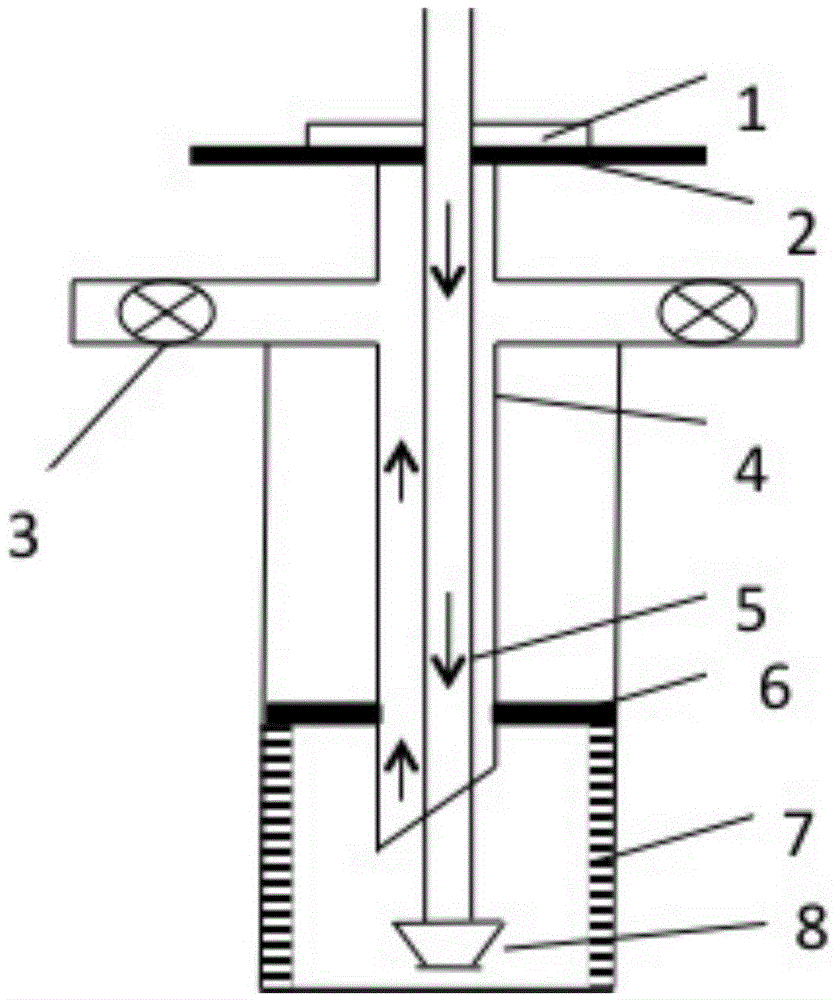

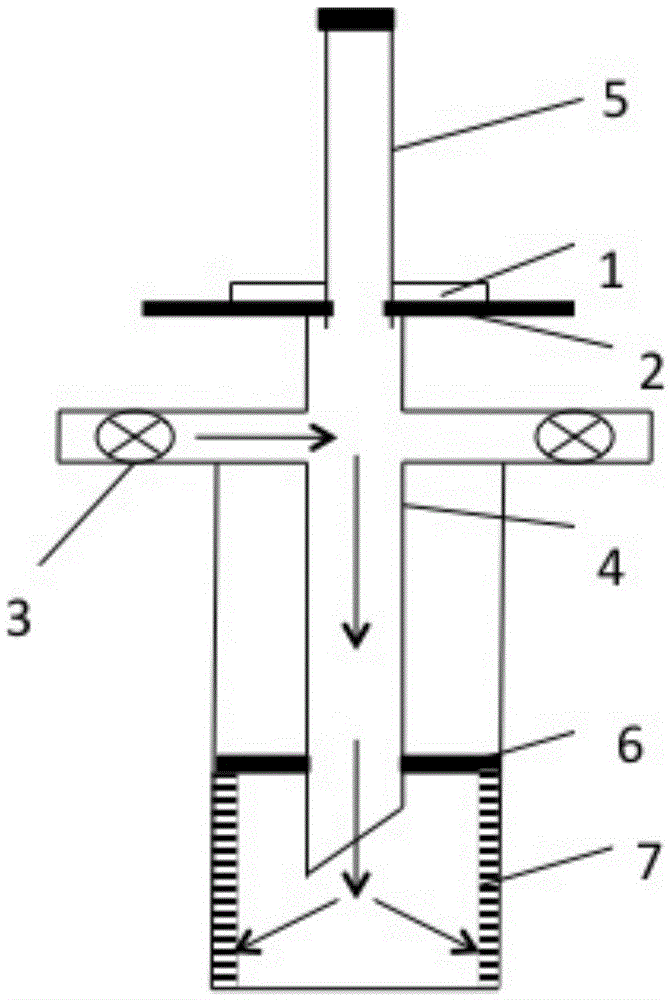

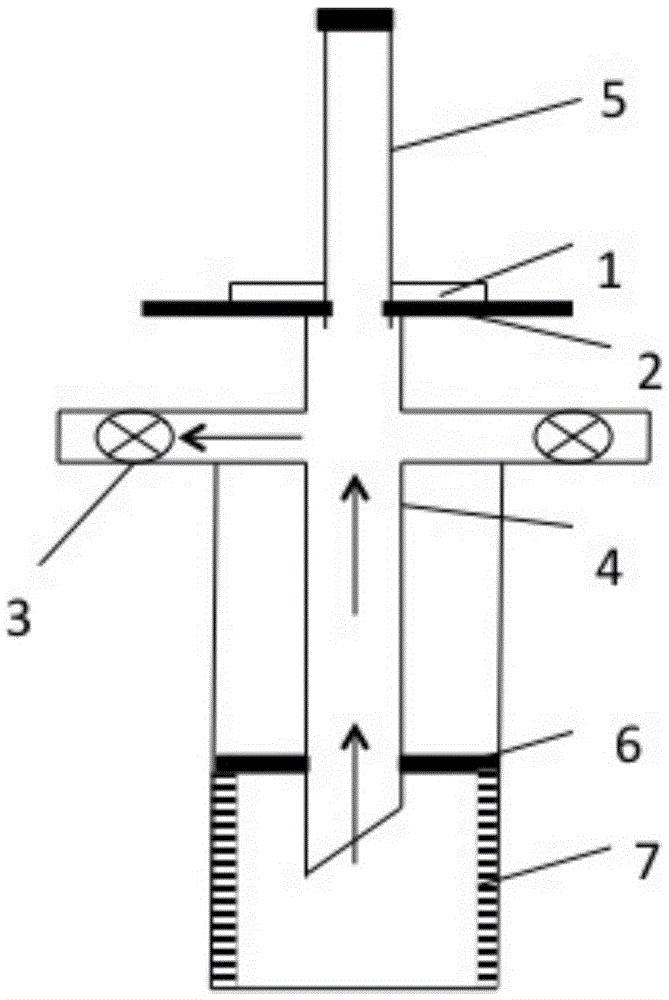

[0028] The invention provides a composite plugging removal method, combining figure 1 , figure 2 , image 3 as well as Figure 4 As shown, it may include rotary jet cleaning operation, oil pipe positive extrusion foam operation, oil pipe blowout operation and negative pressure flowback operation; wherein, the relevant description of the accompanying drawings is as follows: the coiled tubing blowout preventer 1 is arranged on the turntable surface 2, and the oil pipe 4 The channel 3 is connected to the main road of the oil pipe 4, the coiled tubing 5 is arranged inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com