Steel strip reinforced polyethylene helically corrugated tube and production method thereof

A technology of polyethylene spiral and bellows, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of poor bonding, potential safety hazards, easy breakage, etc., achieve stable shape and quality, increase Adhesive strength, the effect of increasing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

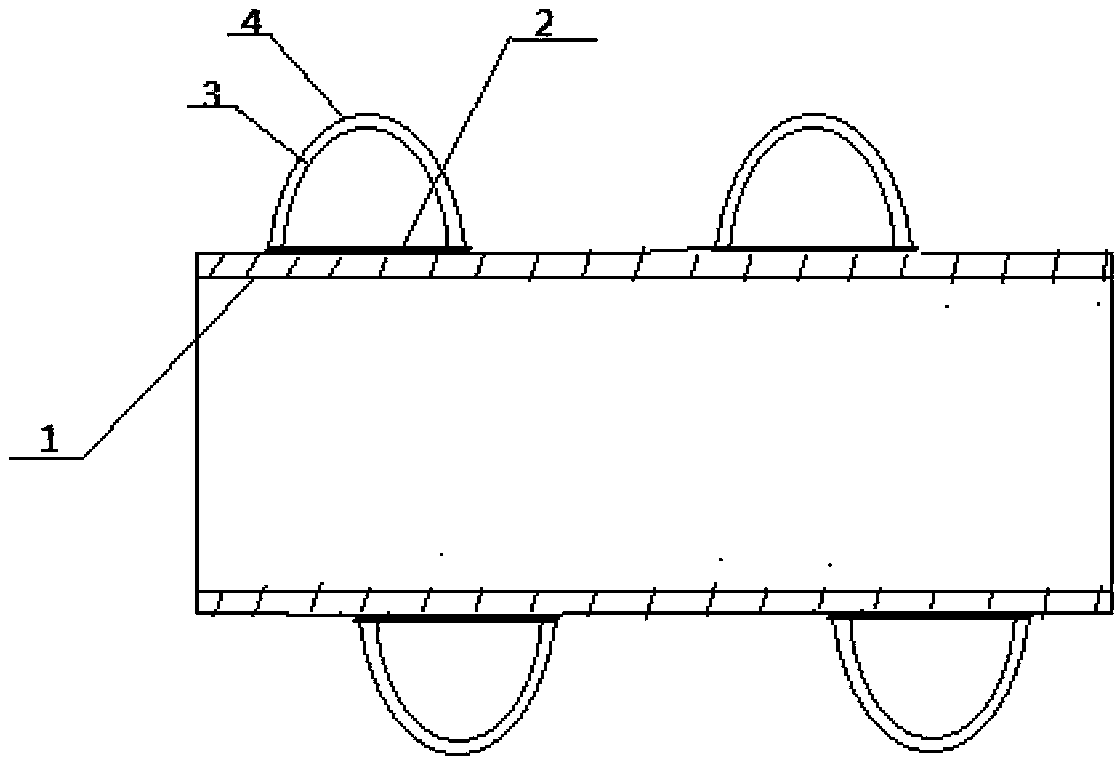

[0015] refer to figure 1 The plastic raw material polyethylene is extruded from the inner layer extruder and welded into the inner tube layer 1, the pretreated steel belt is pressed into a V-shaped steel belt by a bending machine, and the steel mesh 2 is welded on the steel mesh by a welding machine. On the two legs of the V-shaped steel belt 3, and coat the resin on the plane of the steel mesh 2 and the two legs of the V-shaped steel belt 3, and then use a bending machine to bend and wind the coated steel belt with the steel mesh For the outer layer of the pipe 1, use the outer layer extruder to weld the polyethylene tape material to the inner pipe and the outer layer of the V-shaped steel belt to form the outer polyethylene layer 4.

[0016] The embodiments described in the present invention are illustrative, rather than limiting, so the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com