Method for measuring occurrence of non-contact structural surface

A measurement method, non-contact technology, applied in the direction of measuring devices, measuring angles, surveying and navigation, etc., can solve the problems that the geological compass is greatly affected by magnetic interference, it is difficult to ensure that the measured value is consistent with the objective true value, and the operation process of the instrument is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

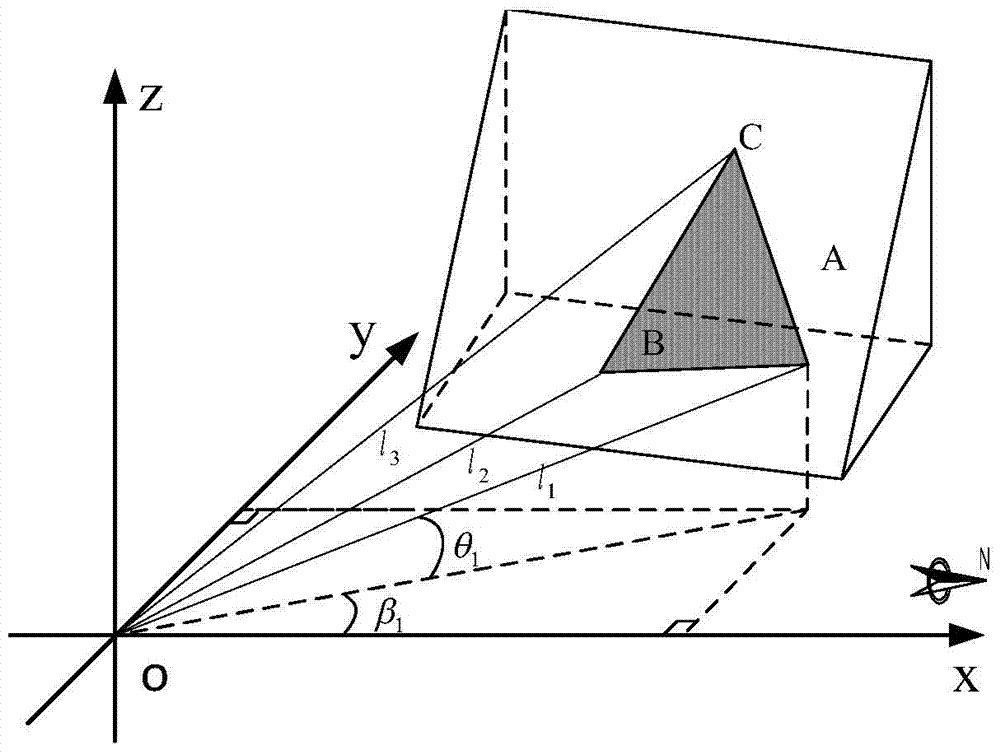

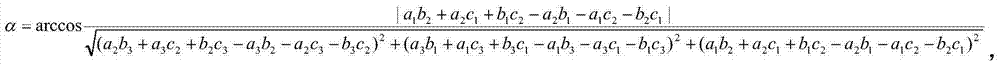

[0035] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and derivation formulas.

[0036] The main effect of the present invention is to use a non-contact method to measure the occurrence of the structural surface, and there are no strict restrictions on the position and angle of the measuring point and the size of the structural surface. The specific operation steps are as follows:

[0037] (1) Place the laser or infrared rangefinder along with the measuring instrument on the station, and the station can be selected arbitrarily without affecting the beam emission and reception.

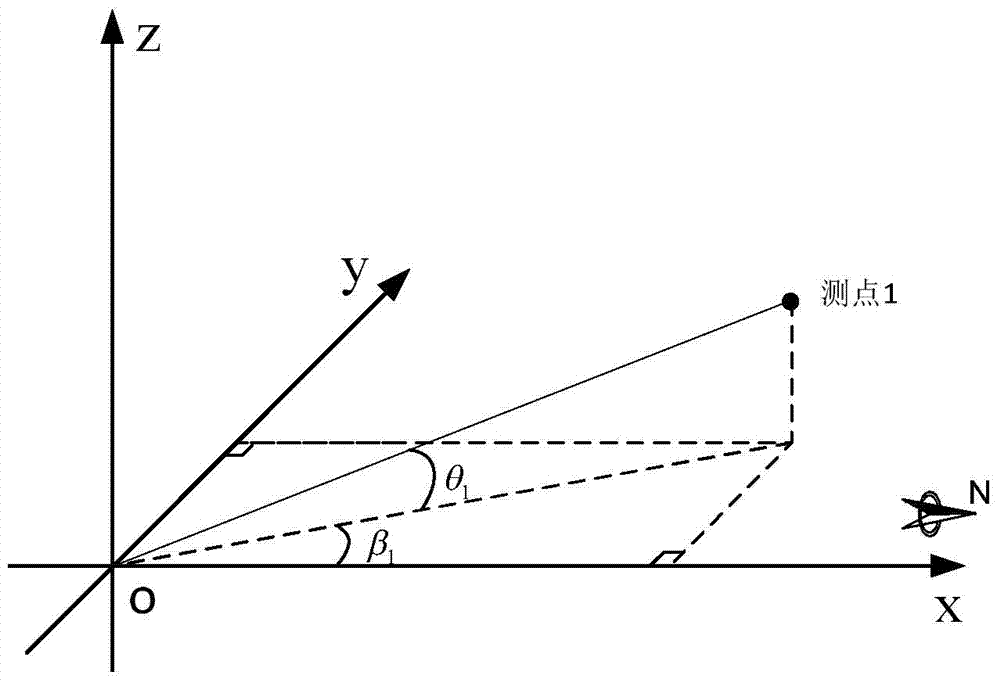

[0038] (2) if figure 1 As shown, take the station of the instrument as the origin of the coordinate system, take the positive direction of the x-axis as the magnetic north direction, and then determine the y-axis and z-axis according to the right-hand rule to establish a spatial Cartesian rectangular coordinate sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com