Liquid crystal panel and liquid crystal display device

A liquid crystal panel and one-sided technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of difficult liquid crystal panel narrow frame design, etc., and achieve the effect of narrow frame design, small frame, and reduced frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

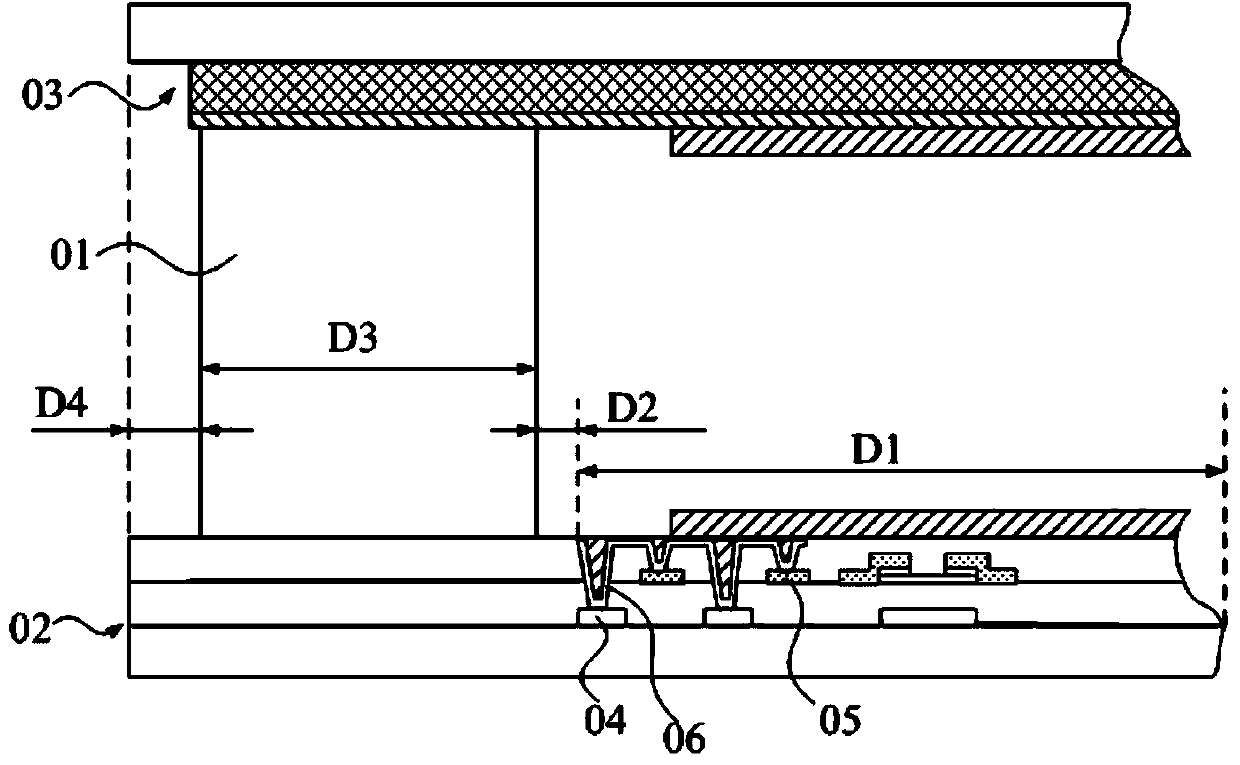

Problems solved by technology

Method used

Image

Examples

Embodiment 1

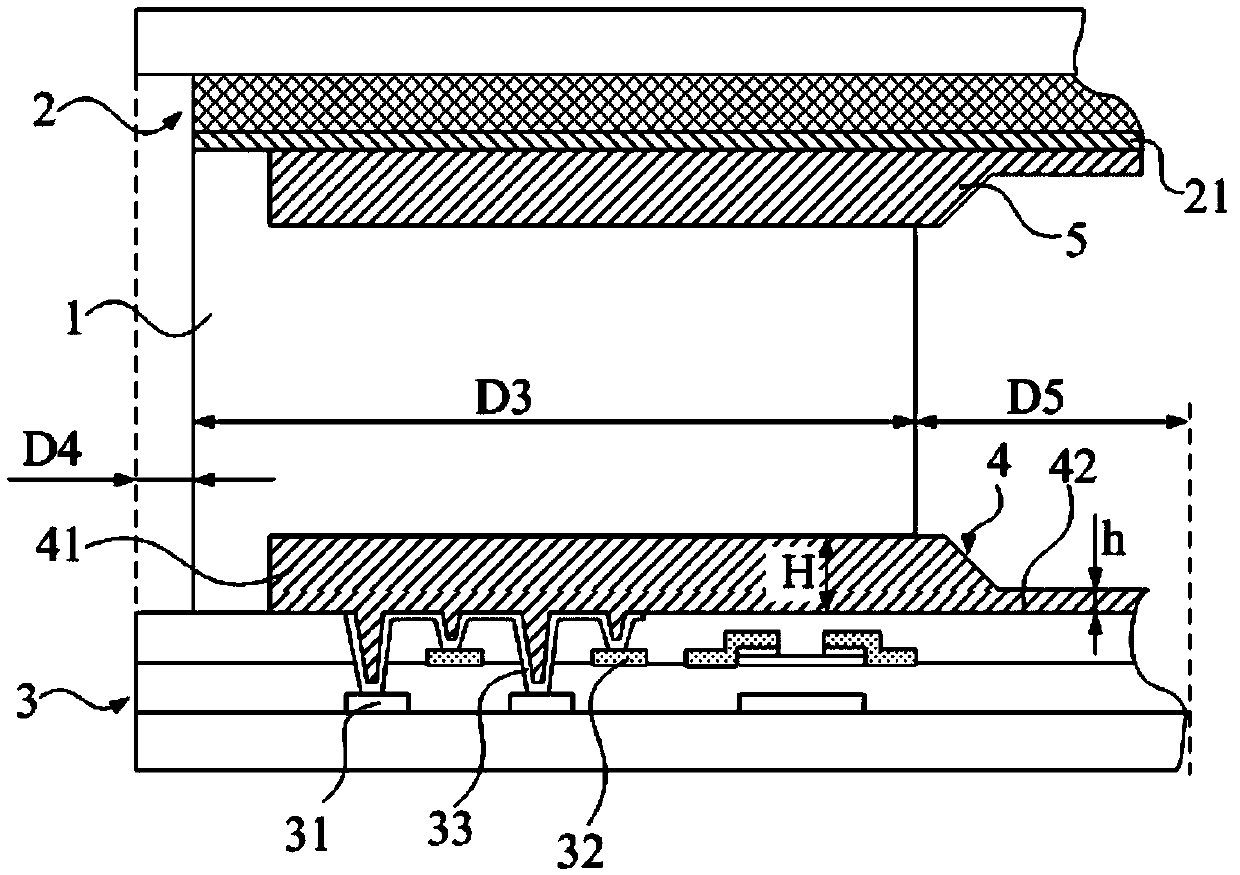

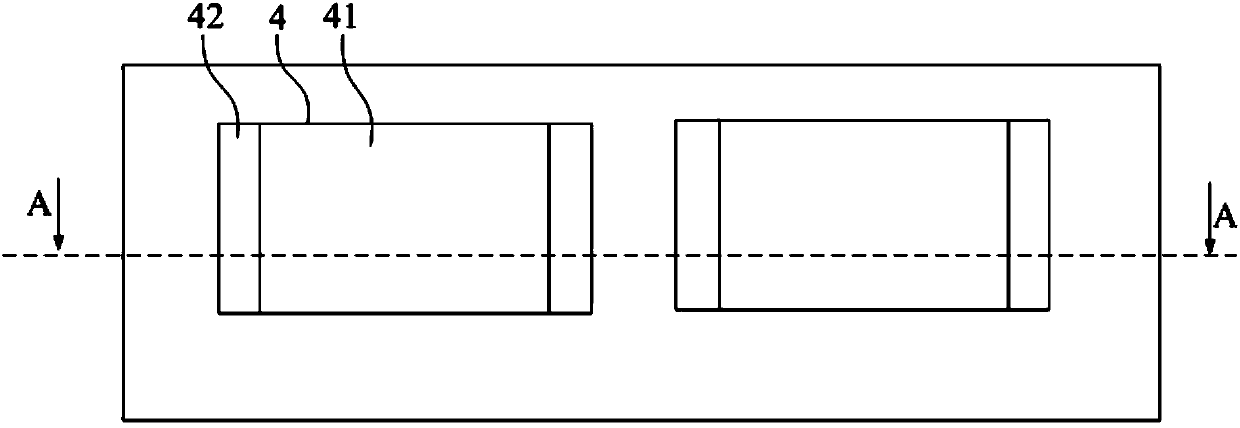

[0033] Please refer to figure 2 , the present embodiment 1 provides a liquid crystal panel, including: a color filter substrate 2 and an array substrate 3 connected in pairs by a sealant 1 doped with gold balls, and the side of the array substrate 3 facing the color filter substrate 2 has a grid Pole shift register, the wiring area of the gate shift register has a conductive electrode 33 connecting the gate electrode 31 and the source and drain electrodes 32; and the side of the color filter substrate 2 facing the array substrate 3 has a common electrode 21; provided in this embodiment The LCD panel also includes:

[0034] The insulating layer located between the conductive electrode 33 and the common electrode 21 , the projection of the insulating layer on the inner side of the array substrate 3 facing the color filter substrate 2 covers the projection of the conductive electrode 33 on the inner side of the array substrate 3 facing the color filter substrate 2 .

[0035]I...

Embodiment 2

[0072] Embodiment 2 of the present invention also provides a liquid crystal display device, which includes the liquid crystal panel provided in Embodiment 1 above.

[0073] Since an insulating layer is provided between the common electrode 21 and the conductive electrode 33 in the liquid crystal panel provided by the above solution, the sealant 1 and the grid can be displaced when the coating width of the sealant 1 is constant. The distance between the registers is very small, and even a part of the sealing glue 1 can be coated on the area directly above the gate shift register to reduce the frame of the liquid crystal panel. In the panel liquid crystal display device, the frame of the liquid crystal display device may also be smaller, so as to facilitate the realization of the narrow frame design of the liquid crystal display device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com