Rotor punching sheet for inner rotor permanent magnet motor

A permanent magnet motor and rotor punching technology, which is applied to the magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of reducing the insulation capacity between sheets, reducing the mechanical strength of the rotor, and difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

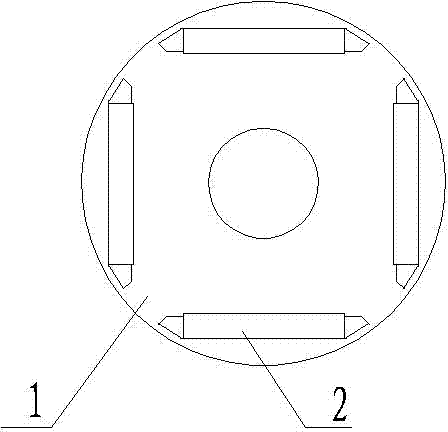

[0018] As attached image 3 As shown, a rotor punching piece of a 4-pole inner rotor permanent magnet motor. The rotor punching piece 1 is a ring-shaped piece. The middle hole of the ring-shaped piece body forms a shaft hole 9. There are 4 uniformly opened on the outer edge of the piece. The trapezoidal groove 8 has the bottom edge of the trapezoidal groove located at the outer edge of the sheet body, and a magnetic steel insertion hole 2 is provided on the sheet body between the two trapezoidal grooves, and the magnetic steel insertion hole 2 is close to the edge of the sheet body.

[0019] As attached image 3 As shown, in this embodiment, the contours of the outer edge of the sheet body between the two trapezoidal grooves are located on the same circular trace 11, and the circle in which the circular trace is located is concentric with the axis 12 of the annular sheet body.

[0020] From the above description, it can be seen that the rotor punching sheet is directly used to punch...

Embodiment 2

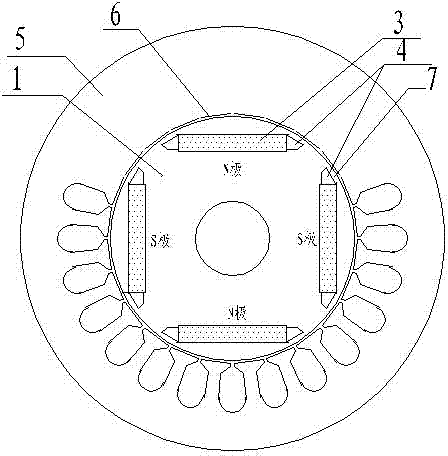

[0025] The rotor punch of the inner-rotor permanent magnet motor provided in Example 1 has a significantly improved performance in preventing magnetic flux leakage between poles compared with the rotor punch in the prior art. However, due to its use of round The ring-shaped sheet body is directly punched, and the outline of the outer edge of the sheet between the two trapezoidal grooves is located on the same circular track, resulting in the same thickness of the air gap of the motor. The structure can be seen attached Figure 5 Show air gap 6. In practical application tests, it is found that the uniform air gap structure is not conducive to weakening the cogging torque, and at the same time, it will increase the eddy current loss caused by the stator winding harmonic magnetic field on the rotor surface, which will have a greater impact on the overall performance of the motor.

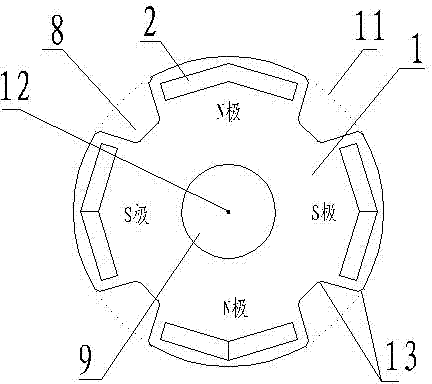

[0026] In order to solve this problem, this embodiment implements further improvements on the basis of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com