Extracting and collecting device and application thereof

A technology of collection device and extraction device, which is applied in the direction of boiler/distillate distillation, steam distillation, etc., to achieve the effect of reducing consumption, reducing condensate consumption and solving losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

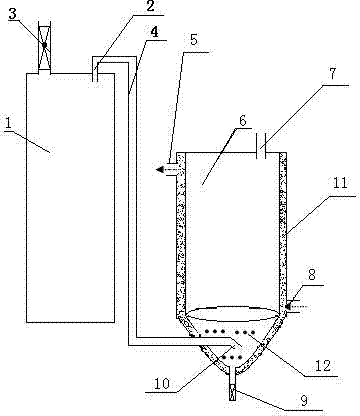

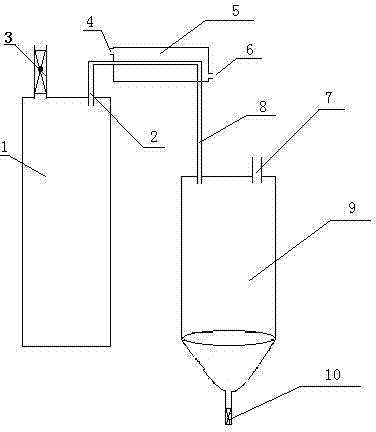

[0017] Embodiment one: if figure 1 as shown,

[0018] figure 1 Shown is an extraction and collection device provided by the present invention, including an extraction device and a condensation collection device. The extraction device includes an extraction tank 1, a safety valve 3, and a pipeline 4. The condensation collection device includes a liquid storage tank 6, an interlayer 11, a condensed water inlet 8, a condensed water outlet 5, an exhaust gas outlet 7, and a liquid drainage device 9.

[0019] The extraction tank 1 is connected to the liquid storage tank 6 through a pipeline 4. During the extraction process, the volatile components distilled out with the steam enter the liquid storage tank 6 through the pipeline 4 to be condensed and collected.

[0020] A safety valve 3 is installed on the top of the extraction tank 1. When the extraction is complete, the safety valve 3 is opened, and the gas is discharged through the safety valve to prevent the distillate collecte...

Embodiment 2

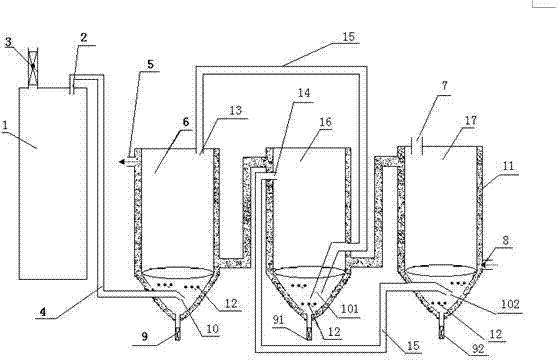

[0024] Embodiment two: if figure 2 as shown,

[0025] figure 2 Shown is an extraction and collection device provided by the present invention, including an extraction device and a condensation collection device. The extraction device includes extraction tank 1, safety valve 3, pipeline 4, and pipeline 15. The condensation collection device includes liquid storage tank 6, liquid storage tank 16, liquid storage tank 17, interlayer 11, condensed water inlet 8, condensed water outlet 5, exhaust gas Outlet 7, liquid discharge device 9, liquid discharge device 91, liquid discharge device 92.

[0026] The extraction tank 1 is connected with the liquid storage tank 6, the liquid storage tank 16 and the liquid storage tank 17 through the pipeline 4 and the pipeline 15, the inlet of the pipeline 4 is connected with the extraction tank outlet 2, and the volatile components distilled out in the extraction tank are exported through the extraction tank 2. Enter the liquid storage tank ...

Embodiment 3

[0029] Embodiment three: use the extraction and collection of paeonol in Moutan cortex to illustrate the device of the present invention and its use and effect

[0030] Cortex Moutan 20.0kg is placed in the extraction tank 1 of the extraction and collection device described in embodiment 2, and an appropriate amount of water is added to the liquid storage tanks 6, 16, and 17. Steam and condensate, distillation, extraction, collection. The steam pressure is 0.10-0.12Mpa, and the condensed water flow rate is 1.0 tons / hour.

[0031] Collect distillate 200kg after distillation finishes.

[0032] The distillate was placed in a refrigerator at 4°C for paeonol crystallization, and a total of 0.42 kg of paeonol crystals were obtained. The yield of paeonol was calculated. , extract paeonol in Cortex Moutan with device in embodiment 2, and its yield is 2.10%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com