Granulation knife sealing structure of wet mixing granulator

A sealing structure and wet mixing technology, applied in the direction of granulation in static tanks/troughs, etc., can solve the problems of motor service life impact, cumbersome maintenance work, time-consuming and other problems, and achieve convenient maintenance, simple cleaning work, and reliable sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

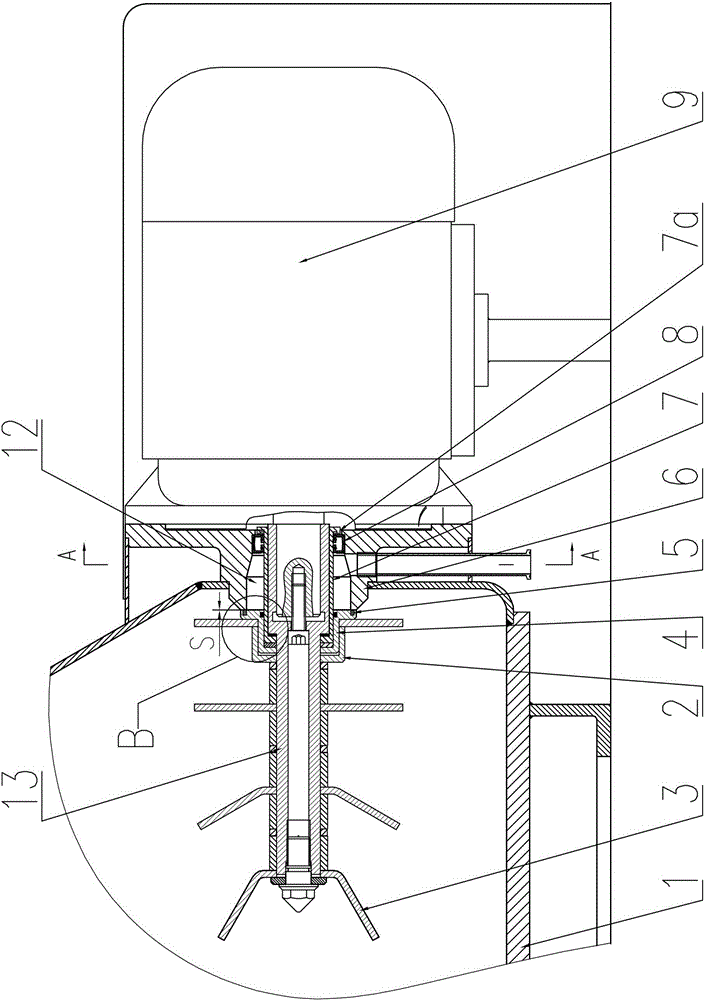

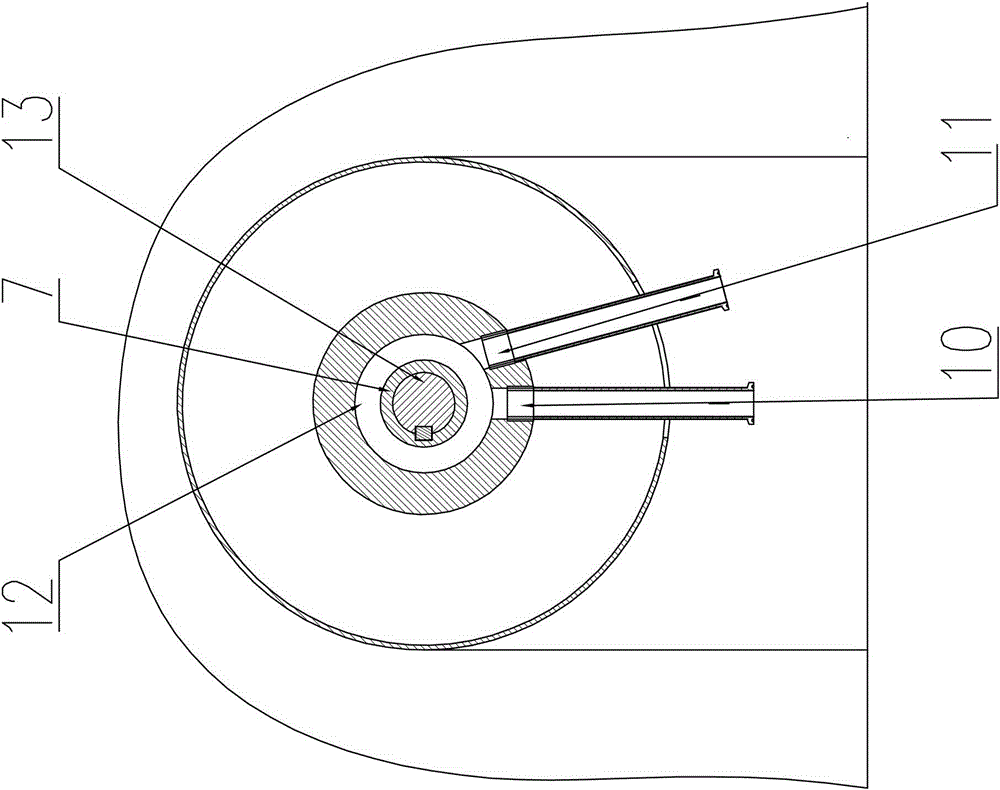

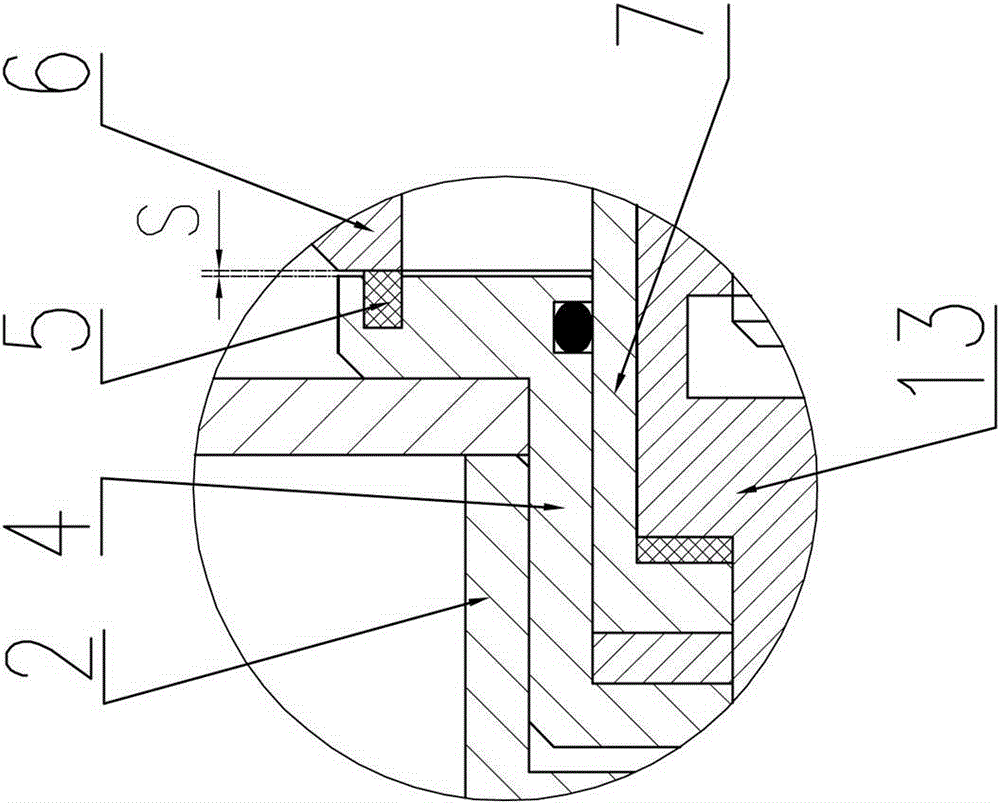

[0014] like figure 1 , figure 2 , image 3 As shown, an embodiment of the sealing structure of the granulation knife of the wet mixing granulator of the present invention is arranged between the material cylinder 1 and the granulation transmission device, and the granulation transmission device includes a granulation knife transmission shaft 13. The sealing structure of the granulating knife includes a granulating knife flange seat 6 fixedly welded on the material cylinder 1, a seal 8, a friction sleeve 7, a sealing cover 4, and a PTFE ring 5. The flange seat 6 of the granulating knife has a flange hole, and in order to facilitate the one-way disassembly and assembly in the direction of the material cylinder 1, this embodiment adopts a flange hole consisting of the front part of the conical cavity structure and the cylindrical cavity structure. The granulation knife flange seat 6 that the rear part constitutes. The granulating knife transmission shaft 13 passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com