Multifunctional engine assembling table

A technology of engines and assembly tables, applied in assembly machines, workpiece clamping devices, metal processing equipment, etc., can solve the problems of high-efficiency labor in production and assembly, facilitate production arrangements and quota management, reduce overall weight, and reduce floor space small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

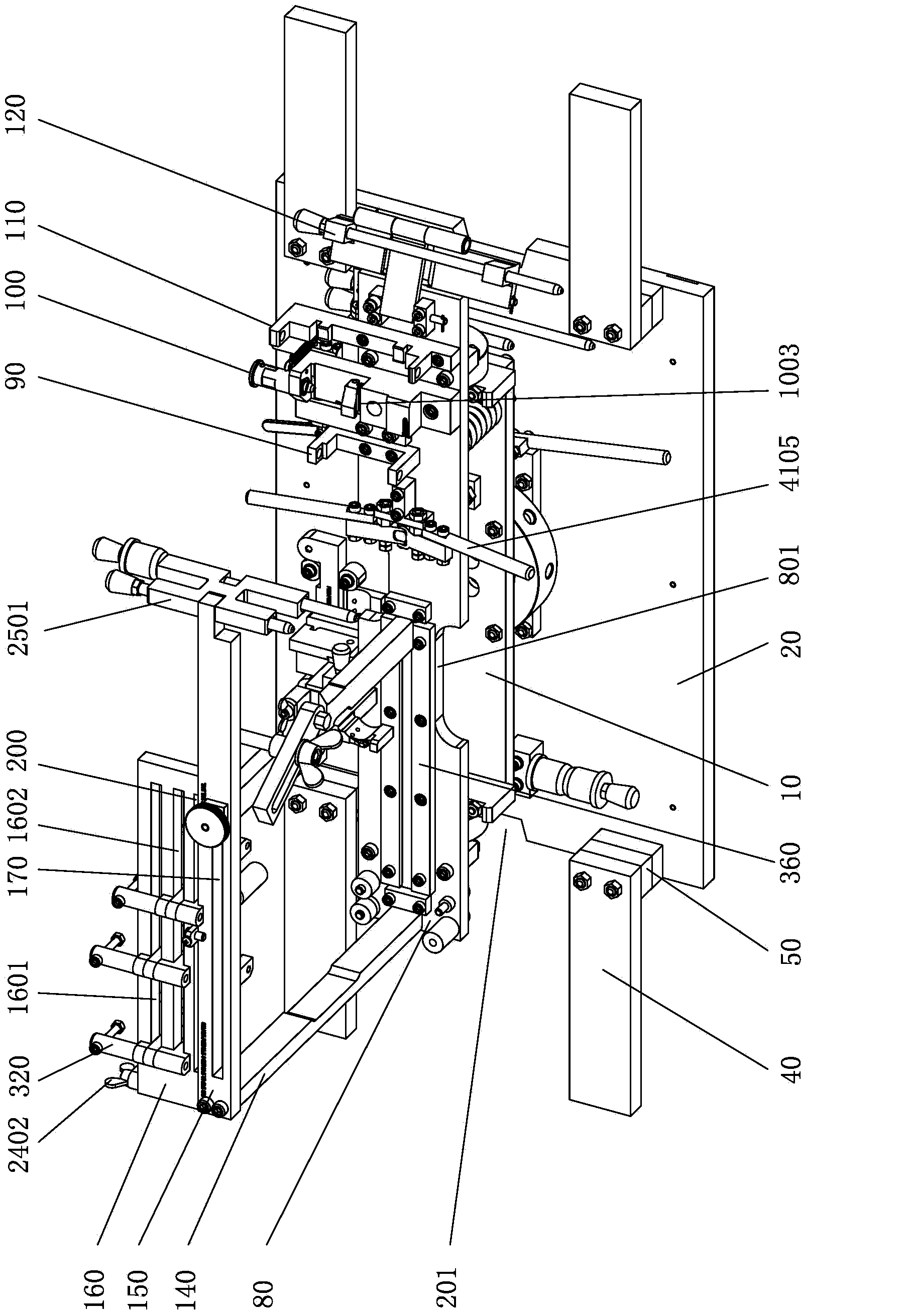

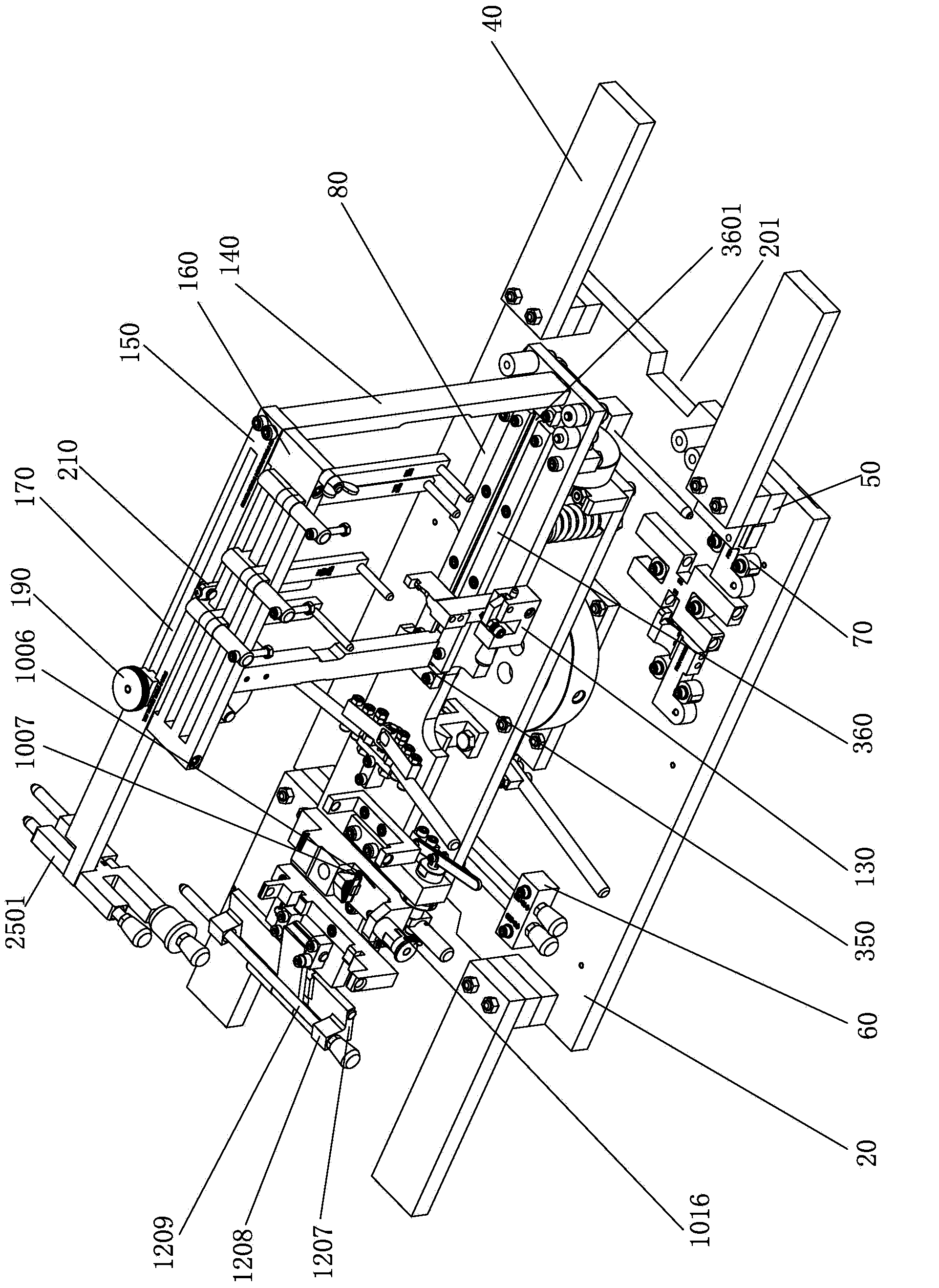

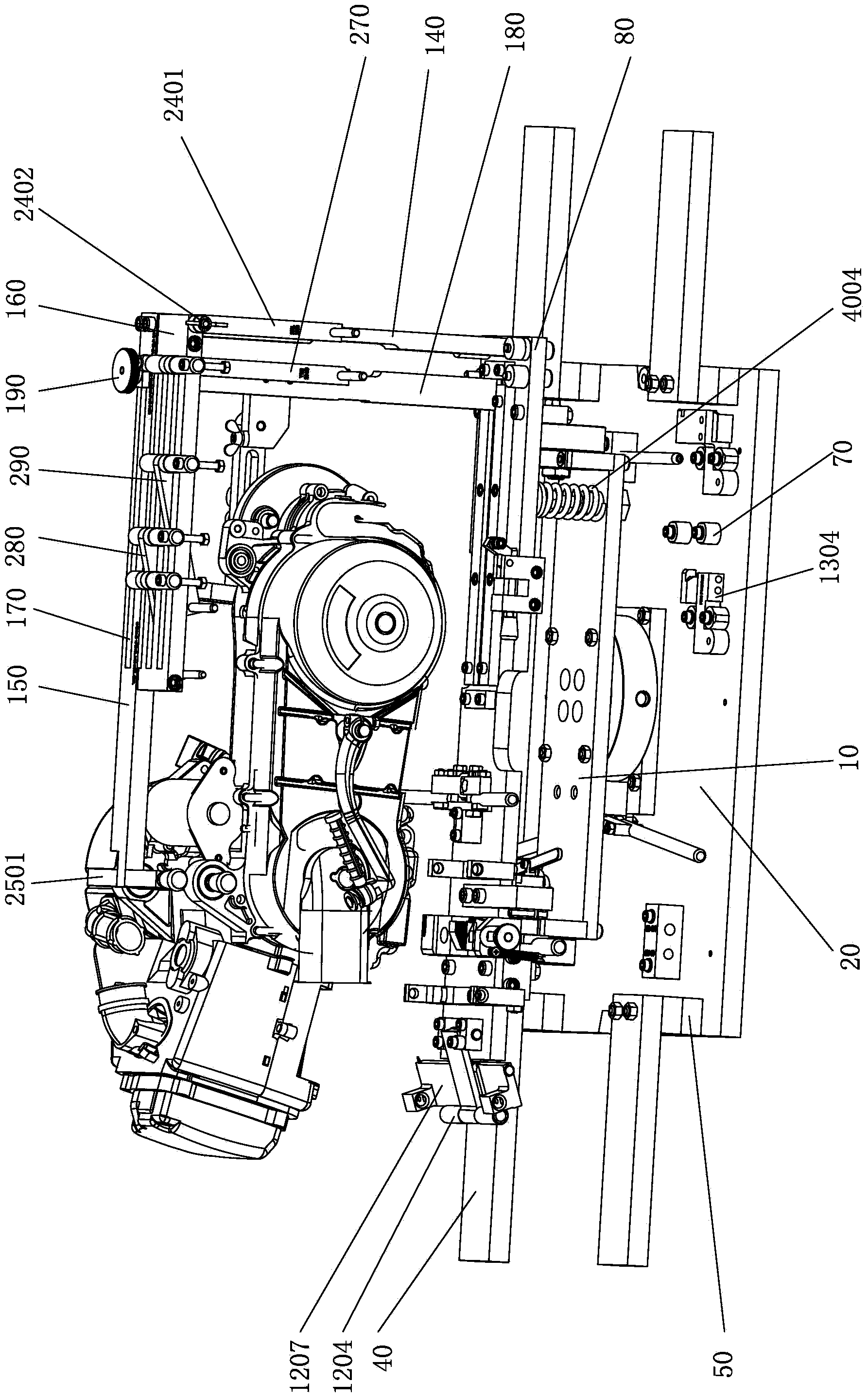

[0068] The present invention will be further described below with specific embodiment, see figure 1 —30:

[0069] A multi-functional engine assembly platform, the base is provided with a combined bottom plate 10 that can rotate horizontally around the turntable, the combined bottom plate 10 is provided with an engine case fixing device, and the engine case fixing device can be mounted on the combined bottom plate 10 to Forward or backward deflection.

[0070] The above-mentioned base is an assembly line moving seat, which is provided with an inlay 30 that can move on the rollers on the assembly line on the bottom plane of the assembly line moving seat bottom plate 20, specifically on the bottom plane of the moving seat bottom plate 20. Fixed hard trim. The inlay 30 has a wear-resistant effect. In this way, the bottom plate 20 of the assembly line movable seat can be replaced by a plastic plate to reduce the weight and manufacturing cost, thereby significantly reducing the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com