A constant tension pay-off stand

A pay-off frame and constant tension technology, which is applied in the field of pay-off racks, can solve the problems of inapplicability, power loss, and complex structure of conductive cables, and achieve the effects of timely adjustment, simple control, and small number of adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

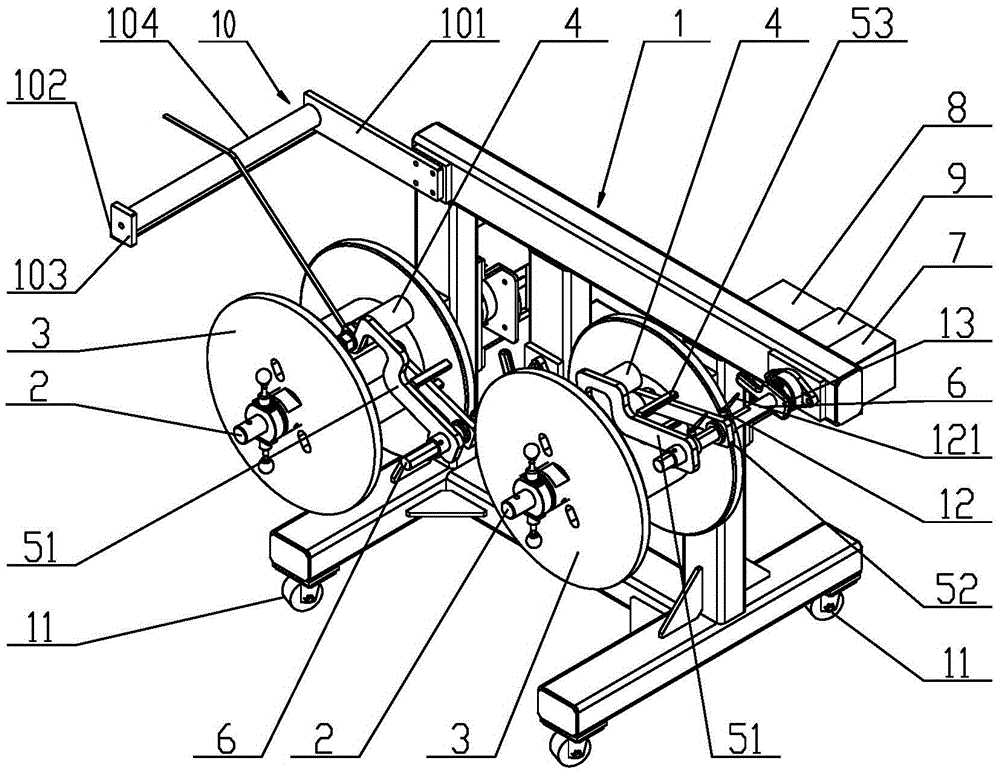

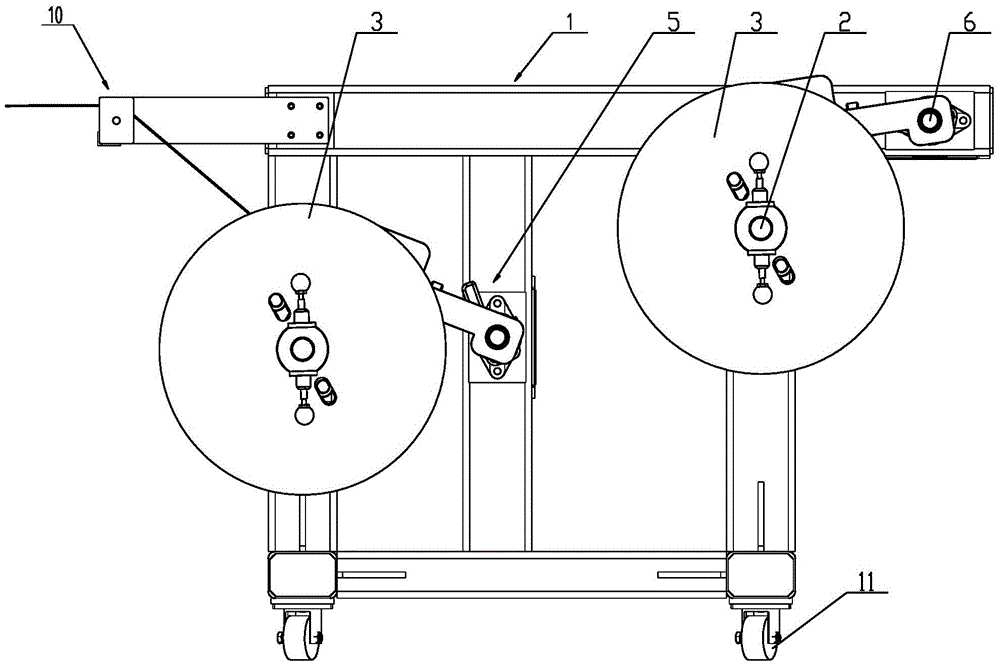

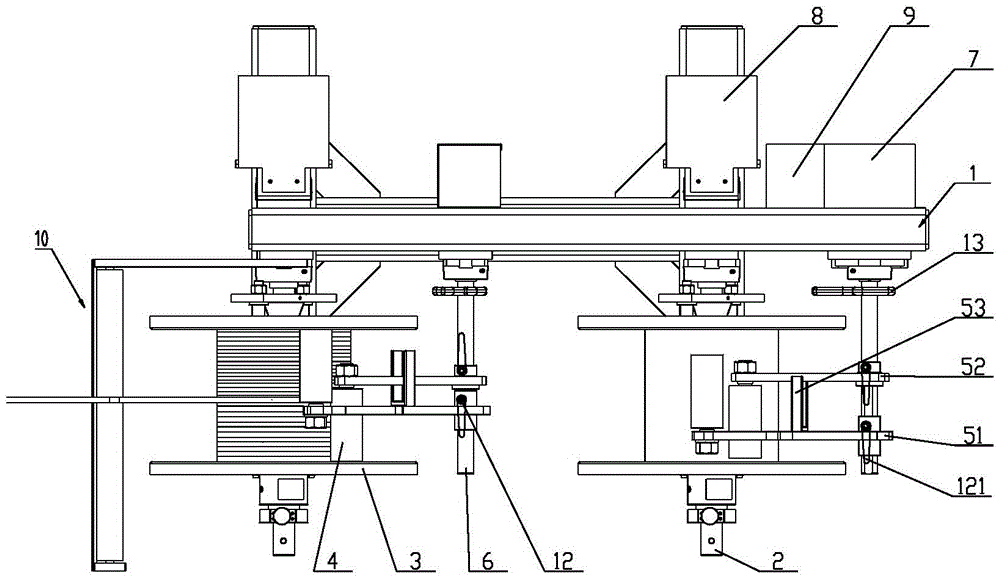

[0037] like Figure 1 to Figure 3 As shown, a constant tension pay-off frame of the present invention includes a bobbin 2 arranged on the frame 1, and a bobbin 3 is installed on one side of the bobbin 2. When the bobbin 2 rotates, the bobbin 3 is The winding shaft 2 drives the synchronous rotation. A stopper 8 is installed on the other side of the spool 2 .

[0038] The frame 1 is also provided with a pressing roller shaft 6 , one side of the pressing roller shaft 6 is mounted with a pressing roller arm group 5 and a pressing roller handle 13 , and the other side is mounted with an angle sensor 7 . The pressing roller shaft 6 is a circular shaft, one end of the first pressing roller arm 51 and the second pressing roller arm 52 is sleeved on the pressing roller shaft 6, and the first pressing roller arm 51 and the second pressing roller arm 52 are connected with the pressing roller shaft. There is a screw hole matched with the top screw 12, the pressing roller shaft is provid...

Embodiment 2

[0046] The difference between this preferred embodiment and the first preferred embodiment is that this preferred embodiment further includes a set of alignment rollers 10 .

[0047] like Figure 1 to Figure 3As shown, the set of alignment rollers 10 includes a roller support plate 101 , a roller angle iron 102 , a roller support plate 103 and a roller shaft 104 . The roller shaft group 10 is located on the side of the bobbin 3 away from the pressing roller shaft and is not lower than the upper top surface of the bobbin when the maximum winding is performed. The roller support plate 101 is a rectangular iron plate, which is fixedly connected to the upper corner of the frame 1 . The roller angle iron 102 is fixedly connected with the roller support plate 101 at 90 degrees and is parallel to the ground. One end of the roller angle iron 102 is connected to the roller support plate 101 , and the other end is fixedly connected to the roller support plate 103 . A roller shaft 104...

Embodiment 3

[0050] The difference between this preferred embodiment and the first or second preferred embodiment is that the frame 1 can be welded by square steel, channel steel, angle iron or a combination thereof, or can be detachably installed. The positions of the winding shaft 2 and the pressing roller shaft 6 on the frame 1 are not limited, and the number is not limited. The installation position of the angle sensor 7 is not limited, as long as it can receive the angle change signal when the roller arm group 5 rotates. The installation position of the controller 9 is not limited, as long as it can receive the signal output by the angle sensor 7 and transmit the output signal of the controller 9 to the brake 8 . The installation position of the brake 8 is not limited, as long as it can receive the output signal of the controller 9 and control the torque of the bobbin 2 . The installation position of the pressing roller handle 13 is not limited, as long as it does not interfere with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com