Solution method used for preparing cesium tin triiodide thin films

A cesium tin triiodide, solution method technology, applied in chemical instruments and methods, inorganic chemistry, tin compounds, etc., can solve problems such as CSI samples cannot be carried out, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

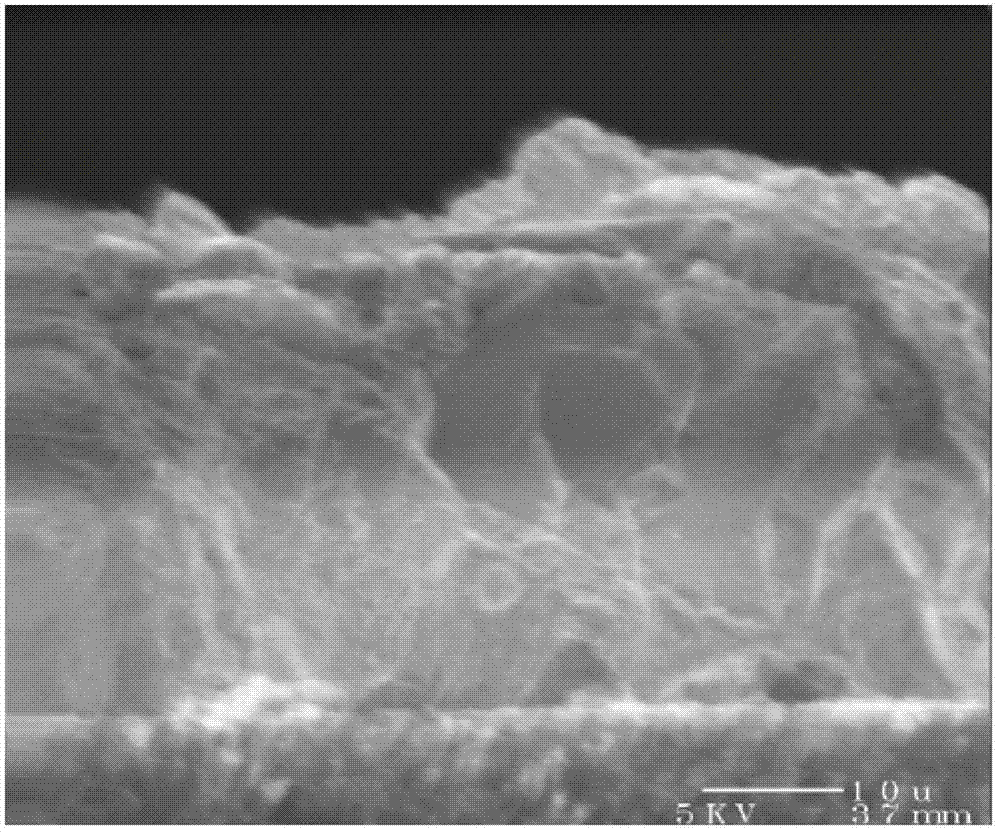

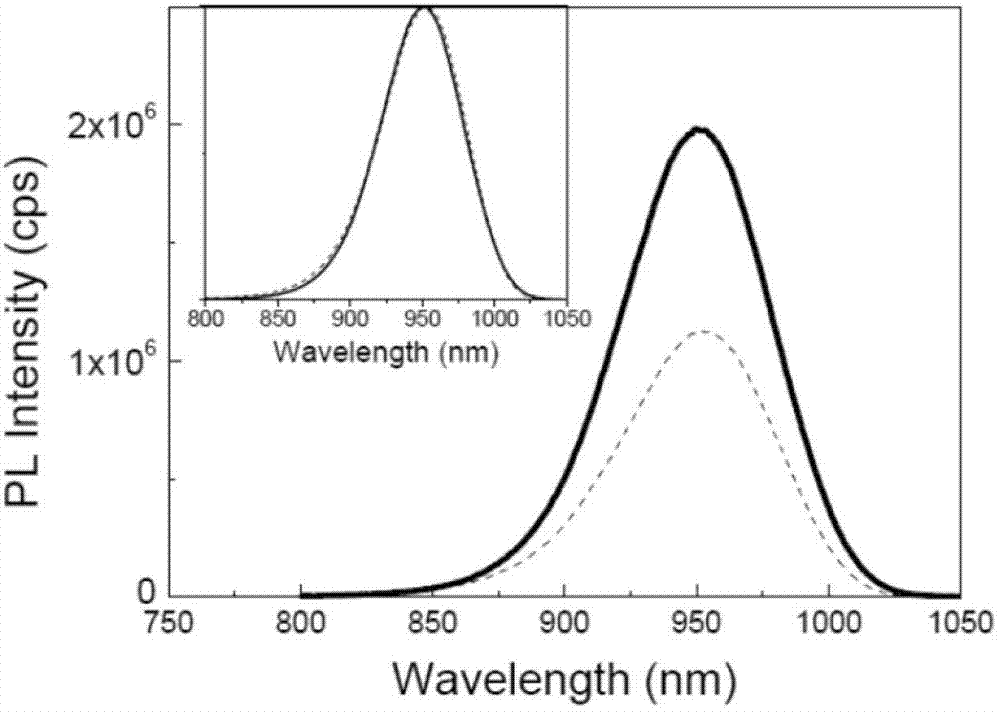

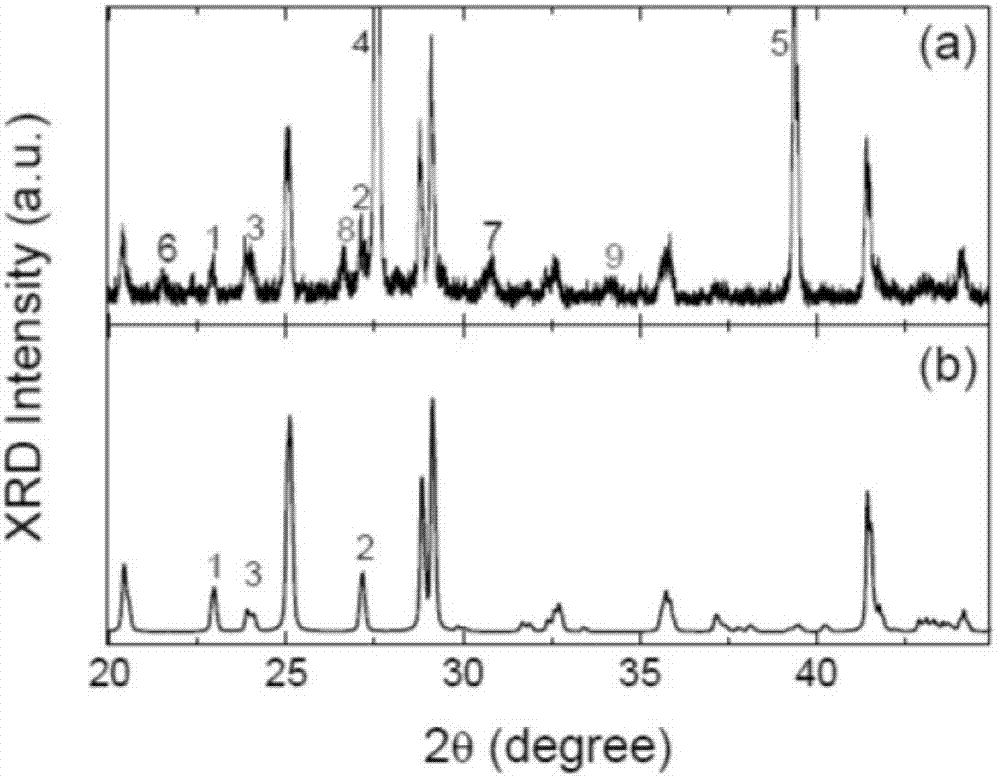

[0036] Solution Synthesis of Polycrystalline CsSnI 3 The film steps are as follows:

[0037] The solution of the precursor material is synthesized under ambient conditions, and the ambient conditions refer to: room temperature or temperature of 298.15K (or 25°C, 77°F); absolute pressure of 100kPa (or 14.504psi, 0.986atm).

[0038] The concrete preparation method of CsI solution is as follows:

[0039] 12 grams of CsI powder with a purity of 99.9% was added to 30 grams of deionized water to form a 28.6 wt% (weight percent) CsI solution. The CsI powder was completely dissolved in deionized water, and the CsI solution was stirred for 30 minutes. Under ambient conditions, the CsI solution is colorless and stable, and more CsI powder can be added to the deionized aqueous solution of CsI until saturated, the solution is colorless, and the CsI powder can be dissolved in water less than its own mass without obvious break down.

[0040] It is also possible to select a solvent other ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com