Preparation method of ceramic coating on surface of sintered NdFeB permanent magnet

A ceramic coating and NdFeB technology, which is applied in the field of preparation of ceramic coatings on the surface of sintered NdFeB permanent magnets, to achieve the effects of simple industrial application, extended service life and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

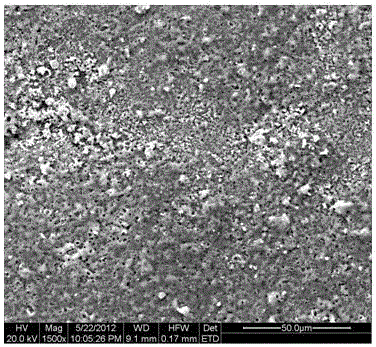

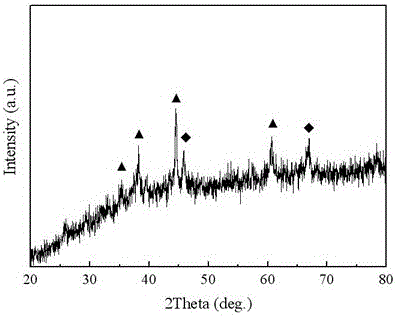

Image

Examples

Embodiment 1

[0009] The preparation method of the ceramic coating on the surface of the sintered NdFeB permanent magnet in this embodiment is carried out according to the following steps:

[0010] (1) Chamfering and polishing: use mechanical vibrating and rolling chamfering methods to perform surface polishing on 38SH sintered NdFeB permanent magnets, and the final size is 30×15×4mm;

[0011] (2) Degreasing and degreasing: put the chamfered magnet into a 60°C alkaline degreasing agent (the main components are sodium carbonate, sodium phosphate, sodium silicate and emulsifier, etc.) for 10 minutes to degrease and degrease;

[0012] (3) Pickling and derusting: put in 5% HNO 3 The solution is pickled and derusted for 30s;

[0013] (4) Micro-arc oxidation: Put the permanent magnet after pickling and rust removal into the electrolyte for micro-arc oxidation treatment. The electrolyte is a sodium aluminate system, that is, sodium aluminate and potassium dihydrogen phosphate with deionized water...

Embodiment 2

[0017] The preparation method of the ceramic coating on the surface of the sintered NdFeB permanent magnet in this embodiment is carried out according to the following steps:

[0018] (1) Chamfering and polishing: use mechanical vibrating and rolling chamfering methods to perform surface polishing on 38SH sintered NdFeB permanent magnets, and the final size is 30×15×4mm;

[0019] (2) Degreasing and degreasing: put the chamfered magnet into a 60°C alkaline degreasing agent (the main components are sodium carbonate, sodium phosphate, sodium silicate and emulsifier, etc.) for 10 minutes to degrease and degrease;

[0020] (3) Pickling and derusting: put in 10% HNO 3 The solution is pickled and derusted for 20s;

[0021] (4) Micro-arc oxidation: Put the permanent magnet after pickling and rust removal into the electrolyte for micro-arc oxidation treatment. The electrolyte is potassium fluozirconate system, that is, potassium fluozirconate and phosphoric acid are prepared with deio...

Embodiment 3

[0025] The preparation method of the ceramic coating on the surface of the sintered NdFeB permanent magnet in this embodiment is carried out according to the following steps:

[0026] (1) Chamfering and polishing: use mechanical vibrating and rolling chamfering methods to perform surface polishing on 38SH sintered NdFeB permanent magnets, and the final size is 30×15×4mm;

[0027] (2) Degreasing and degreasing: put the chamfered magnet into a 60°C alkaline degreasing agent (the main components are sodium carbonate, sodium phosphate, sodium silicate and emulsifier, etc.) for 10 minutes to degrease and degrease;

[0028] (3) Pickling and derusting: put in 10% HNO 3 The solution is pickled and derusted for 20s;

[0029] (4) Micro-arc oxidation: Put the permanent magnet after pickling and rust removal into the electrolyte for micro-arc oxidation treatment. The electrolyte is potassium fluorotitanate system, that is, potassium fluorotitanate and dipotassium hydrogen phosphate are d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com