Blowing-type high heat stove

A blast furnace and blast-type technology, which is applied in the field of blast-type blast furnaces, can solve problems such as poor ignition and danger, and achieve the effects of avoiding danger, full combustion, and high flame heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

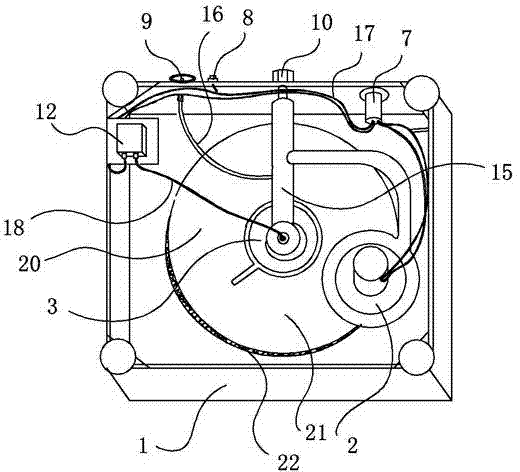

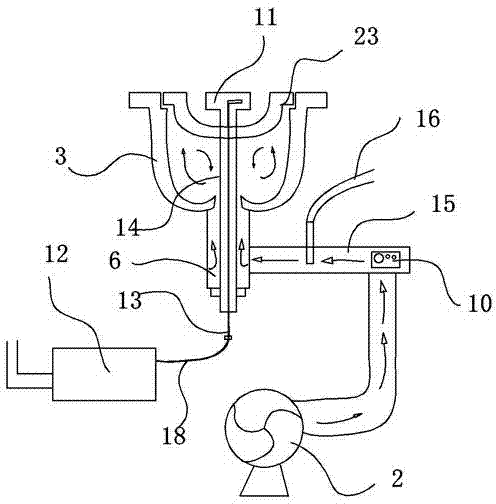

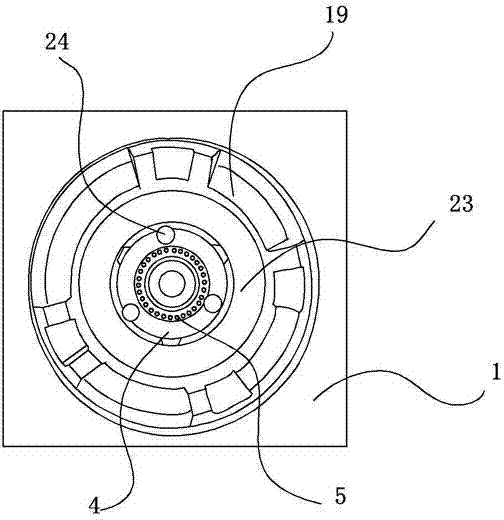

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] Such as Figure 1-Figure 4 Shown, a kind of blast type fierce furnace, it is made up of body of furnace 1, hob 19, burner, ignition device, blower 2 and control valve, and described burner is arranged at the center of body of furnace 1, and blower 2 is arranged at One side of the burner, the burner includes a furnace 3, a refractory furnace ring 4 and a combustion hole 5, the combustion holes 5 are evenly arranged on the refractory ring 4, the diameter of the refractory ring 4 is 2.0-2.5cm, and the fire ring 23 is sleeved The refractory ring 4 and the fire ring 23 have a diameter of 2.8-3.3 cm. The lower end of the furnace hall 3 is provided with an extension pipe 6, and the extension pipe 6 is connected to the furnace hall 3. The control valve includes a power switch 7, a pulse switch 8, and an air intake valve. 9 and the damper adjustment hand...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap