Full-automatic firecracker reeling machine

A reel machine, fully automatic technology, applied in pyrotechnics, cardboard winding articles, offensive equipment, etc., can solve the problems of poor product quality, hidden safety hazards, low work efficiency, etc., and achieve reliable performance, convenient maintenance, and high efficacy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

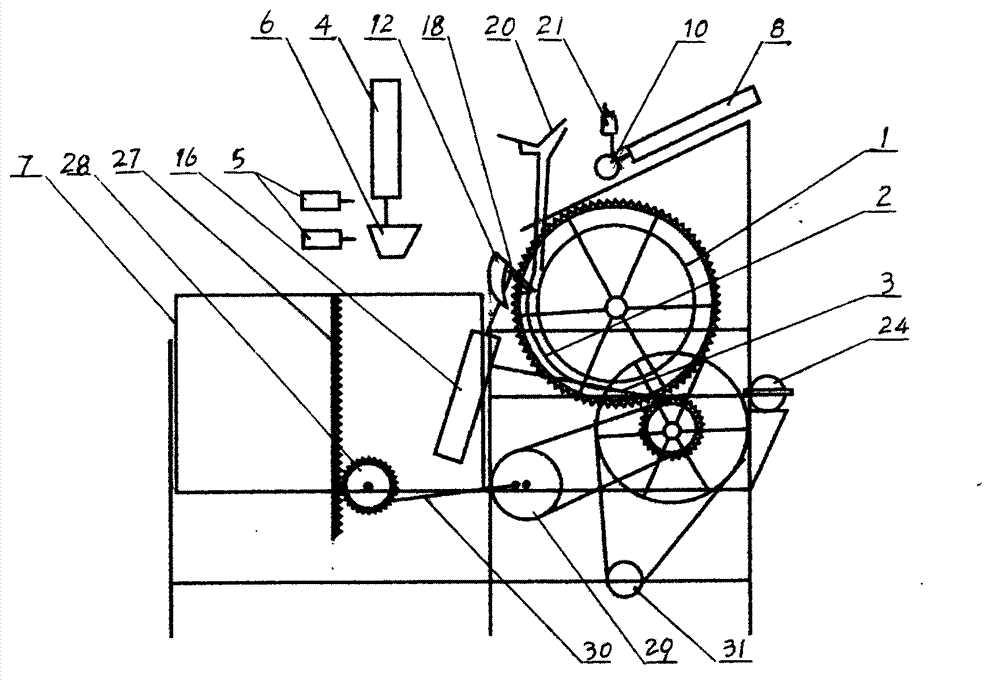

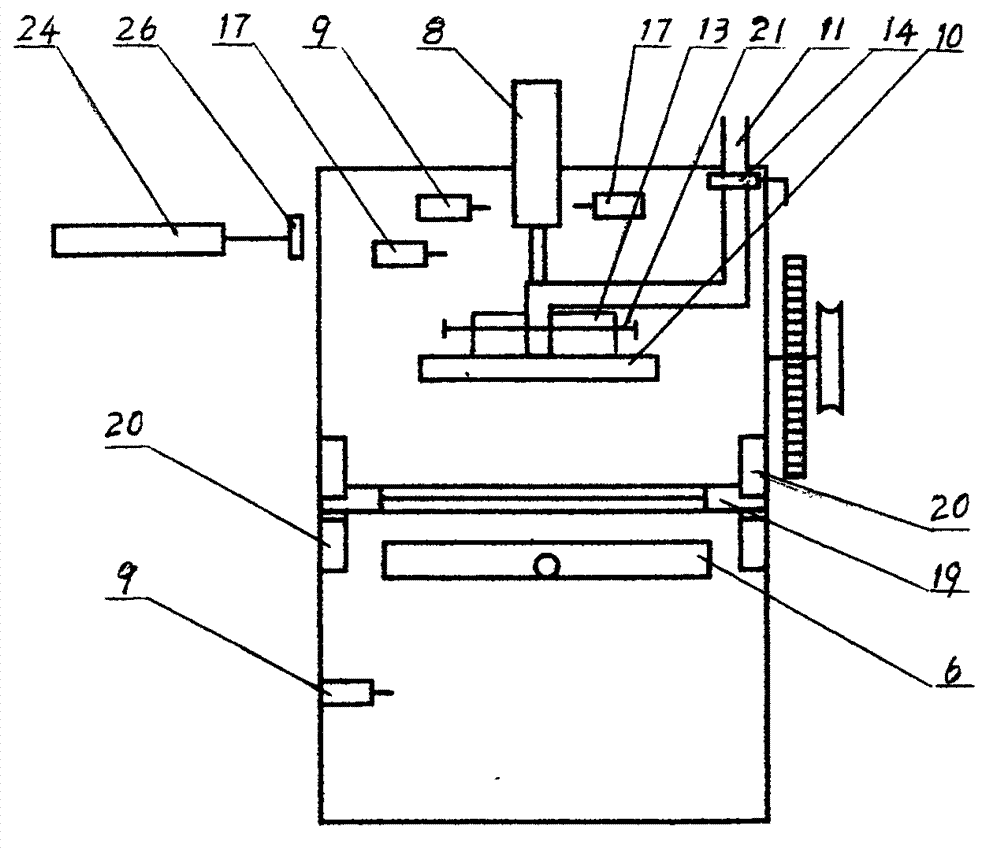

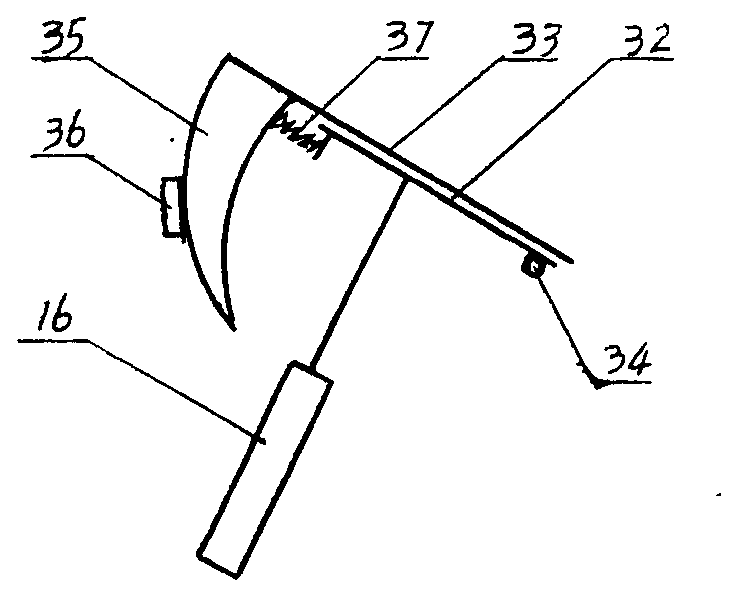

[0026] Refer to attached figure 1 with 2 , the present invention is made up of rubbing cylinder (1), rubbing plate (2) and blade set (3), and simultaneously sets grouting mechanism, paper feeding mechanism, core feeding structure and core pulling structure, thus has realized the fully automatic Production. The grouting mechanism is composed of a grouting cylinder (4) and its travel switch (5) and a slurry storage tank (6), which is installed above the paper putting platform (7). The bottom surface of the slurry storage tank is provided with a number of seepage micro-holes or covered with flannelette. make. A toothed guide rail (27) is set vertically below the paper platform and meshes with the guide rail flywheel (28). The flywheel is turned by the lever (30) on the lever wheel (29), and the lever wheel is driven by the motor (31) through the belt. The belt pulley on the shaft is connected so that the platform rises slowly as the roll paper is continuously reduced during th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com