Method for detecting presence of thermo-responsive point related with thermal deformation of main shaft

A thermally sensitive point, thermal deformation technology, applied in instruments, computer control, simulators, etc., can solve problems such as difficult to apply thermal error compensation of machine tools, poor robustness of thermal error models, and no solution to the distribution law. The effect of wide range, improving machining accuracy and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

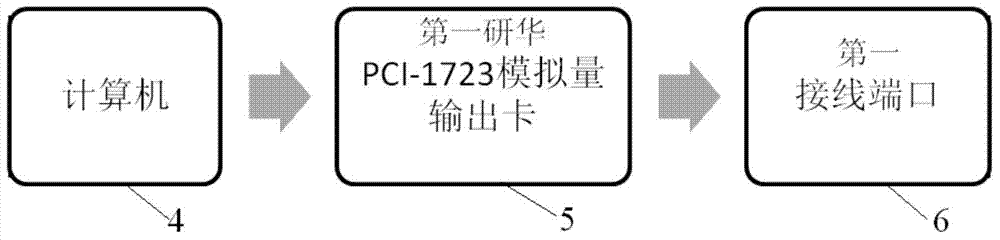

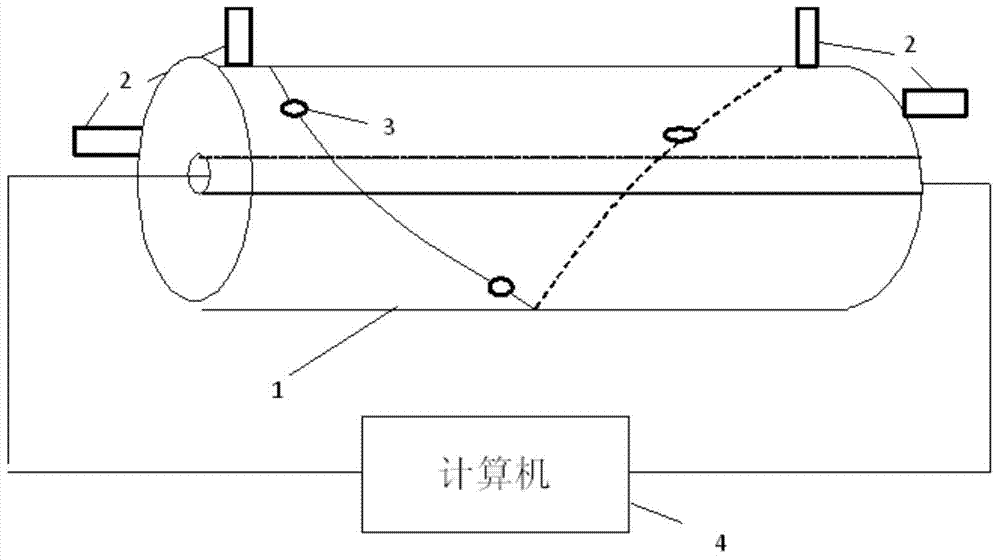

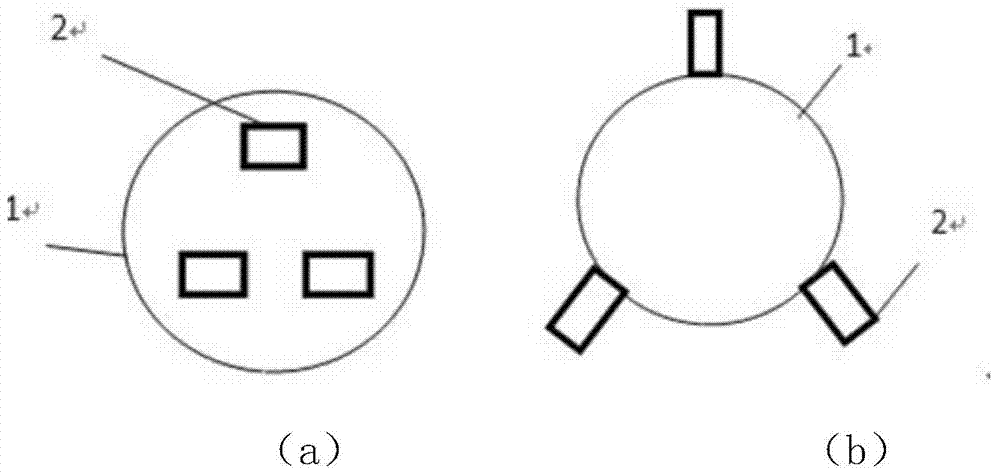

[0020] refer to Figure 1-4 , a device for detecting the existence of thermally sensitive points related to the thermal deformation of the main shaft, including four parts: a mechanical system, a power control system, a measurement system and a data processing system, the mechanical system includes a main shaft 1, and the power control system includes Control the output power of the heating element and install the computer with Labview software 4, the first Advantech PCI-1723 analog output card 5, the first wiring port 6 and the heating element, such as figure 1 shown. The measurement system includes a thermistor 3, an eddy current sensor 2, a conditioning module 7, a second wiring port 8, and a second Advantech PCI-1712 32-way analog output card 9, such as Figure 4 shown. Among them, the spindle center hole is obtained by drilling a hole in the spindle center al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com