Binocular vision measurement system camera parameter online adjustment method

A technology of binocular vision measurement and camera parameters, which is applied in measurement devices, image data processing, image analysis, etc., can solve the problems of orthogonality influence of high-precision motion platform, complex forging site environment, long calibration time, etc. It is used for online adjustment, high precision, and the effect of improving measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

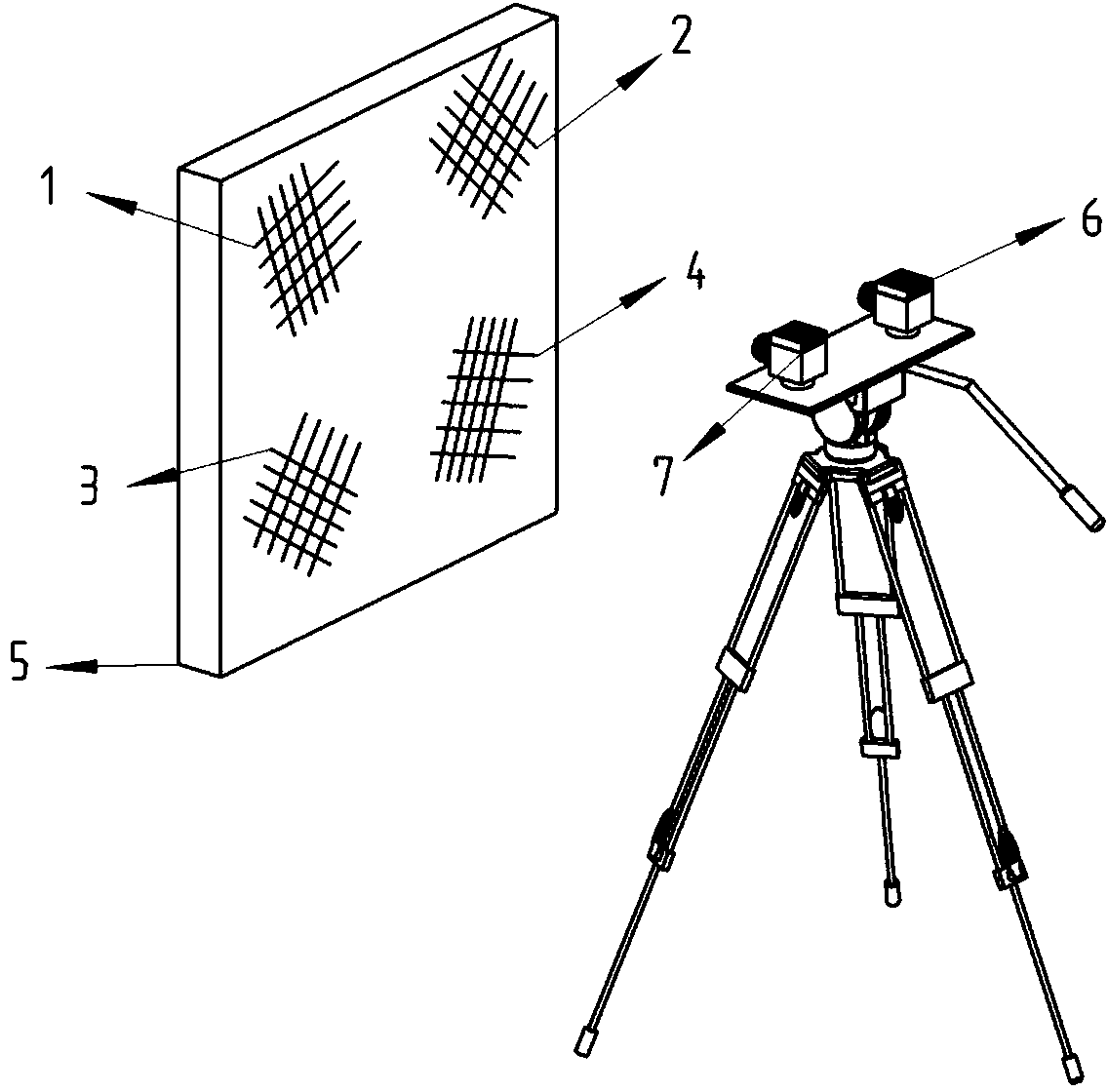

[0036] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and technical solutions.

[0037] Camera calibration actually requires the internal parameter matrix K, the rotation and translation matrices R and T between the two cameras. A general camera model can be expressed as:

[0038]

[0039] Among them, (X w ,Y w ,Z w ,1) Tis the secondary coordinate of the space point in the world coordinate system, (x,y,1) T is the corresponding image point of the spatial point in the image coordinate system, f x , f y is the equivalent focal length of the camera, u 0 , v 0 is the coordinate of the principal point where the optical axis passes through the image plane, and z is the scaling factor.

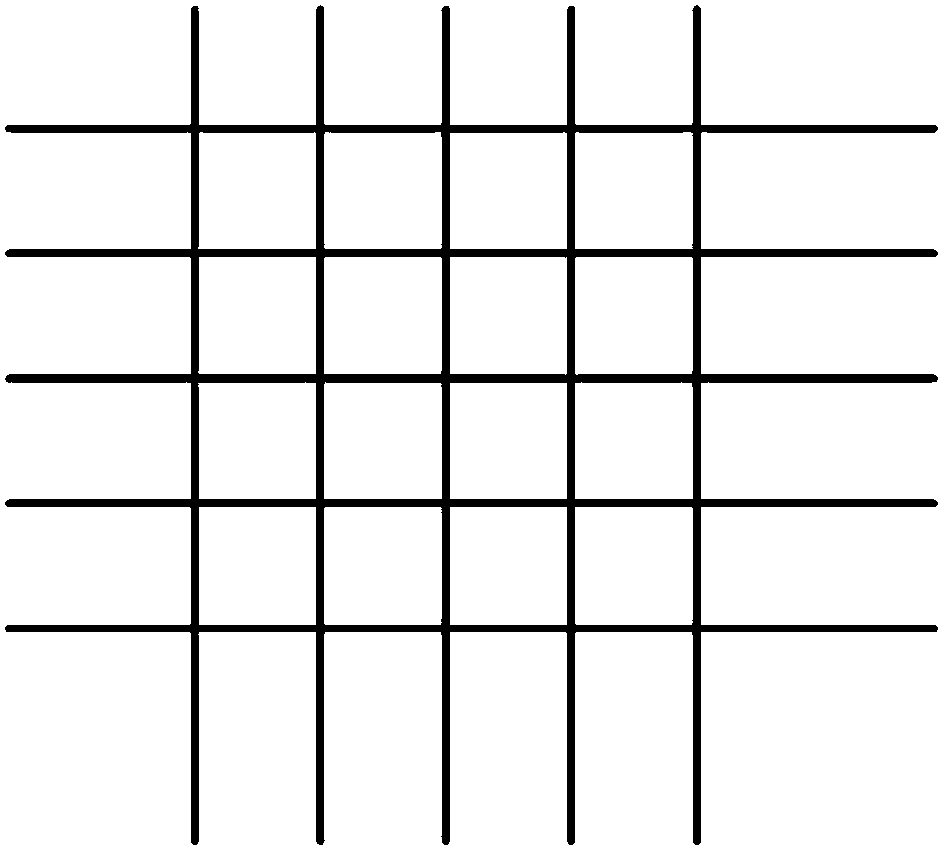

[0040] Step 1: Make 4 camera parameter adjustment templates

[0041] Make 4 camera parameter adjustment templates, the camera parameter adjustment templates are as follows figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com