Simple method and connection structure for preventing resistance increase due to contact of copper hard busbar and aluminum hard busbar

A connection structure and contact resistance technology, which is applied in the direction of conductive connection, connection, connection contact material, etc., can solve the problems of increased resistance at the connection point, increased contact resistance, etc., and achieves convenient connection operation, light weight, and reduced connection costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

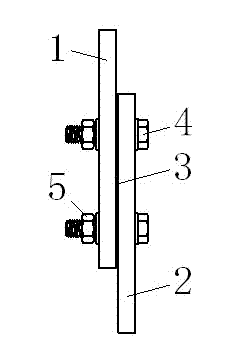

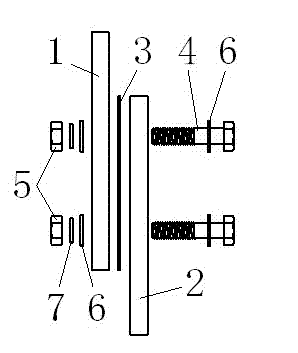

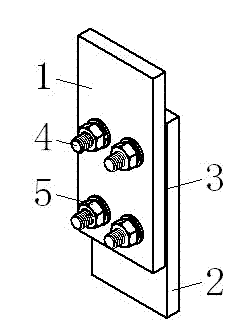

[0025] In specific implementation, such as Figure 4 As shown, first cut a piece of copper foil paper with copper foil paper corresponding to the size and shape of the connecting surface of copper hard bus 1 and aluminum hard bus 2 according to the connection surface of copper hard bus 1 and aluminum hard bus 2; The copper foil paper is completely immersed in the melted solder for 30 seconds and then taken out, so that the solder is evenly distributed on the surface of the copper foil paper to form a tin-lined copper foil paper 3; compare the position and size of the fastening hole 8 of the copper hard bus bar 1 and the aluminum hard bus bar 2 , Open the fastening hole 8 on the tin-lined copper foil paper 3; polish the connecting surface of the copper hard busbar 1 and the aluminum hard busbar 2 with 0# sandpaper, remove the oxide layer, and apply a thin layer of conductive paste or electric compound Grease 9 to prevent oxidation; sandwich the tin-lined copper foil paper 3 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com