Method for splicing and connecting precast reinforced concrete floor slabs within span

A technology of reinforced concrete and lap joints, which is applied to floors, building components, buildings, etc., can solve the problems of difficult construction, time-consuming, time-consuming and high cost, and achieve the effects of easy quality assurance, simple manufacturing and construction processes, and accelerated construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

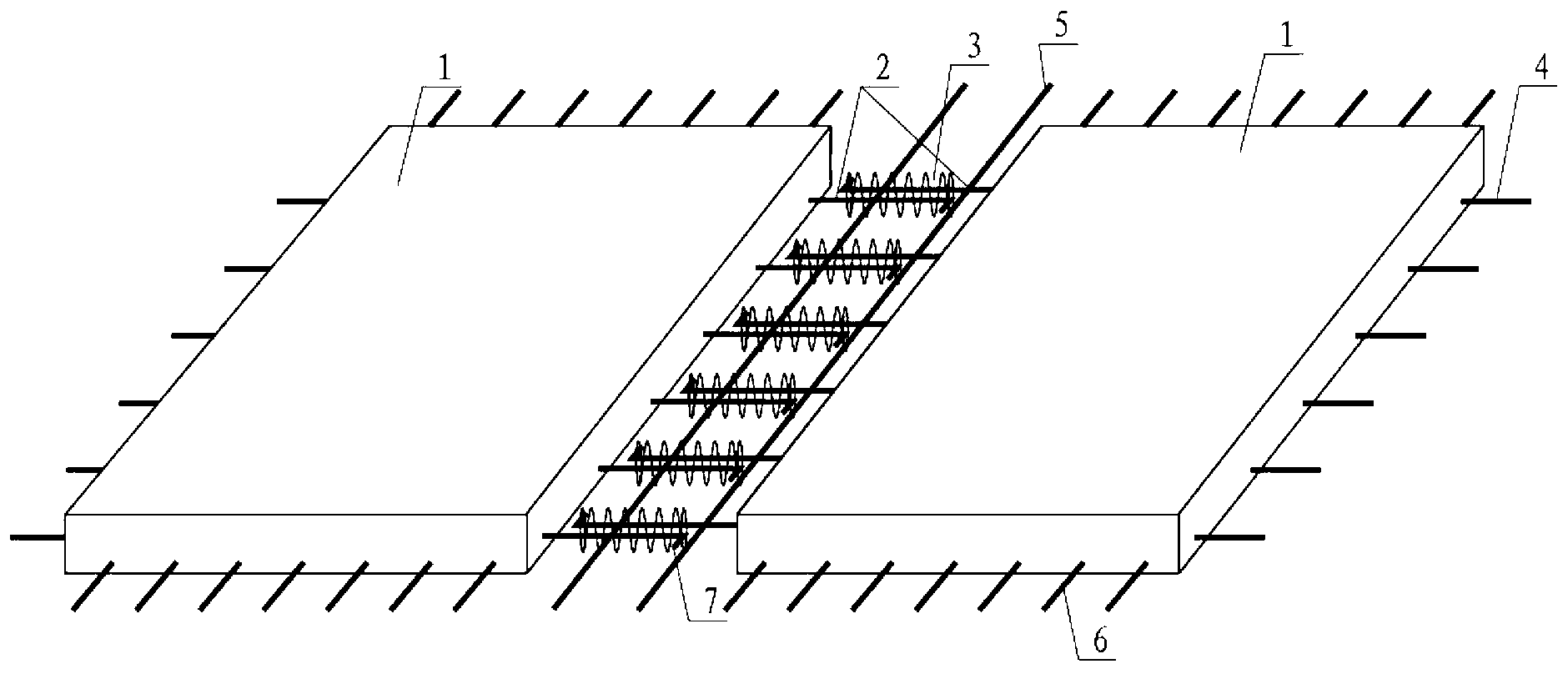

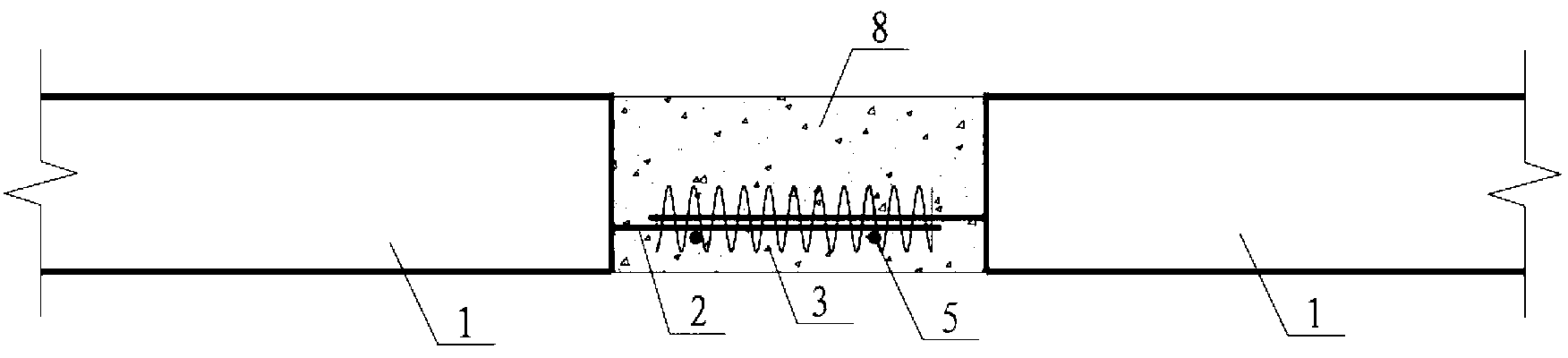

[0019] In the present invention, at the splicing connection ends of two pre-spliced floor members 1 (multiple pieces are spliced and connected in the same way), the reserved slab bottom steel bar 2 of the floor is extended to a certain length from the end of the slab, and the length range is (200-400) mm, the distance between the extended steel bars is the same as the steel bar at the bottom of the slab, which is the steel bar at the bottom of the slab (100-200) mm required by the specification, and a vertical hook 7 is provided at the end of the steel bar, and the straight section length of the hook is 10 times the diameter of the steel bar; the vertical hook 7 is arranged horizontally; the steel bar 4 at the bottom of the slab is installed in the floor member 1. When splicing and connecting the floor members 1, reserve a post-casting strip of a certain width between the pre-spliced floor members 1. The width of the post-casting strip is (200-400) mm, and the overhanging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com