Steam heating furnace

A heating furnace and steam technology, applied in the field of daily life appliances, can solve the problems of slow steaming speed, single taste, food moisture loss, etc., to achieve the effect of improving speed and efficiency, improving heat utilization rate, and retaining nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

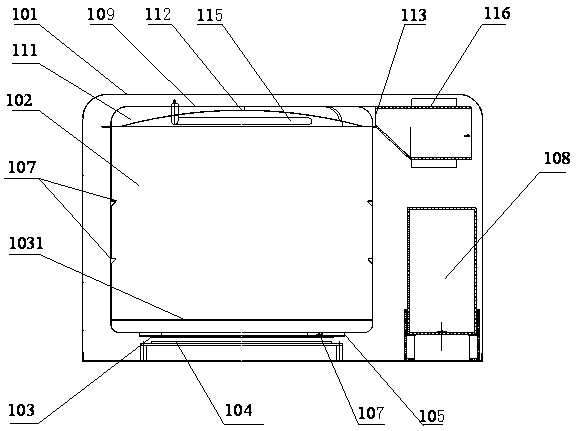

[0026] The present invention provides a steam heating furnace. In order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

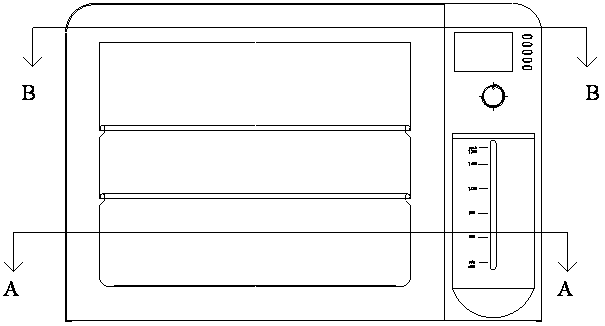

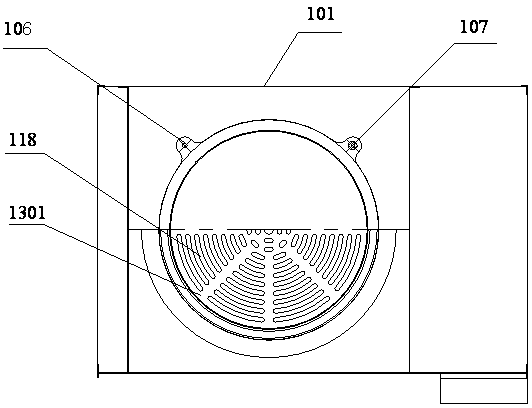

[0027] The invention provides a steam heating furnace. A heating device is arranged at the bottom of the cavity of the furnace body. The heating device can quickly and continuously generate a large amount of steam for steaming food. like figure 1 and figure 2 As shown, the steam heating furnace includes a furnace body 101, and a cavity 102 is arranged in the furnace body 101, and the furnace body 101 and the cavity 102 can be realized by any existing methods in the prior art.

[0028] The lower part of the cavity 102 is provided with a heat generating device capable of generating steam, and the food is heated by the steam generated rapidly and continuously by the heat generating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com