Auxiliary power supply system of urban rail vehicle

A vehicle auxiliary and power supply system technology, applied to vehicle components, collectors, electric vehicles, etc., can solve the problems of large load starting current, heavy weight, and large power supply volume, and achieve the effect of reducing equipment cost and vehicle weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

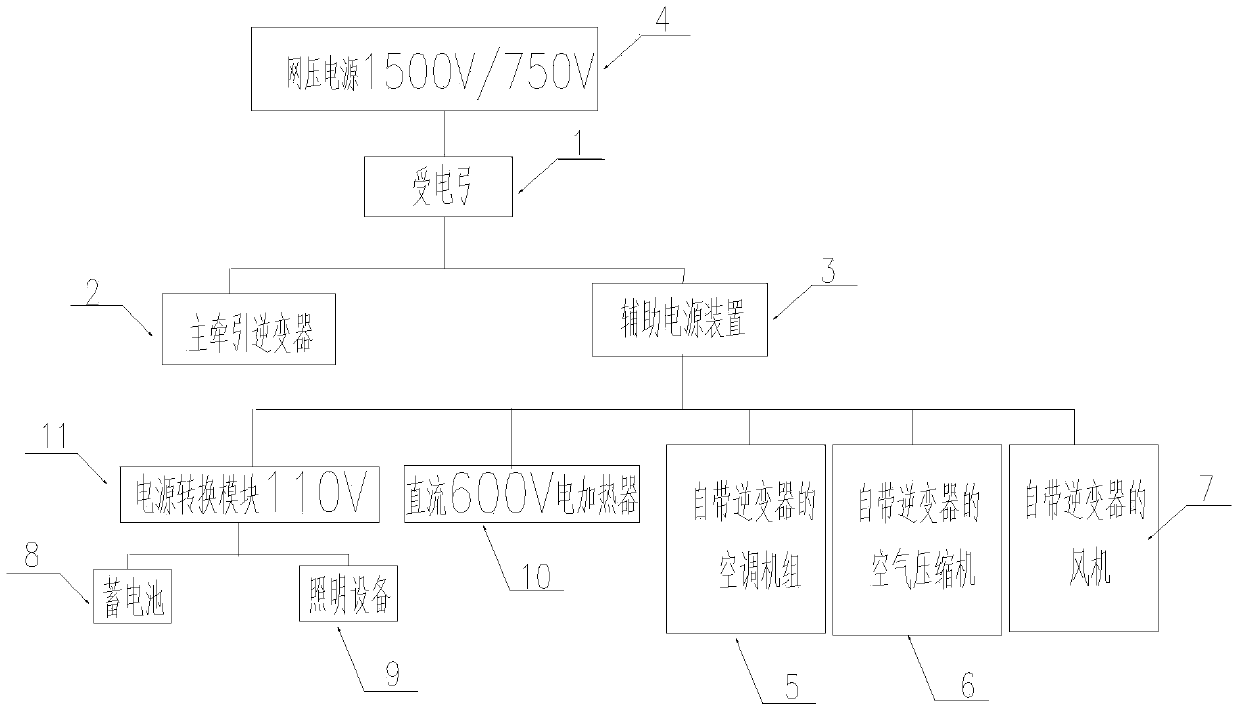

Embodiment 1

[0023] like figure 1 As shown, an auxiliary power supply system for urban rail vehicles according to the present invention includes a pantograph 1, a main traction inverter 2 and an auxiliary power supply device 3. The bow head of the pantograph 1 is in contact with the catenary 4, and the catenary The network voltage power supply of 4 is 1500V or 750V. After the current passes through the pantograph 1 and the main cable of the vehicle in sequence, the current is transmitted to the main traction inverter 2 and the auxiliary power supply device 3 .

[0024] Among them, the main traction inverter 2 converts the input 1500V or 750V direct current into three-phase alternating current and then outputs it to the traction motor connected thereto, so as to drive the traction motor and then drive the train.

[0025] The auxiliary power supply device 3 steps down the input DC power of 1500V or 750V, and then outputs a DC power supply of 400-750V. In this embodiment, the auxiliary power ...

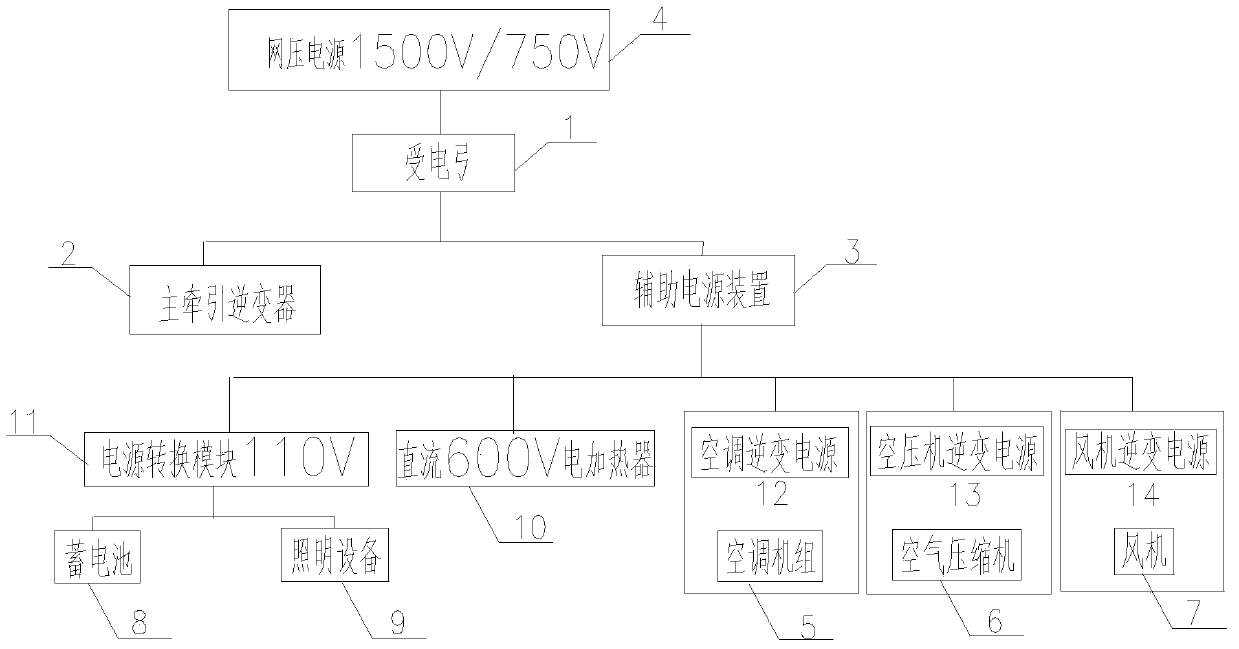

Embodiment 2

[0034] like figure 2 As shown, the difference from Embodiment 1 is that an air-conditioning inverter power supply 12 is connected at the input end of the air conditioning unit 5, an air compressor inverter power supply 13 is connected at the input end of the air compressor 6, and an air compressor inverter power supply 13 is connected at the input end of the air-conditioning unit 5. End is connected with a fan inverter power supply 14, the input end of the air conditioner inverter power supply 12, the air compressor inverter power supply 13 and the fan inverter power supply 14 is connected with the output end of the auxiliary power supply device 3, the air conditioner inverter power supply 12, the air compressor inverter power supply The inverter power supply 13 and the fan inverter power supply 14 are used to convert the 600V direct current output by the auxiliary power supply device 3 into 380V, 220V and other alternating currents required by the air conditioner unit 5, the ...

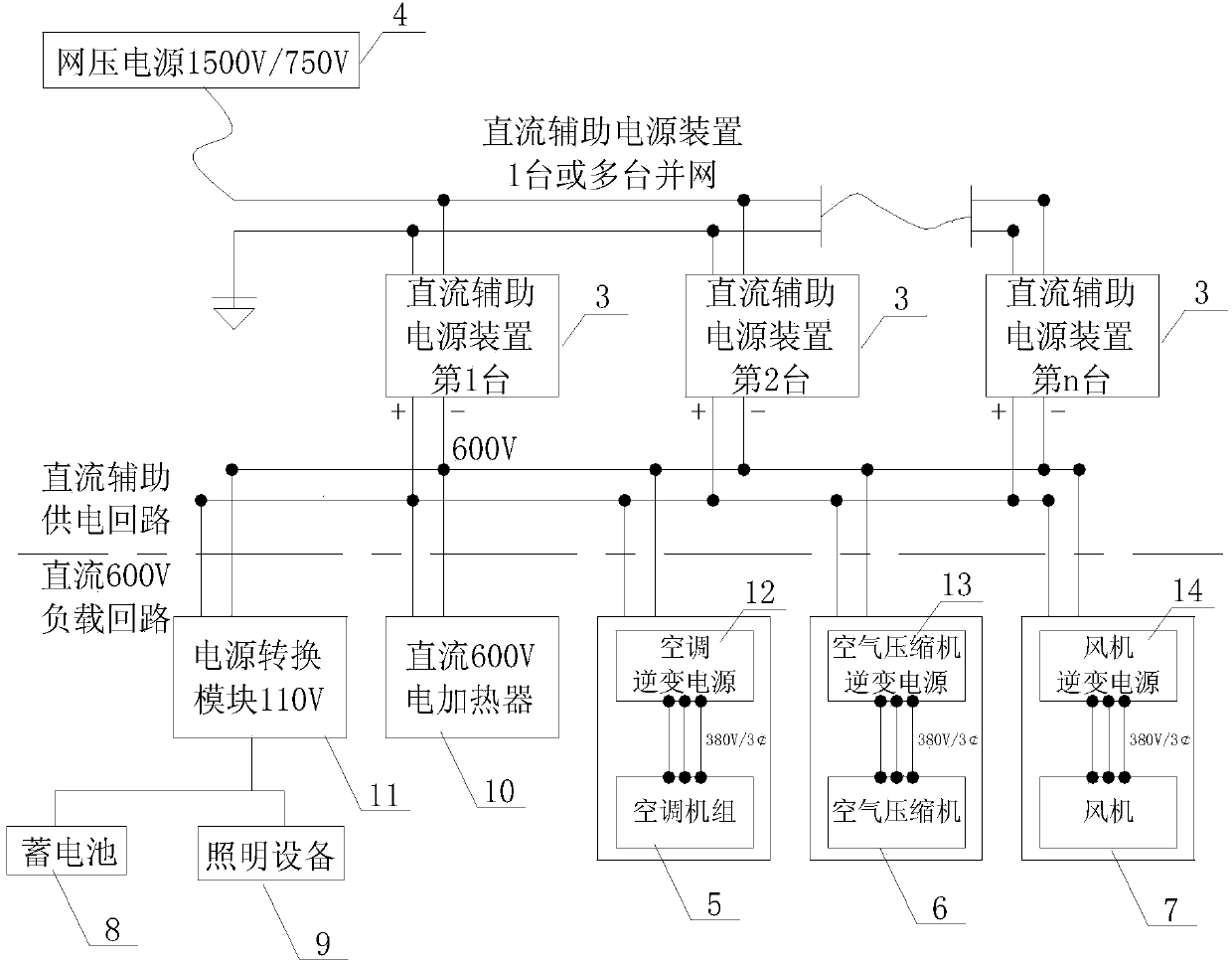

Embodiment 3

[0037] The difference from the above two embodiments is that in this embodiment, there are multiple auxiliary power supply devices 3, and the multiple auxiliary power supply devices 3 supply power to each electric load through DC grid connection, such as image 3 As shown, three auxiliary power supply devices 3 are used, which can not only ensure the power consumption of each load of the whole train, but also ensure that when one or two auxiliary power supply devices 3 fail, the other auxiliary power supply devices 3 can still guarantee required for train operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com