High-low pressure turbine transition section layout structure and design method thereof

A low-pressure turbine and layout structure technology, applied in the direction of mechanical equipment, stators, engine components, etc., can solve the problem that the performance and compactness of the transition section of the high-low pressure turbine cannot meet the actual needs, increase the flow field distortion and swirl intensity at the inlet of the low-pressure turbine, Increase the difficulty of low-pressure turbine design to achieve the effect of shortening the axial span, reducing the number of blades, and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

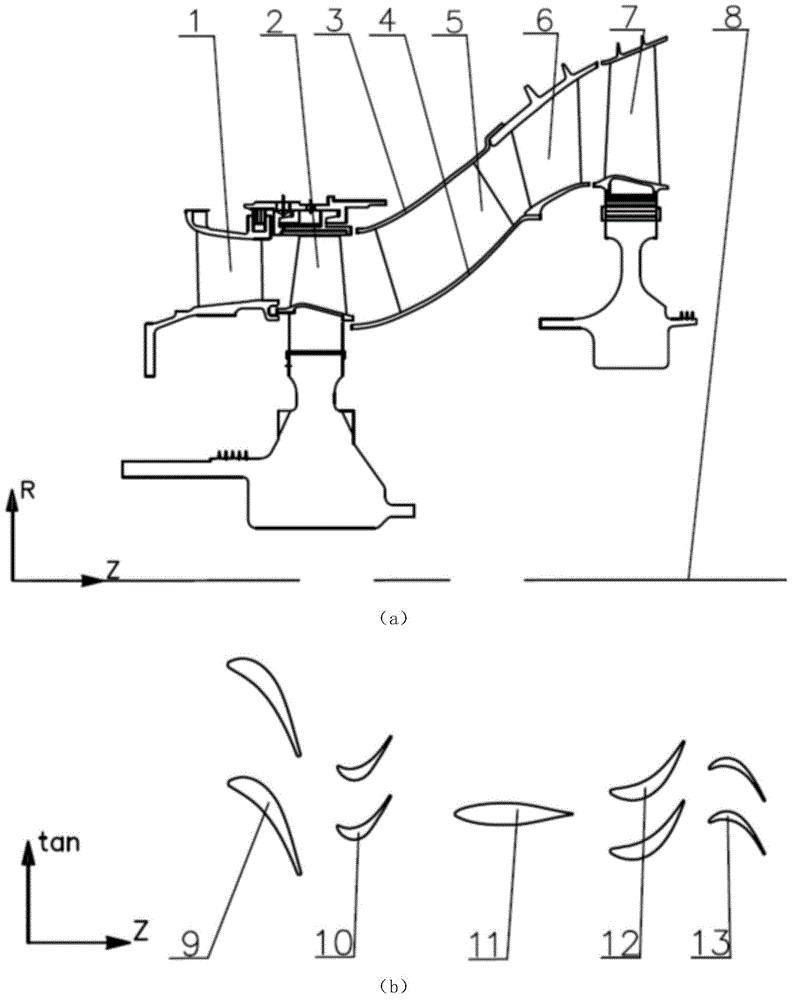

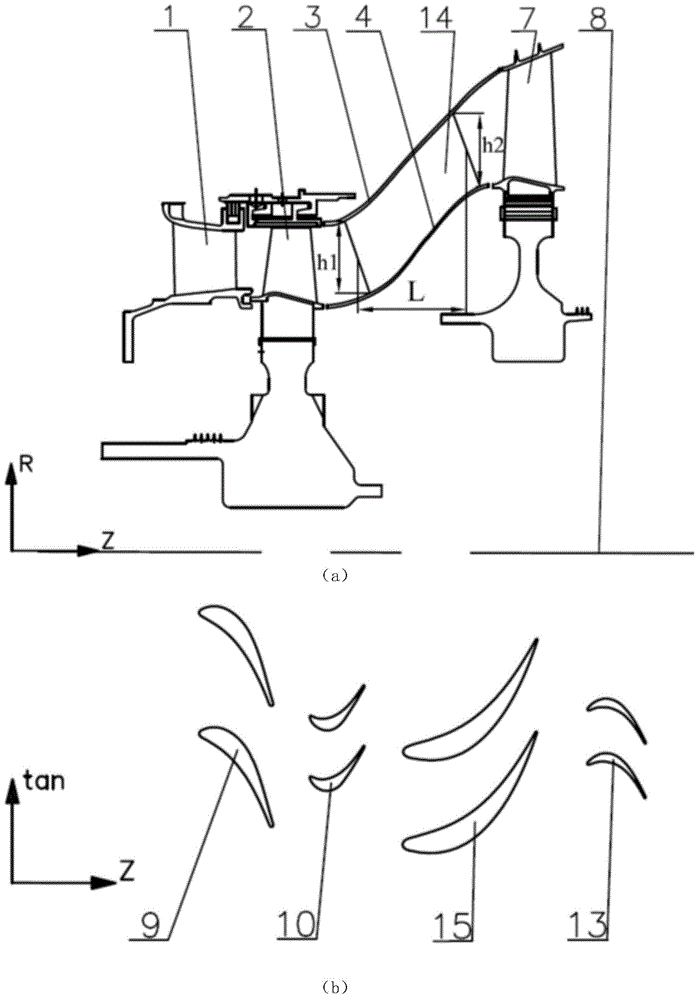

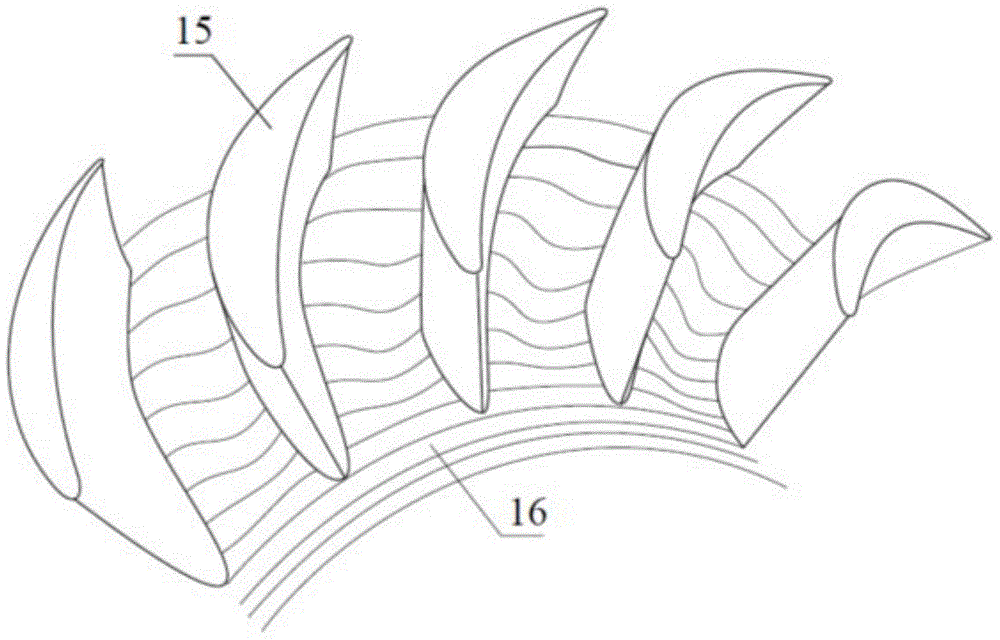

[0016] Such as figure 1 As shown, the high-pressure turbine of a typical turbofan engine and its transition section are mainly composed of a high-pressure turbine guide 1, a high-pressure turbine rotor 2, an outer end wall 3 of the transition section, an inner end wall 4 of the transition section, a support plate 5 of the transition section, and a low-pressure turbine guide 6 and low-pressure turbine rotor 7, figure 1 (b) shows the high-pressure turbine guide vane section 9, the high-pressure turbine rotor blade section 10, the strut blade section 11, the low-pressure turbine guide vane section 12, the low-pressure turbine rotor section 13, the outer end wall 3 of the transition section and the transition section The inner end wall 4 consti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com