A fuel delivery high-pressure common rail system for jet thermal combustion

A technology of fuel delivery and common rail system, which is applied in charging systems, fuel injection devices, engine components, etc., can solve the problems of difficult pressure parameter detection points, no mechanical movement links, fluctuations in injection variables, etc., to improve safety and reliability. The effect of eliminating the principle defect and reducing the pulsation amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples provided by the present invention are only for further illustrating the application of the present invention, rather than limiting.

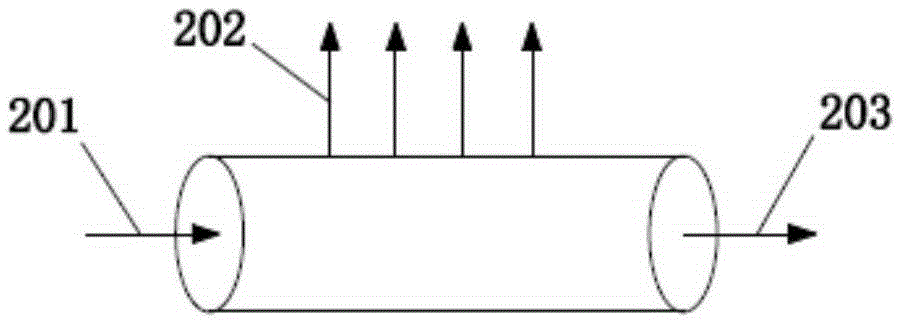

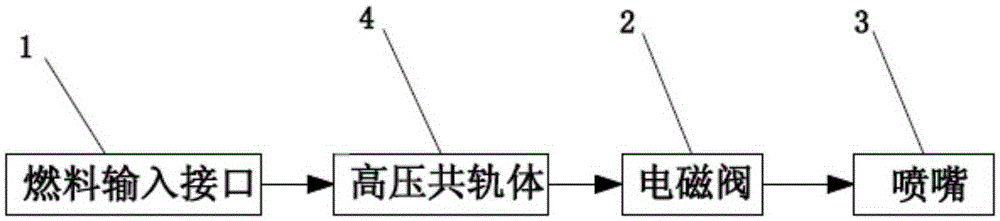

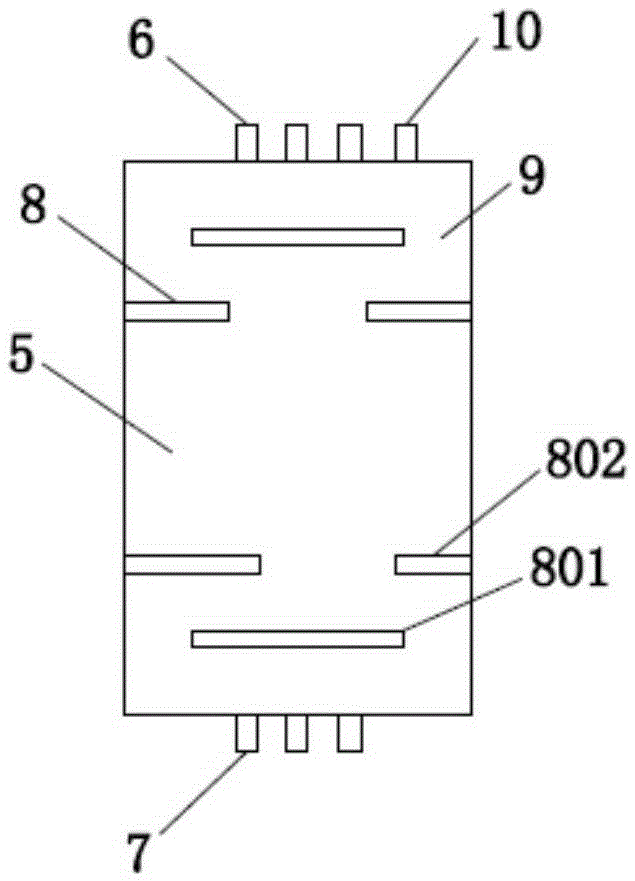

[0028] Such as figure 2 As shown, a fuel delivery high-pressure common rail system for injection thermal combustion, the common rail system includes a fuel input interface 1, a high-pressure common rail body 4, a solenoid valve 2 and a nozzle 3 connected in sequence through a fuel delivery pipe, The fuel input interface 1 can be a pump pressure delivery interface, a pneumatic medium delivery interface or a pipeline booster delivery interface, and the high-pressure common rail body 4 can be provided with multiple fuel inlets and outlets, and the multiple outlets are correspondingly provided with multiple groups of electromagnetic Valve 2 and nozzle 3, one solenoid valve 2 can be connected to one nozzle 3 correspondingly, and can also be connected to multiple nozzles 3 at the same time, part or all of the fuel outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com