Near-infrared on-line coal quality measurement device

A measuring device, near-infrared technology, is applied to the near-infrared coal quality online measurement device to monitor the coal quality composition in other related places in real time, and in the field of on-line detection of the coal quality of the power station into the furnace, which can solve the problem of affecting the measurement accuracy, endangering the human body, System error and other problems, to achieve the effect of guaranteeing accuracy, improving precision and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

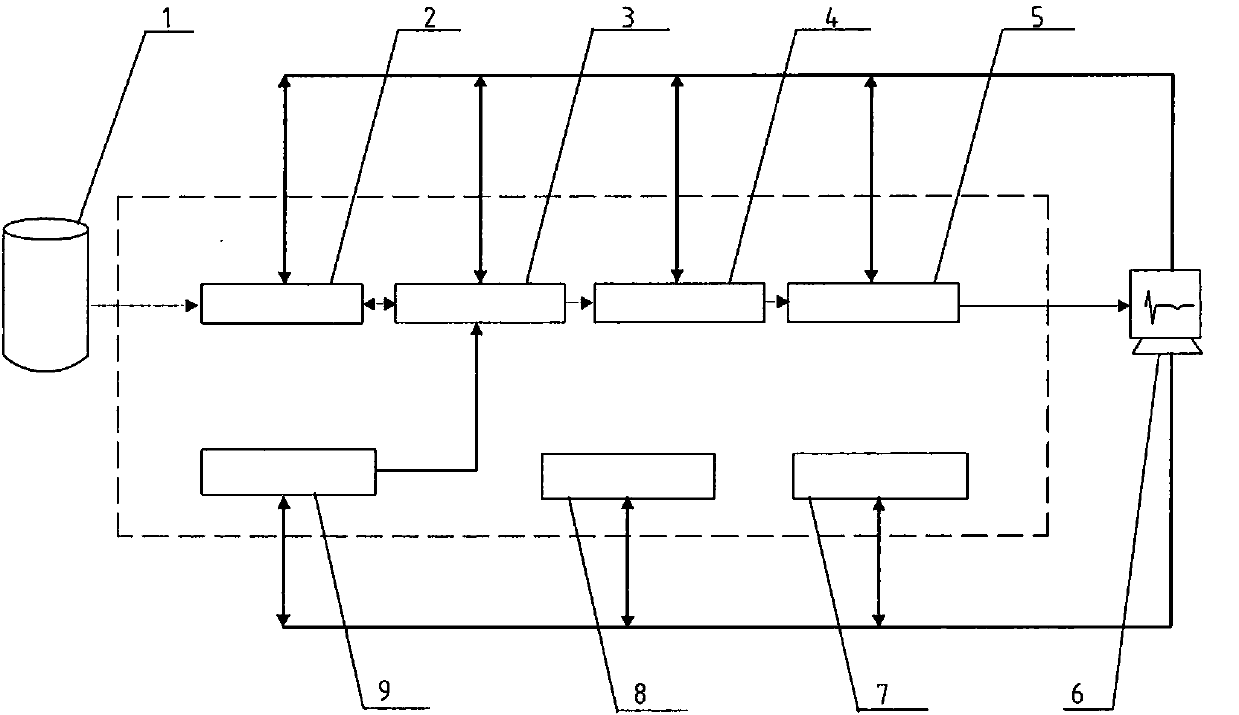

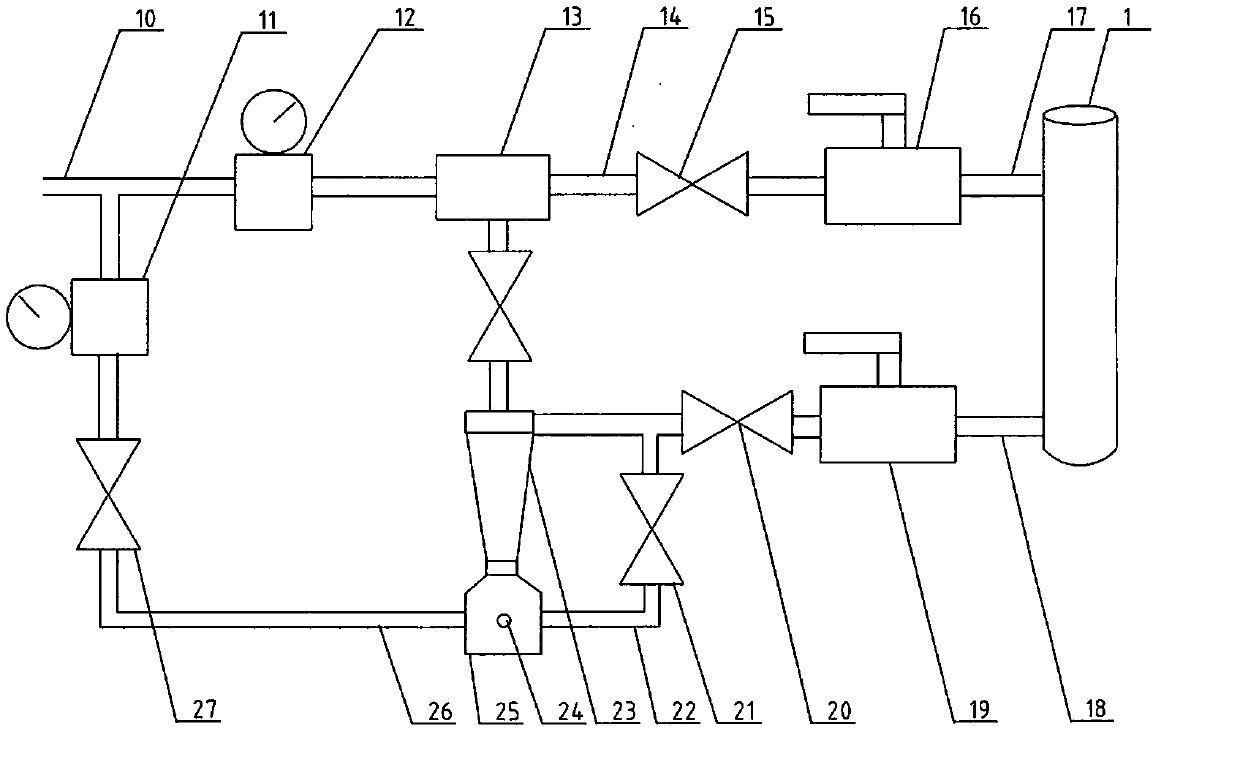

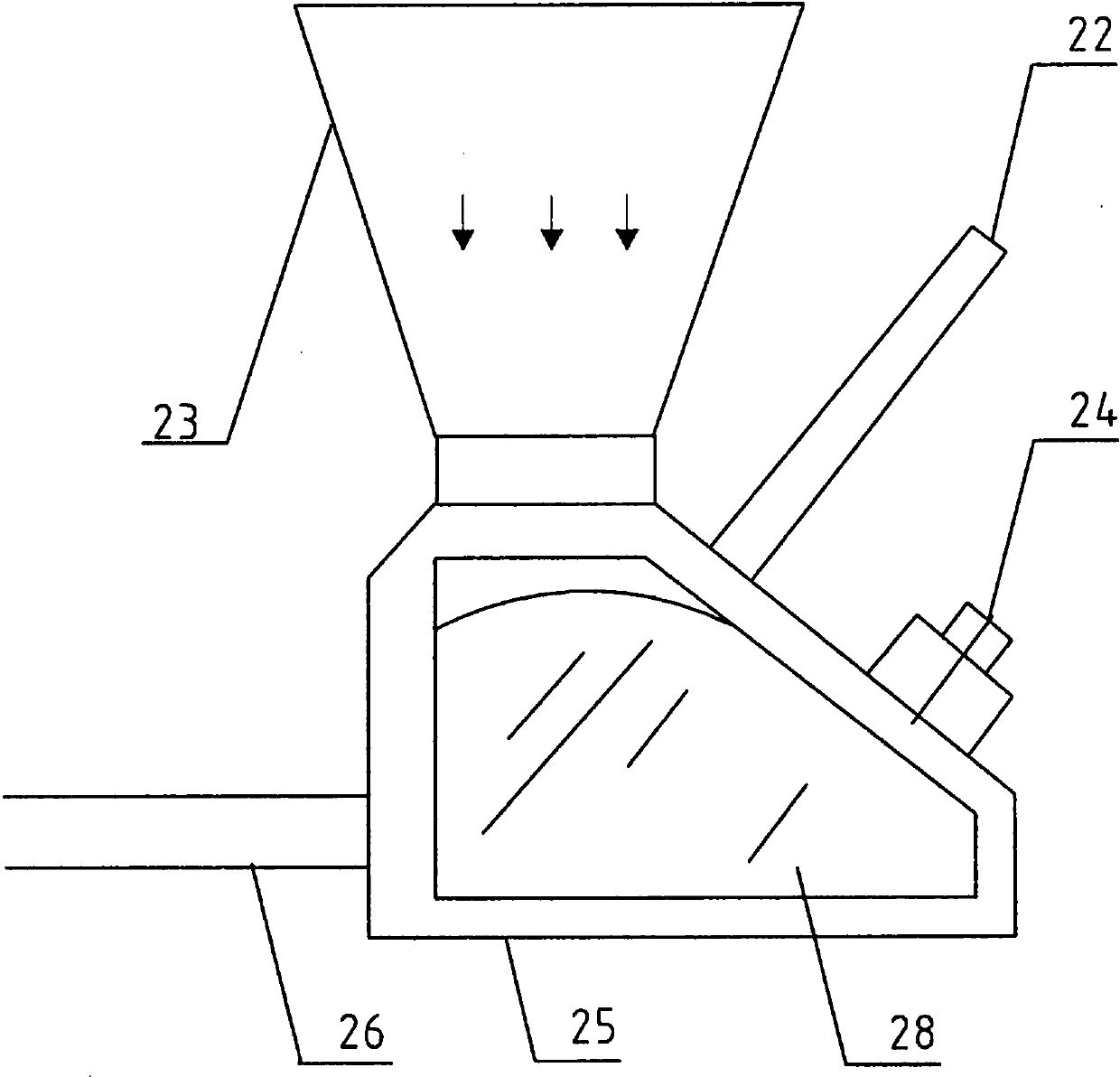

[0017] according to Figure 1~5 The specific structure and working process of the present invention will be described in detail. The near-infrared coal quality on-line measurement device includes a control cabinet, a pulverized coal sampling unit 2 connected to a pulverized coal pipeline 1 assembled in the control cabinet, a near-infrared detection unit 3, a data acquisition unit 4, a data analysis and processing unit and a near-infrared The generating unit 9, and the remote main control computer 6 and other components connected to each unit through the control loop formed by the transmission line. Among them, the control cabinet adopts a sealed cabinet with a built-in automatic temperature control unit composed of a temperature sensor 7 and a refrigeration unit 8 ( figure 1 shown in the dotted box). The role of the sealed cabinet in the coal quality calculation process is mainly to monitor the temperature sensor 7 in the sealed cabinet through the remote main control comput...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com