Online detection method for scrap iron content in pivoting support lubricating grease and lubricating grease online detection device

A technology of slewing bearing and detection device, which is applied in the field of on-line detection device for lubricating grease and on-line detection of iron filings content in slewing bearing grease, which can solve the problems of real-time detection limitation, long analysis period, slow response speed, etc., and achieve good application Promoting value, avoiding long analysis cycles, and improving the effect of lubrication conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

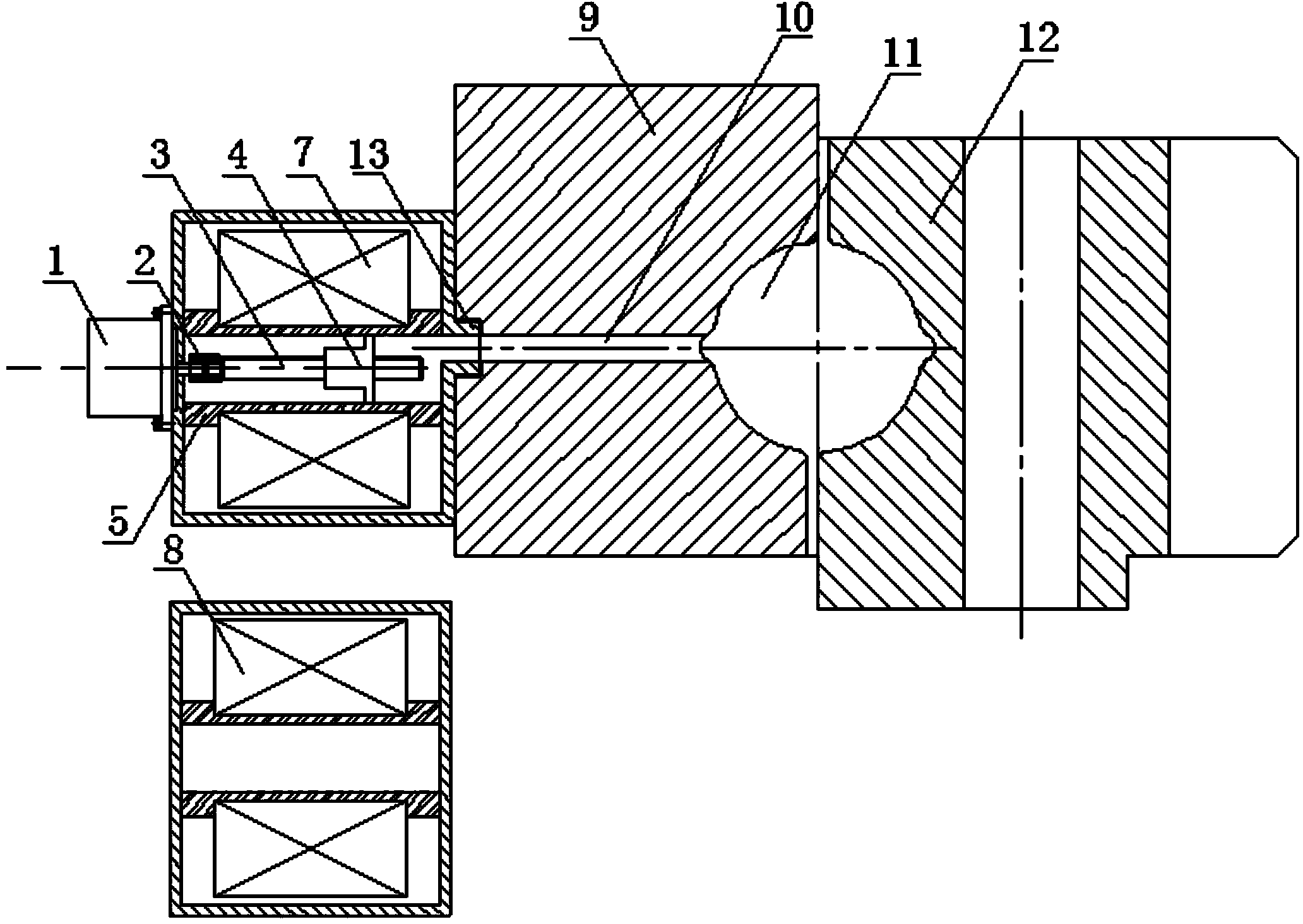

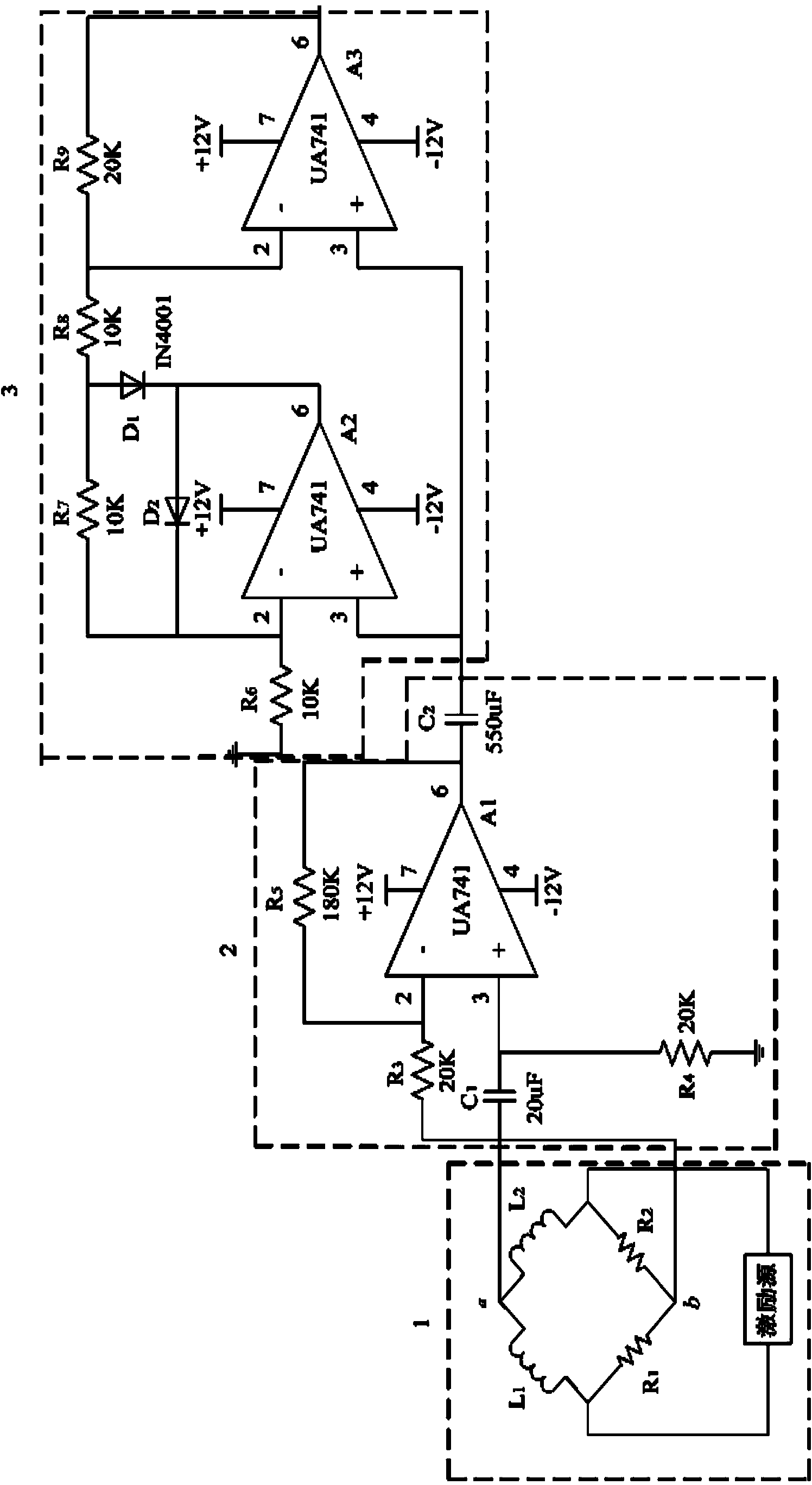

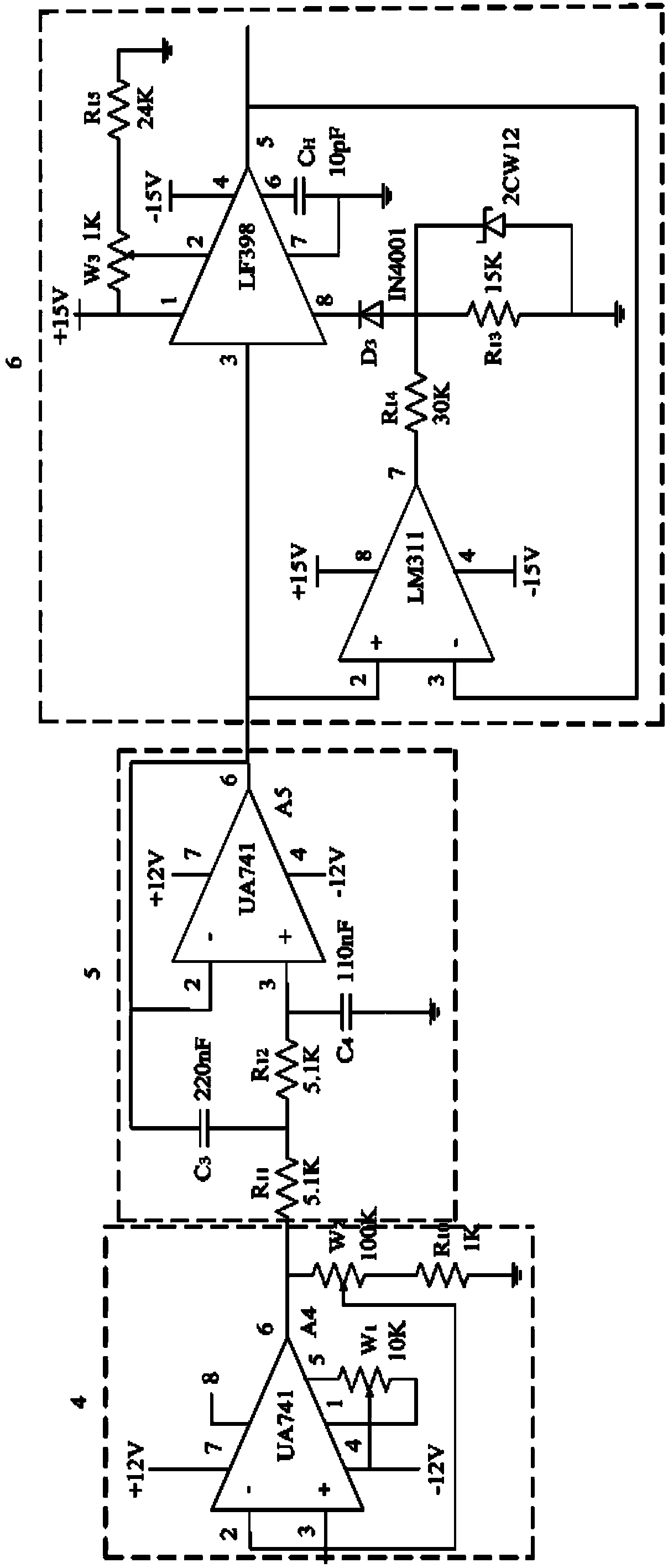

[0021] The present invention will be further described below in conjunction with the drawings.

[0022] An online detection method of iron filings content in slewing bearing grease, characterized in that: the method uses the grease online detection device of claim 3 to realize automatic sampling of grease, and coil inductance is caused by iron filings in the sampled grease. The amount change is used to determine the content of iron filings in the grease. The greater the change in inductance, the more iron filings in the grease, which can effectively determine the degree of wear in the raceway during the operation of the slewing ring.

[0023] The method also includes comparing the real-time detected inductance difference with the set warning value to determine whether the grease is invalid: when the real-time detected inductance difference is less than the set warning value, the starter motor 1 sends the grease back through the channel 10 In the slewing bearing, the opposite means ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com