Particulate fouling experimental device, prediction method and prediction system for arc-tube heat exchanger

A technology of prediction system and experimental device, applied in the field of particle fouling experimental device and prediction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The method and system for predicting particle fouling characteristics of the arc tube heat exchanger will be further described below in conjunction with the accompanying drawings and embodiments.

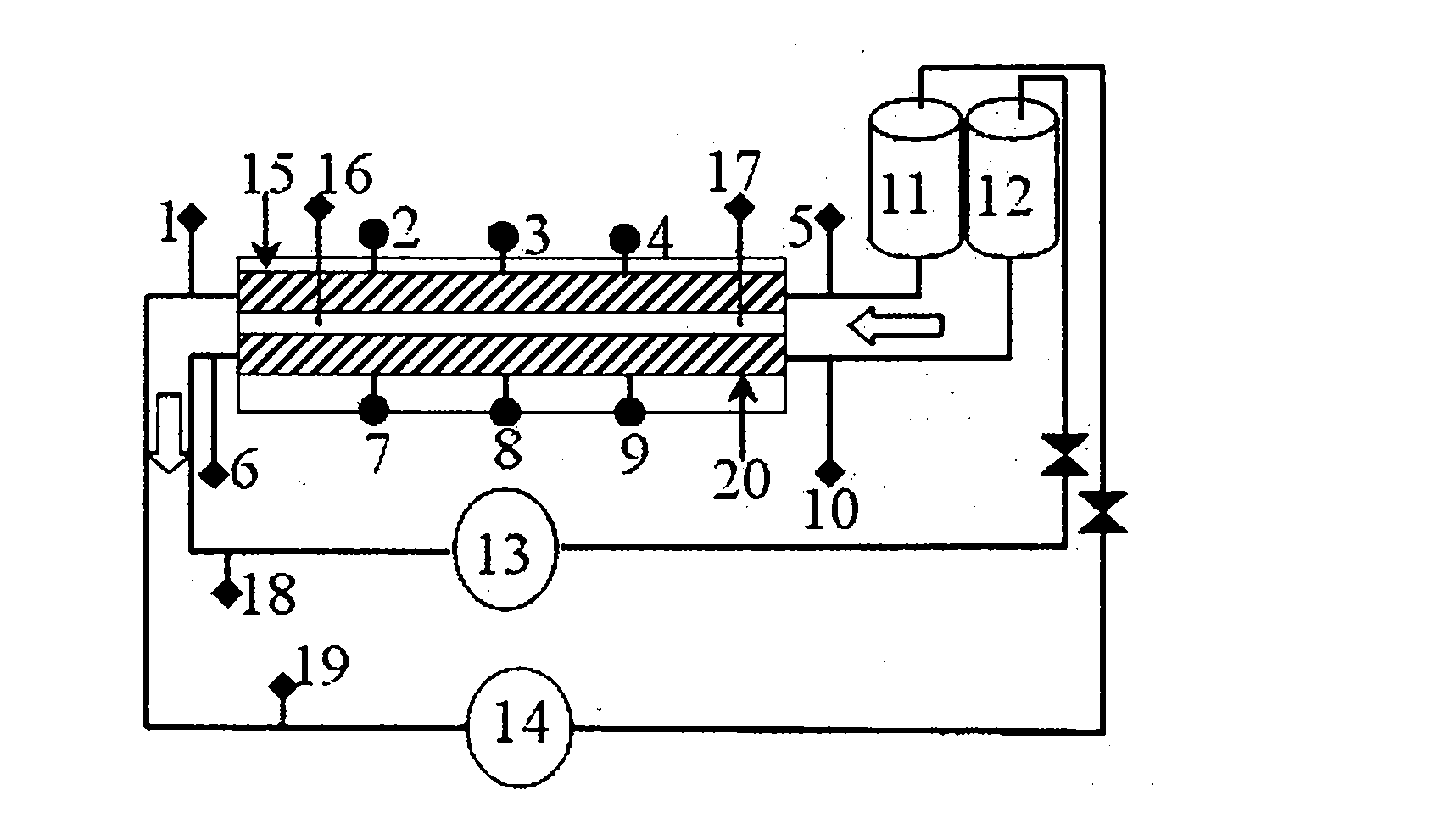

[0069] Such as figure 1 As shown, during the test, for comparison, two identical stainless steel arc tubes (15, 20) were used as experimental tubes. Wherein, pipe A (15) and pipe B (20) are set to different flow rates, but the particle concentration is the same. During the experiment, parameters were collected every 5 minutes and recorded in the database. Then all the outlet temperature (1, 6), inlet temperature (5, 10), water bath temperature (16, 17) and dirt thermal resistance measurement values collected within 1 hour are averaged and stored in the database again, thus the two 280 sets of data were obtained for each experimental tube, 80 of which were used as training samples, and the rest were used as test samples.

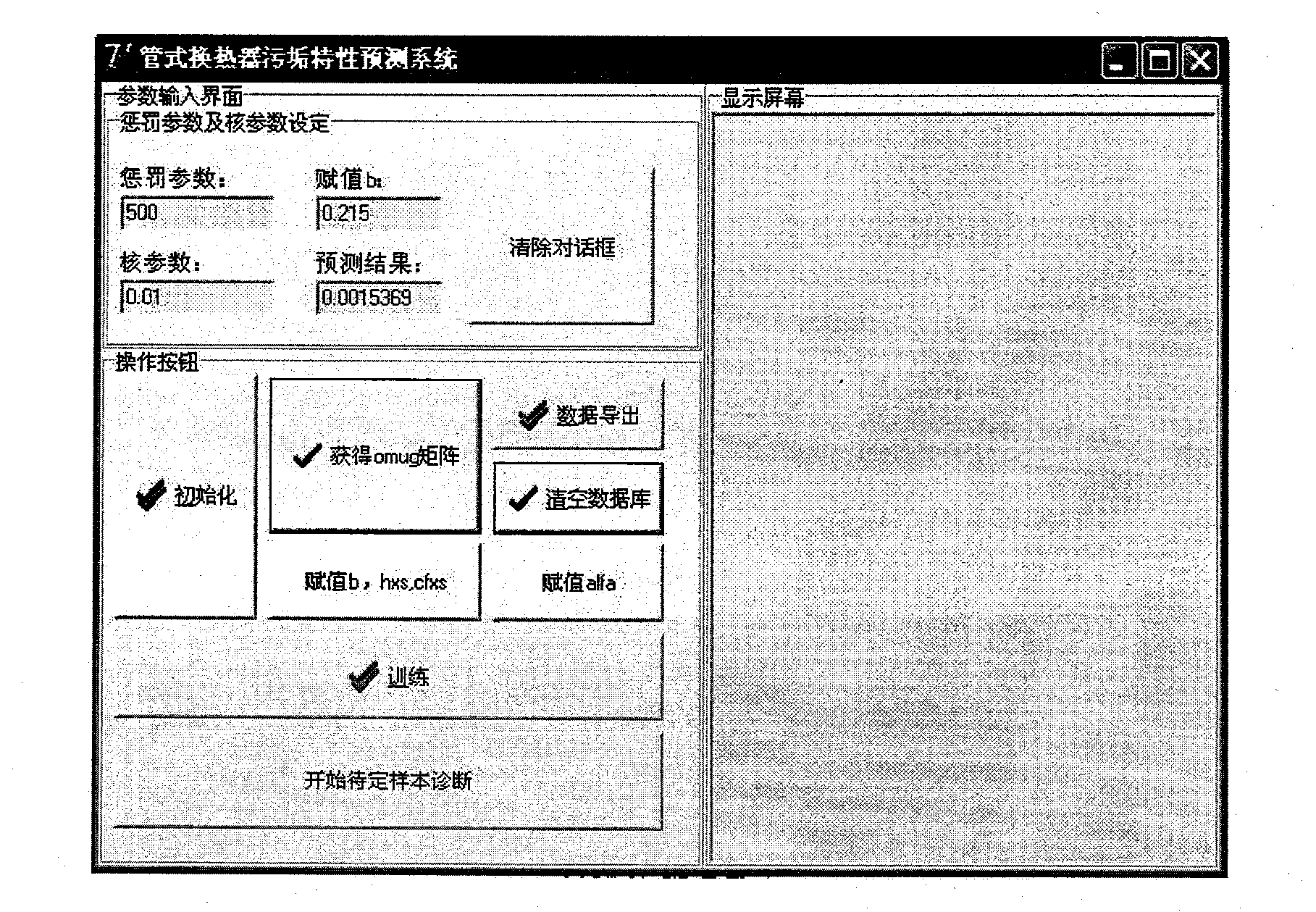

[0070] A prediction model was established based o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com