A black tea fermentation process and a special fermenter for black tea fermentation

A fermentation process and fermenter technology, which is applied in the field of black tea fermentation process and special fermenter for black tea fermentation, which can solve the problems of lack of bright red soup, uneven quality of tea leaves, uneven fermentation of tea leaves, etc., to achieve fresh taste and bright red soup color , the effect of uniform tea quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Black tea fermentation process step of the present invention is as follows:

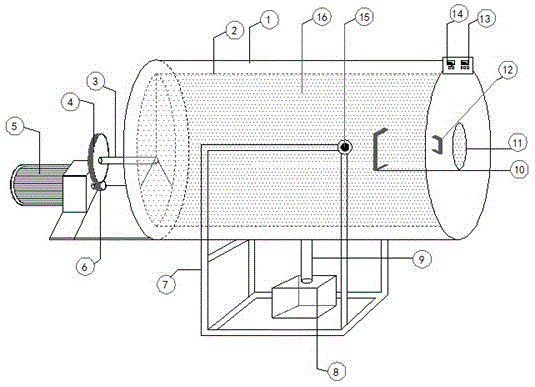

[0032] Put 100kg of withered and moderately rolled black tea greens into a fermenter placed horizontally, and gently rotate the black tea in the fermenter at a frequency of 1 revolution / 2min to ensure the temperature, humidity and oxygen contact of tea inside and outside the pile. The probability of all the same, while rotating, adjust the temperature: within the temperature range of 30°C to 20°C, successively decrease and change the temperature to ferment, the specific variation law of the temperature in the fermentation process is shown in Table 1, and the black tea of the present invention is obtained after the fermentation is completed.

[0033] Table 1

[0034] .

[0035] The black tea obtained by applying the above method is evenly fermented, and the quality of the same batch of tea leaves is uniform. Compared with the control sample fermented at constant temperature for 150 minutes...

Embodiment 2

[0045] Black tea fermentation process step of the present invention is as follows:

[0046] Put 100kg of withered and moderately rolled black tea greens into a horizontally placed fermenter, and gently rotate the black tea in the fermenter at a frequency of 1 revolution / 1min to ensure that the temperature, humidity and oxygen contact between the inside and outside of the tea pile The probability of the temperature is the same, while rotating, adjust the temperature: in the temperature range of 30°C to 20°C, successively decrease and change the temperature to ferment, the specific variation law of the temperature in the fermentation process is shown in Table 3, and the black tea of the present invention is obtained after the fermentation is completed.

[0047] table 3

[0048] .

Embodiment 3

[0050] Black tea fermentation process step of the present invention is as follows:

[0051] Put 100kg of withered and moderately rolled black tea greens into a horizontally placed fermenter, and gently rotate the black tea in the fermenter at a frequency of 1 revolution / 5min to ensure that the temperature, humidity and oxygen contact of the tea leaves inside and outside the pile The probability of all the same, while rotating, adjust the temperature: within the temperature range of 30 ℃ to 20 ℃, successively decrease and change temperature fermentation, the specific variation law of temperature in the fermentation process is shown in Table 4, and the black tea of the present invention is obtained after the fermentation is completed.

[0052] Table 4

[0053] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com