Method for Brazing Amorphous Alloy Using au-12ge Eutectic Solder

An amorphous alloy and brazing technology, which is applied in the field of material welding, can solve the problems of poor wettability of amorphous alloys, and achieve the effects of improving mechanical properties, avoiding adverse effects, and controlling temperature accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

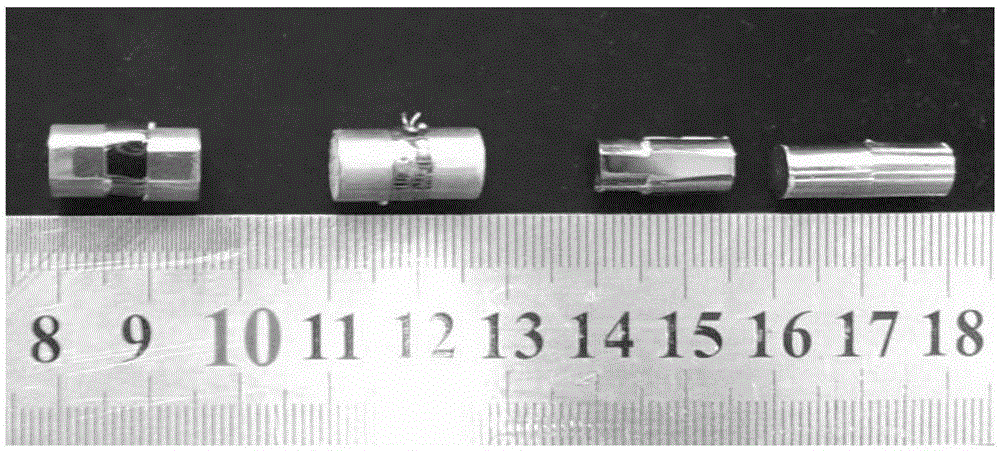

[0024] This embodiment is a method for brazing Zr-based amorphous alloy rods and red copper rods using Au-Ge eutectic solder, and the Zr-based amorphous alloy is a Zr-based amorphous alloy with a diameter of 8mm 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 The amorphous alloy rod, the Au-Ge eutectic solder is eutectic foil ribbon solder, the thickness of the eutectic foil ribbon solder is 80 μm; the diameter of the copper rod is 8mm.

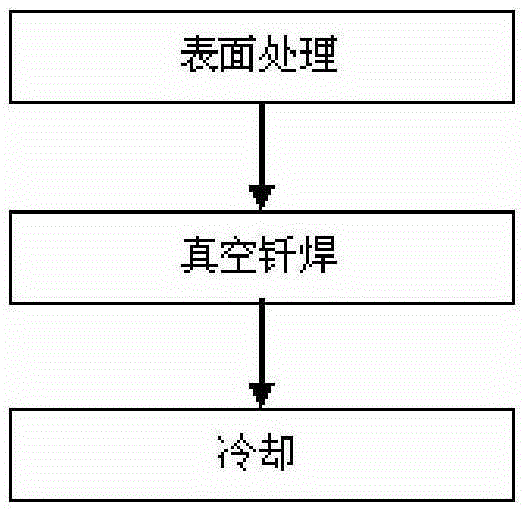

[0025] The concrete process of this embodiment is:

[0026] Step 1, surface treatment: Zr 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 The surfaces to be connected of the amorphous alloy and the red copper are polished with 800# or 1000# SiC sandpaper, both of which are polished with 800# SiC sandpaper in this embodiment. Put the copper rod into 10% hydrochloric acid alcohol solution for pickling for 2 minutes to fully remove the oxide layer and passivation layer on the metal surface. Au-12Ge foil eutectic solder was polished with 1500# sandpaper to remov...

Embodiment 2

[0032] This embodiment is a method for brazing Zr-based amorphous alloy rods and red copper rods using Au-Ge eutectic solder, and the Zr-based amorphous alloy is a Zr-based amorphous alloy with a diameter of 8mm 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 The amorphous alloy rod, the Au-Ge eutectic solder is eutectic foil ribbon solder, the thickness of the eutectic foil ribbon solder is 80 μm; the diameter of the copper rod is 8mm.

[0033] The concrete process of this embodiment is:

[0034] Step 1, surface treatment: Zr 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 The surfaces to be connected of the amorphous alloy and the red copper are polished with 800# or 1000# SiC sandpaper, and both are polished with 1000# SiC sandpaper in this embodiment. Put the copper rod into 10% hydrochloric acid alcohol solution for pickling for 2 minutes to fully remove the oxide layer and passivation layer on the metal surface. The Au-12Ge foil eutectic solder was polished with 1500# sandpaper to remov...

Embodiment 3

[0040] This embodiment is a method for brazing a homogeneous Zr-based amorphous alloy using Au-Ge eutectic solder, and the Zr-based amorphous alloy is a Zr-based amorphous alloy with a diameter of 6mm. 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 The bar material, the Au-Ge eutectic solder is the eutectic foil ribbon solder, and the thickness of the eutectic foil ribbon solder is 80 μm.

[0041] The concrete process of this embodiment is:

[0042] Step 1, surface treatment: Zr 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 The surface of the amorphous alloy to be connected is polished with 800# or 1000# SiC sandpaper, and 800# SiC sandpaper is used for polishing in this embodiment. The Au-12Ge foil eutectic solder was polished with 1500# sandpaper to remove the surface oxide layer. Zr 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 Amorphous alloy and Au-12Ge eutectic solder were ultrasonically cleaned in acetone solution for 5 min after the surface treatment process to remove surface pollutants....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com