Snake-like robot with the ability to adapt to uneven ground

A snake-like robot and ground technology, applied in the direction of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problem of inability to effectively control and adjust the contact force between the wheels and the ground, increase the complexity of snake-like robots, and the cost of development and maintenance. Computing power puts forward high requirements and other issues, to achieve the effect of improved contact mode, compact structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

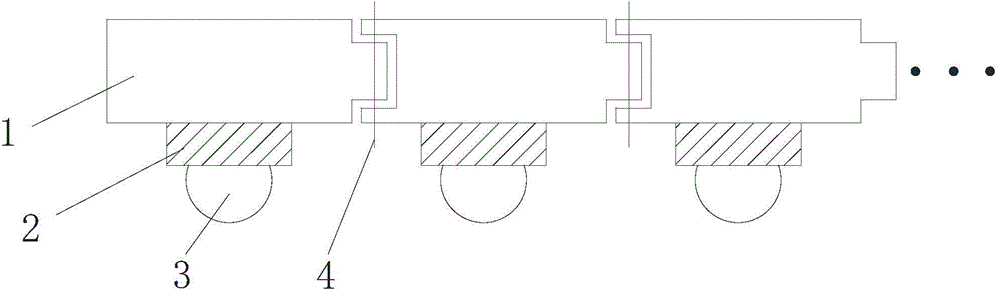

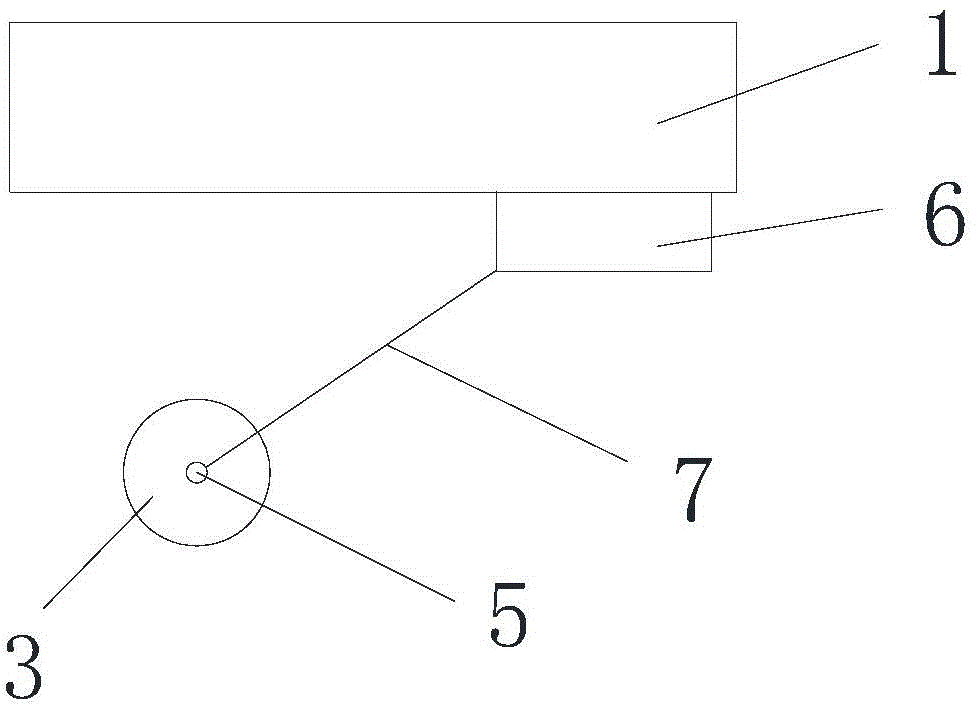

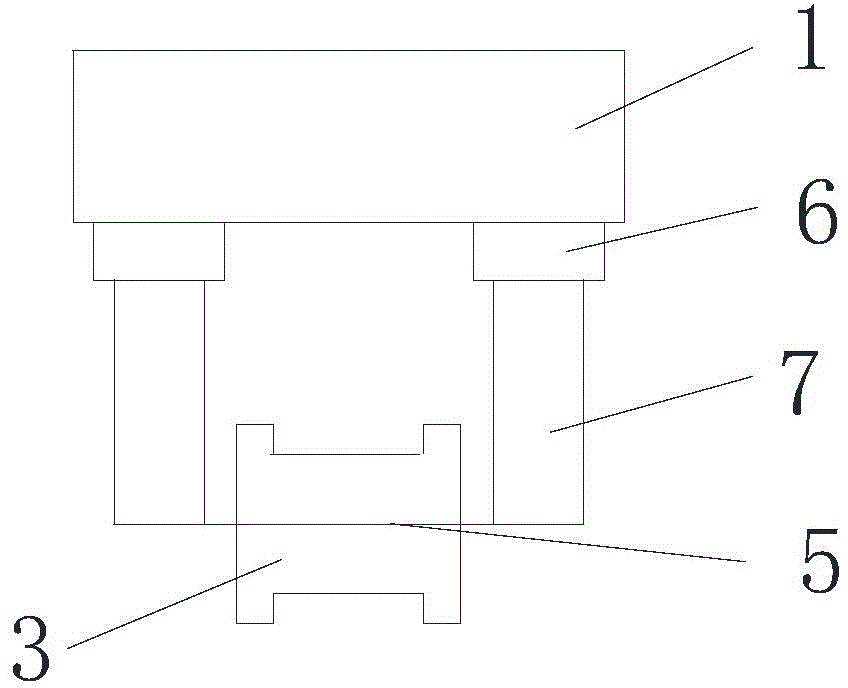

[0025] Embodiment one: if Figure 1 to Figure 3 As shown, the snake-shaped robot with the ability to adapt to uneven ground includes a snake head and a plurality of joint modules connected end to end in sequence. Wheels 3 and an adaptive suspension system 2 used to detect the contact between the wheels 3 and the ground. The wheels 3 are set on the axle 5 parallel to the fuselage 1. There are two sets of adaptive suspension systems 2 on each joint module. Located on both sides of the wheel 3 respectively, the adaptive suspension system 2 includes a force sensor 6 and a leaf spring 7, the force sensor 6 is installed at the bottom of the fuselage 1, one end of the leaf spring 7 is fixedly connected with the force sensor 6, and the other end It is fixedly connected with the wheel shaft 5; two adjacent joint modules are connected through the joint shaft 4, each joint shaft 4 is driven by the joint motor installed on each joint module, and each joint module is also equipped with a j...

Embodiment 2

[0026] Embodiment two: if Figure 4 and Figure 5 As shown, the structure of the snake robot with the ability to adapt to uneven ground is basically the same as that of the snake robot in Embodiment 1, the difference is that the adaptive suspension system 2 includes an angle sensor 9 and a leaf spring 7, One side of the bottom end of the fuselage 1 is provided with a positioning block 8 for installing the angle sensor 9, the angle sensor 9 is fixedly connected with the positioning block 8, one end of the leaf spring 7 is rotationally connected with the angle sensor 9, and the other end is fixedly connected with the wheel shaft 5 .

Embodiment 3

[0027] Embodiment three: as Image 6 As shown, the structure of the snake robot with the ability to adapt to uneven ground is basically the same as that of the snake robot in Embodiment 1, the difference is that the adaptive suspension system 2 includes a displacement sensor 10 and a leaf spring 7, The bottom front side of the fuselage 1 is provided with a first bump 12 for installing the displacement sensor 10, and the bottom rear side of the fuselage 1 is provided with a second bump 13 for installing the leaf spring 7. The bump 12 is fixedly connected, one end of the plate spring 7 is fixedly connected with the second bump 13, and the other end is fixedly connected with the wheel shaft 5, and the displacement sensor 10 is connected with the wheel shaft 5 through a vertical guide rod 11, and one end of the vertical guide rod 11 is along the The displacement sensor 10 moves up and down, and the other end is fixedly connected with the connecting end of the leaf spring 7 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com