Middle-low frequency sound insulation and heat insulation composite wall plate

A sound insulation and wall panel technology, applied in the field of medium and low frequency sound insulation and heat insulation composite wall panels, can solve the problems of inability to isolate medium and low frequencies, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

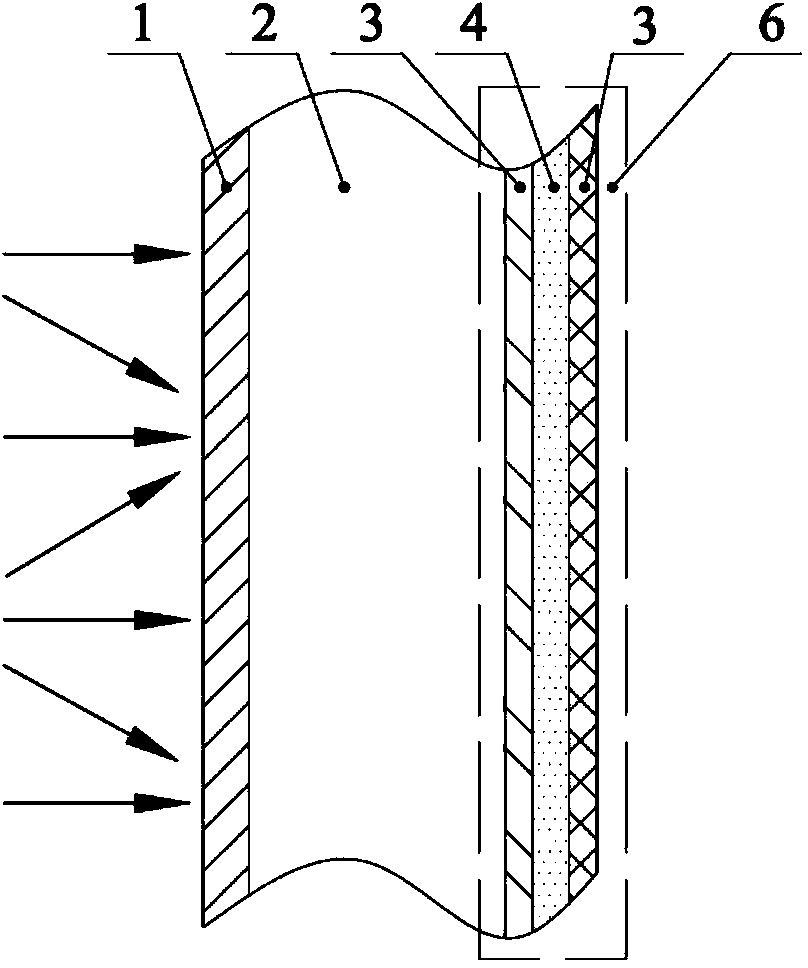

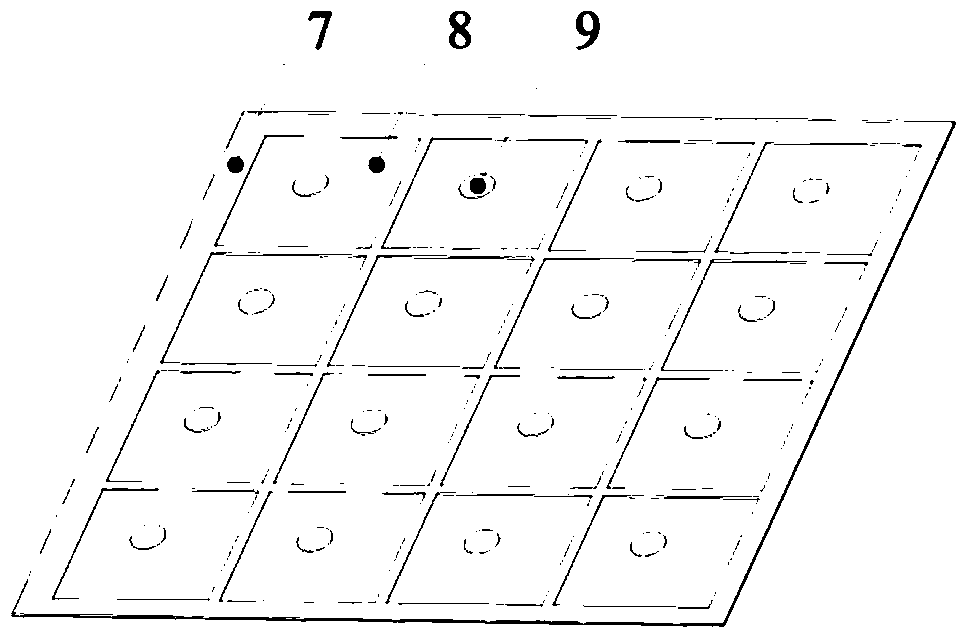

[0038] image 3 It is the first embodiment of the present invention, specifically a kind of medium and low frequency sound insulation wallboard for aircraft cabins, as shown in the figure, the shell 1 of the commercial aircraft cabin wallboard in this embodiment is aluminum alloy, with a thickness of 1.2mm -2.2mm; the heat-insulating and sound-absorbing layer 2 is made of glass fiber cotton, with a thickness between 25mm-50mm; the interior decorative board 14 is made of phenolic resin. In order to increase the space capacity in the cabin, it is desirable to make the thickness of the bulkhead plate 100mm, which makes sound insulation more difficult.

[0039] The noise outside the cabin is the main source of the noise in the cabin during the cruising phase of the aircraft. Since the sound insulation of the shell is determined, it is difficult to find a substitute with better sound insulation performance and meeting the corresponding strength and density requirements; In additio...

Embodiment 2

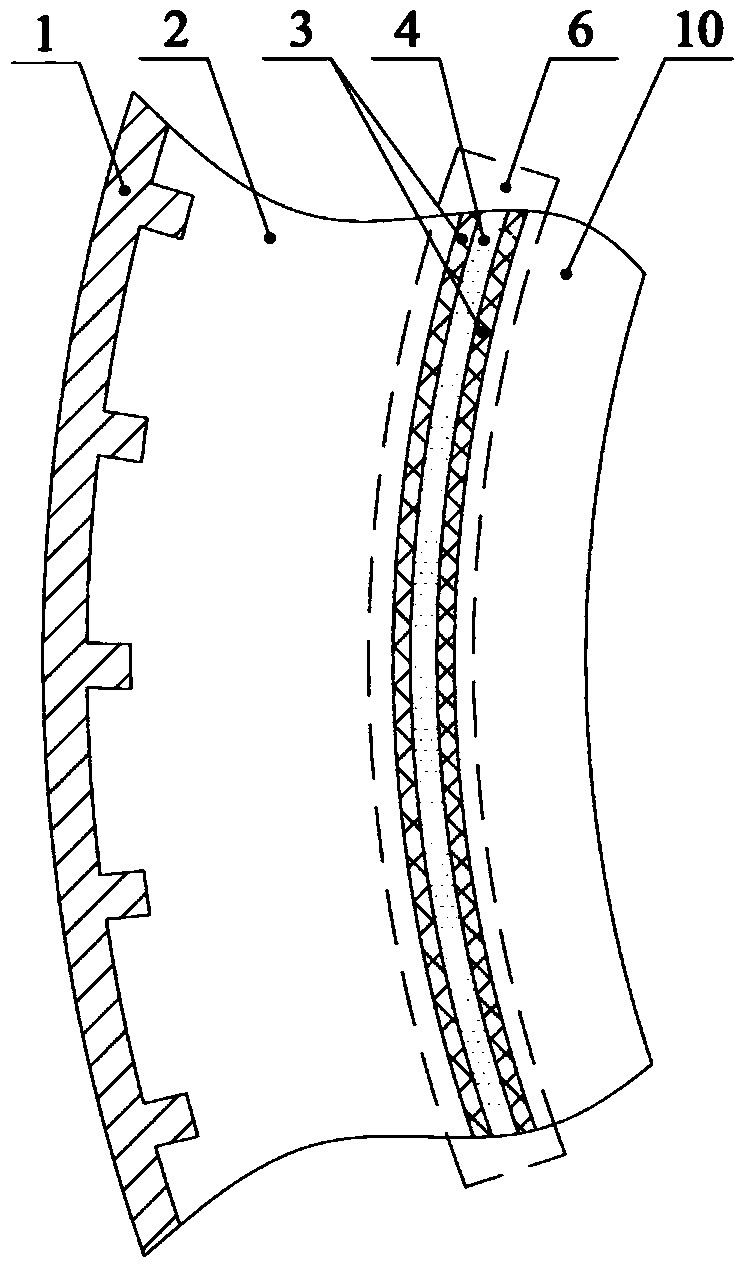

[0053] Figure 5 It is the second embodiment of the present invention, as shown in the figure, a kind of middle and low frequency sound insulation and heat insulation composite wall panel, which is characterized in that it consists of a shell 1, a heat insulation and sound absorption layer 2 and a composite panel 6 connected sequentially from outside to inside ; The composite plate 6 is composed of two first coupling vibration plates 3 and the first sound-absorbing material 4 between them. Two additional groups are provided on the inner side of the combined plate 6 , and the added groups are the second sound-absorbing material 11 and the second coupling vibration plate 12 from outside to inside.

[0054] In this embodiment, both the first coupling vibration plate and the second coupling vibration plate are made of LRPM material, and of course other materials that generate near-field waves may also be used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com