Fodder feeding cart

A feed and cart technology, applied in containers, packaging, transportation and packaging, etc., can solve the problems of inconvenient mixing, placing and use, limited application scope, low degree of automation, etc., and achieve low production cost, convenient use, and diverse use methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

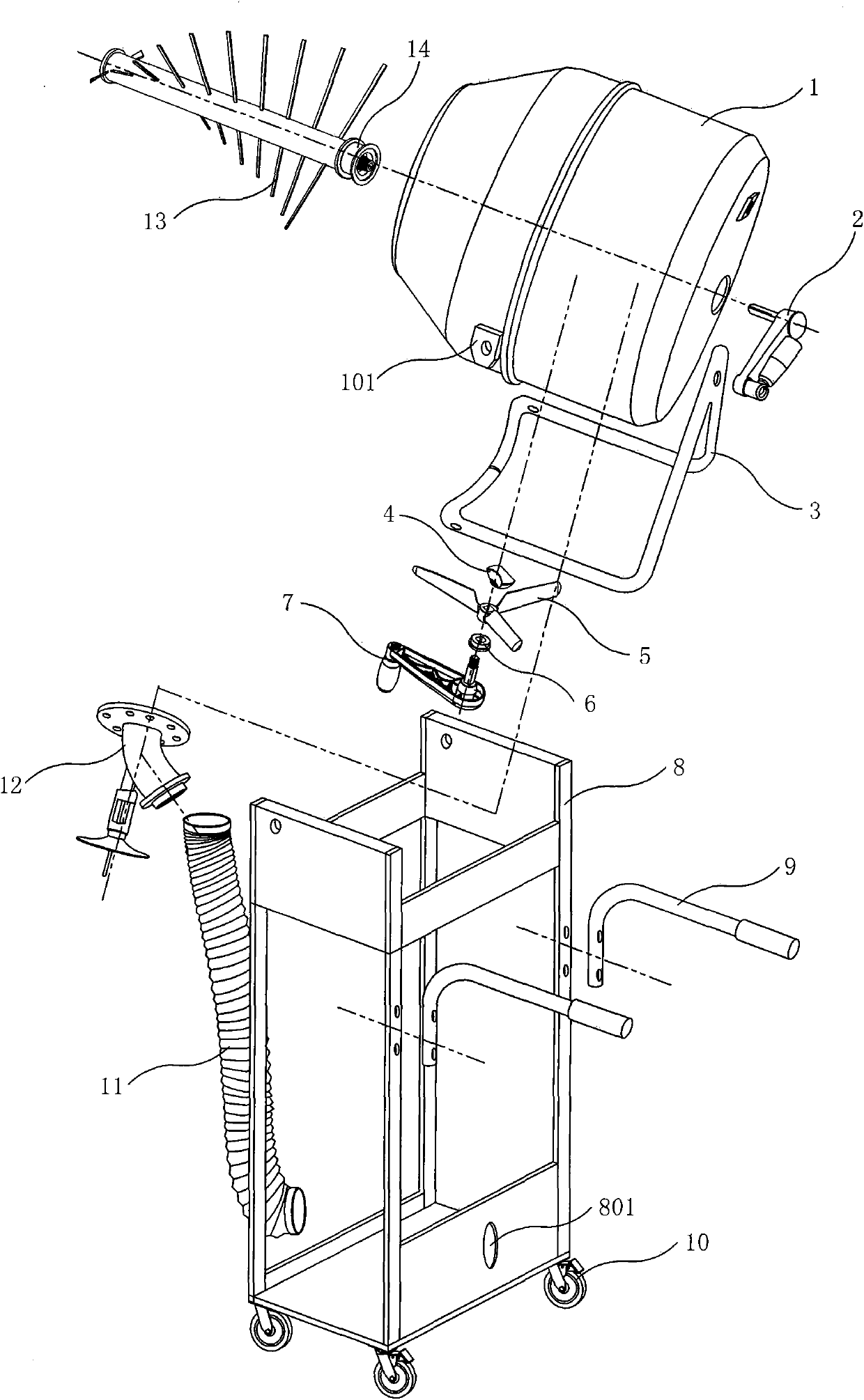

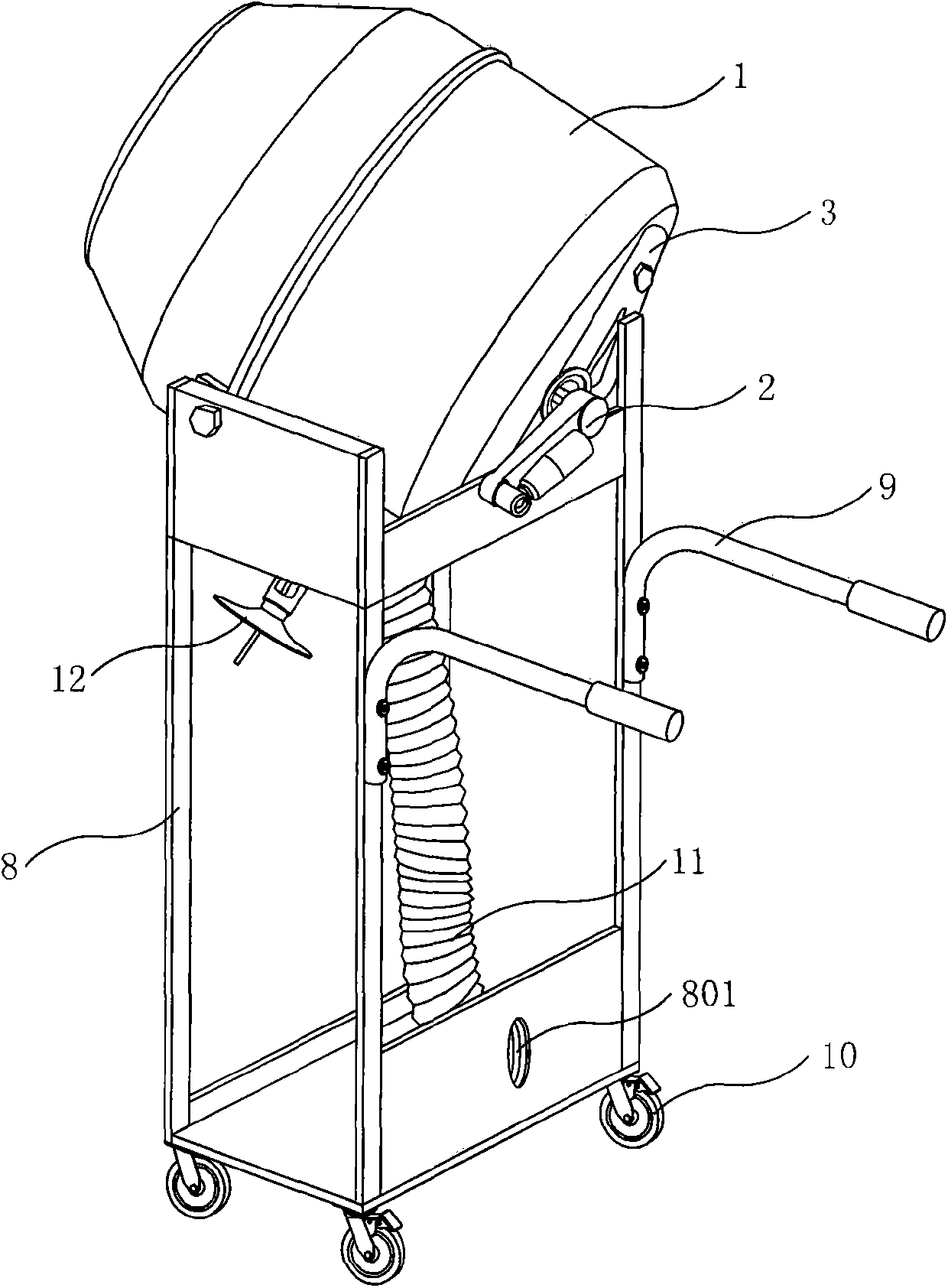

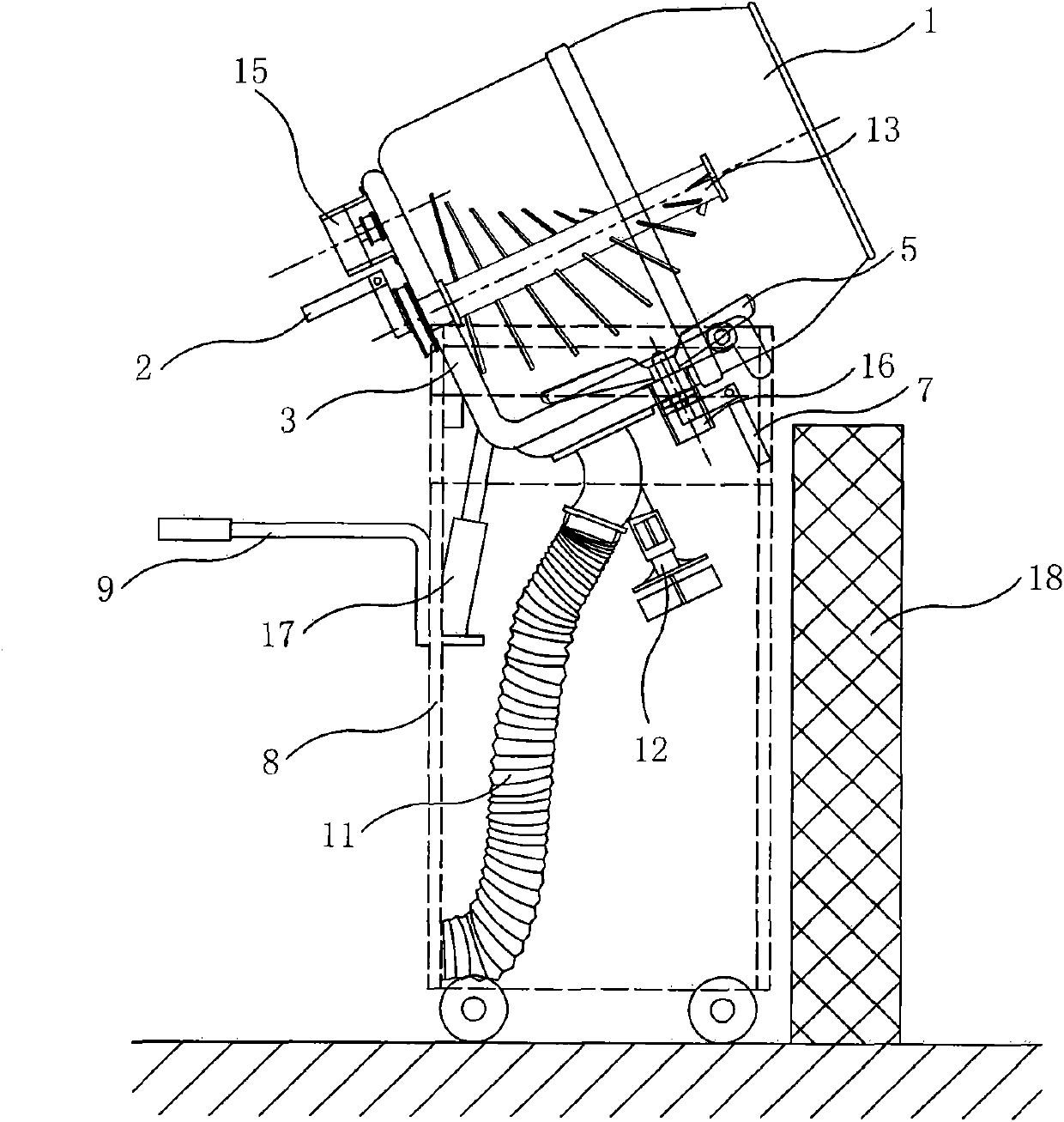

[0021] Now in conjunction with accompanying drawing, the present invention will be further described. Such as figure 1 , figure 2 As shown, the feed delivery trolley includes a material cylinder 1, a cylinder holder pipe rod 3, a stirring blade 5, a vehicle frame 8, and a screw rod 13. One side of the vehicle frame is provided with a push handle 9, and the material cylinder is from the mouth of the cylinder to the bottom of the cylinder. It is obliquely arranged on the baffle plate of the frame; that is, the bottom of the barrel is located on the push handle side of the frame, and a tube holder rod is arranged between the barrel and the frame, and the outer diameter of the barrel mouth side of the barrel is hinged through the ear 101 and the screw On the vehicle frame, the screw passes through the pipe rod of the cylinder holder, and the outer diameter of the bottom of the material cylinder leans against the vehicle frame. There is a discharge port at the bottom of the barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com