Method for performing biological denitrification of wastewater by using residual sludge and biological denitrification system for implementing same

A technology for excess sludge and biological denitrification, which is applied in the field of biological denitrification system, can solve the problems that the nitrogen index of the treated water cannot meet the standard, increase the operating cost of the sewage treatment plant, and reduce the denitrification effect of the system, so as to solve the problem of denitrification carbon source Insufficient, reduced processing costs, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

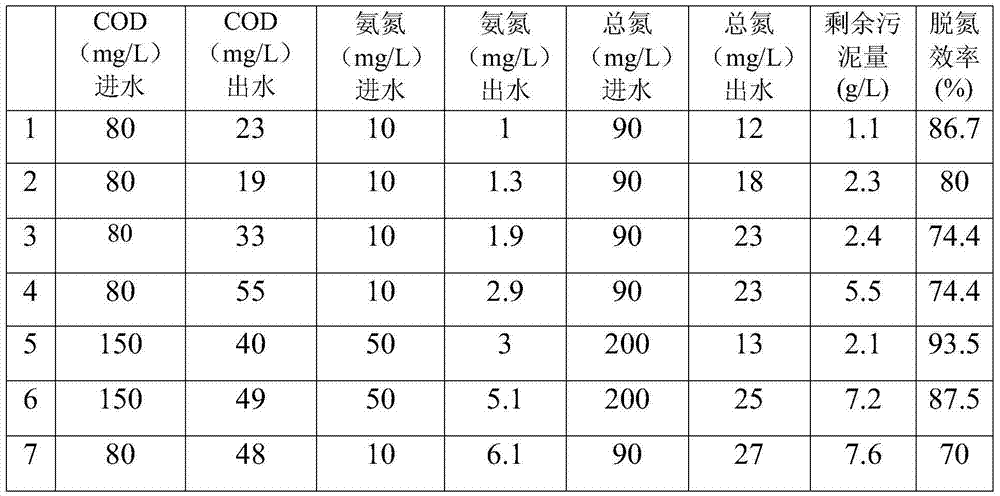

Embodiment 1

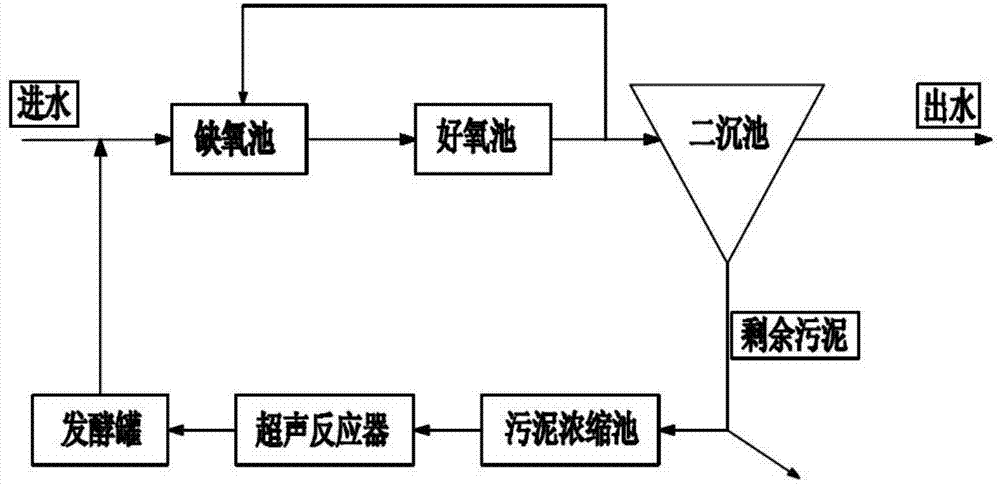

[0038] Such as figure 1 The wastewater biological denitrification system shown includes anoxic tank, aerobic tank and secondary sedimentation tank connected in sequence. The anoxic tank is equipped with a water inlet, and the anoxic tank is equipped with a stirring device; the bottom of the aerobic tank is equipped with perforated aeration. Hollow plastic balls are hung in the aerobic tank, and filter cloth is installed inside the ball; an internal backflow device is installed between the aerobic tank and the anoxic tank, and the secondary settling tank is equipped with a water outlet and a sludge discharge port. A water quality detector is installed between them; a sludge thickening tank, an ultrasonic processor and an anaerobic fermentation tank are sequentially connected between the sludge outlet and the water inlet.

[0039] In this embodiment, a method for biological denitrification of wastewater using excess sludge is to use figure 1 The implementation of wastewater bio...

Embodiment 2

[0047] In this embodiment, a method for biological denitrification of wastewater by using excess sludge is also used figure 1 The implementation of wastewater biological denitrification system includes the following steps:

[0048] (1) Take domestic sewage from the canal section of Hangzhou City (hereinafter referred to as canal sewage), and feed it into the anoxic pool, with 30L of water in each batch, and control the DO in the anoxic pool to 15mg / L, and the reaction time in the anoxic pool is 2h;

[0049] A hollow plastic ball with a diameter of 7cm is suspended in the aerobic pool, and a 40-mesh filter cloth with a proportion of 70% is installed in the ball. Water earthworms are mounted in the filter cloth, and the loading capacity of water earthworms is 2kg / L canal sewage; DO is 4~6mg / L, after 6 hours of reaction, return the nitrification solution to the anoxic tank, the reflux ratio of the nitrification solution (reflux flow / influent flow) is 100%, when the total nitrogen...

Embodiment 3

[0054] In this embodiment, a method for biological denitrification of wastewater by using excess sludge is also used figure 1 The implementation of wastewater biological denitrification system includes the following steps:

[0055] (1) Take the domestic sewage from the canal section of Hangzhou City (hereinafter referred to as the canal sewage), and feed it into the anoxic pool. Each batch of water intake is 30L. The DO in the anoxic pool is controlled at 0.4mg / L, and the reaction time in the anoxic pool is 2h;

[0056] A hollow plastic ball with a diameter of 7cm is hung in the aerobic pool, and a 40-mesh filter cloth with a proportion of 60% is installed in the ball. Water earthworms are mounted in the filter cloth, and the loading capacity of water earthworms is 2kg / L canal sewage; control the aerobic pool DO is 4~6mg / L, after 6 hours of reaction, return the nitrification solution to the anoxic tank, the reflux ratio of the nitrification solution (reflux flow / influent flow)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com