Treatment method of palmitic acid residues

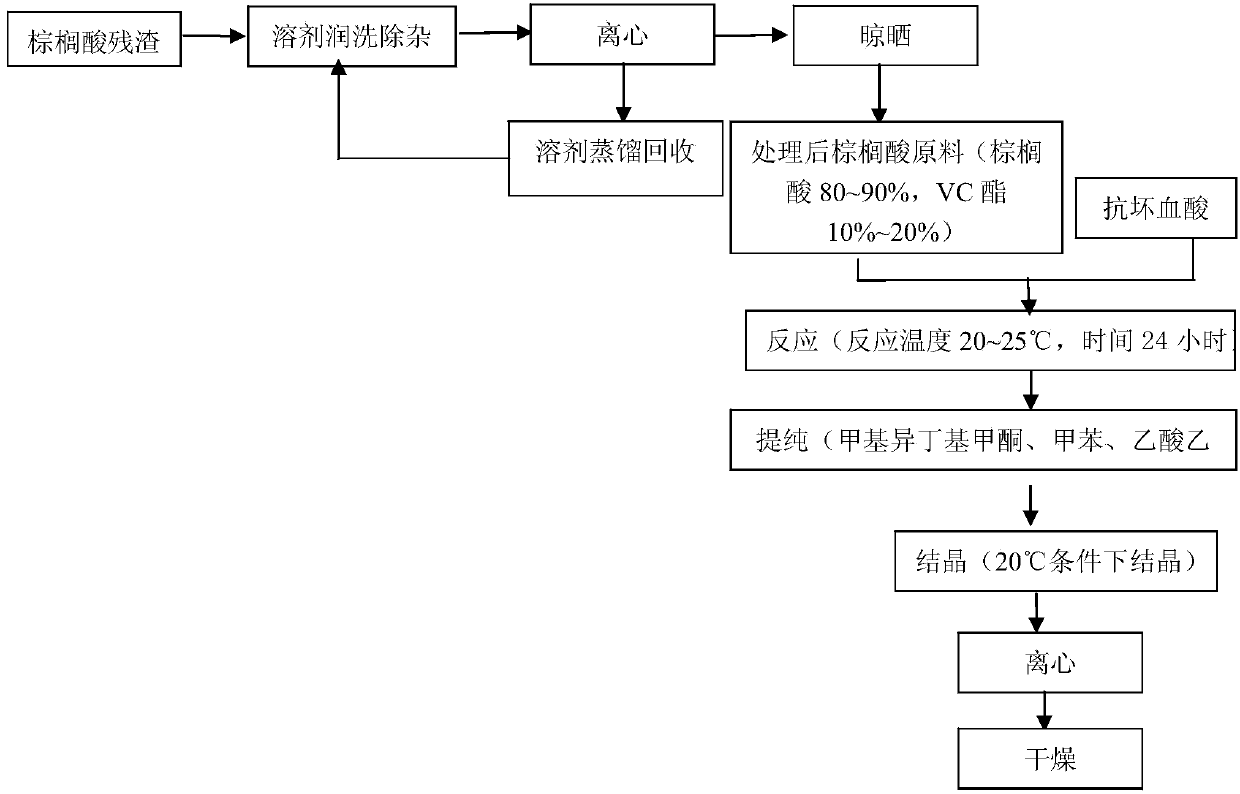

A treatment method and technology of palmitic acid, applied in organic chemistry and other directions, can solve the problems of unutilized waste residue, waste of raw materials, environmental pollution, etc., and achieve the effects of reducing pollution, improving product yield and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The treatment method of palmitic acid residue is firstly put the palmitic acid residue into the first reaction kettle, add ethyl acetate according to the mass ratio of palmitic acid residue:ethyl acetate at 1:10, and fully stir and mix to obtain the mixed slurry I. Then, the obtained mixed slurry I is centrifuged, and the obtained filter cake is air-dried to obtain the material II, and the obtained filtrate is distilled and returned to the first reaction kettle; the material II and ascorbic acid are put into the Fully react in the second reaction tank for 24 hours to obtain the reaction material III, and the reaction temperature is 25°C. Next, mix the reaction material III with ice at a mass ratio of 1:1.35, ice out, and precipitate VC palmitate, then add methyl isobutyl ketone and toluene for stripping for 35 minutes (the temperature is 60 °C ± 2, Stirring speed is 35 rev / min), until the material is completely dissolved, let it stand still, remove the acid liquid, crys...

Embodiment 2

[0030] The treatment method of the palmitic acid residue is firstly put the palmitic acid residue into the first reaction kettle, add ethyl acetate according to the mass ratio of palmitic acid residue:ethyl acetate as 1:7, and fully stir and mix to obtain the mixed slurry I. Then, the obtained mixed slurry I is centrifuged, and the obtained filter cake is air-dried to obtain the material II, and the obtained filtrate is distilled and returned to the first reaction kettle; the material II and ascorbic acid are put into the Fully react in the second reaction tank for 24 hours to obtain the reaction material III, and the reaction temperature is 22°C. Next, mix the reaction material III with ice at a mass ratio of 1:1.3, carry out ice crystallization, and precipitate VC palmitate, then add methyl isobutyl ketone and toluene for stripping for 30 minutes (the temperature is 60°C±2, Stirring speed is 30 rev / min), until the material is completely dissolved, let it stand still, remove ...

Embodiment 3

[0033] The treatment method of the palmitic acid residue is firstly put the palmitic acid residue into the first reaction kettle, add ethyl acetate according to the mass ratio of palmitic acid residue:ethyl acetate as 1:5, and fully stir and mix to obtain the mixed slurry I. Then, the obtained mixed slurry I is centrifuged, and the obtained filter cake is air-dried to obtain the material II, and the obtained filtrate is distilled and returned to the first reaction kettle; the material II and ascorbic acid are put into the Fully react in the second reaction tank for 24 hours to obtain the reaction material III, and the reaction temperature is 20°C. Next, mix the reaction material III with ice at a mass ratio of 1:1.25, carry out ice crystallization, and precipitate VC palmitate, then add methyl isobutyl ketone and toluene to dissolve and extract for 25 minutes (the temperature is 60 ° C ± 2, Stirring speed is 25 rev / min), until the substance is completely dissolved, let it stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com