High-rigidity low-warpage glass fiber reinforced polypropylene material

A polypropylene material, low warpage technology, applied in the field of polymer materials, can solve problems such as poor cold resistance, achieve the effect of reducing post-shrinkage and improving warpage deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

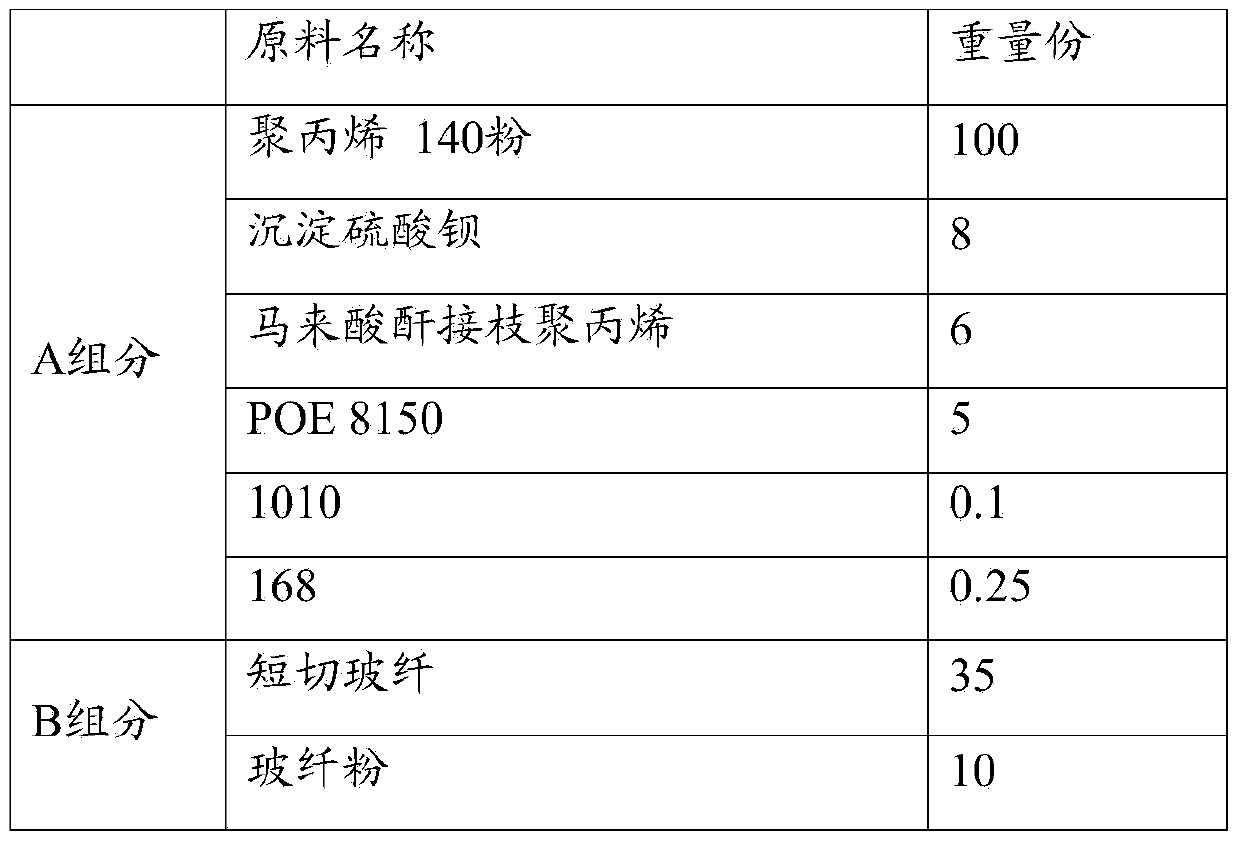

[0028] In parts by weight, the components of the raw materials of the high rigidity and low warpage glass fiber reinforced polypropylene material in this embodiment are shown in Table 1.

[0029] Table 1:

[0030]

[0031] .

[0032] The samples obtained in this embodiment were tested for notched Izod impact strength according to ASTM D256-2010, ASTM D790 for flexural modulus, and ASTM D638 for tensile strength. Inject the material described in the invention into a storage box with a length of 300mm, a width of 200mm, a height of 50mm, and a thickness of 4mm. After standing at room temperature for a week, visually inspect the warping and deformation of the lid / bottom junction. The test results are shown in Table 7.

Embodiment 2

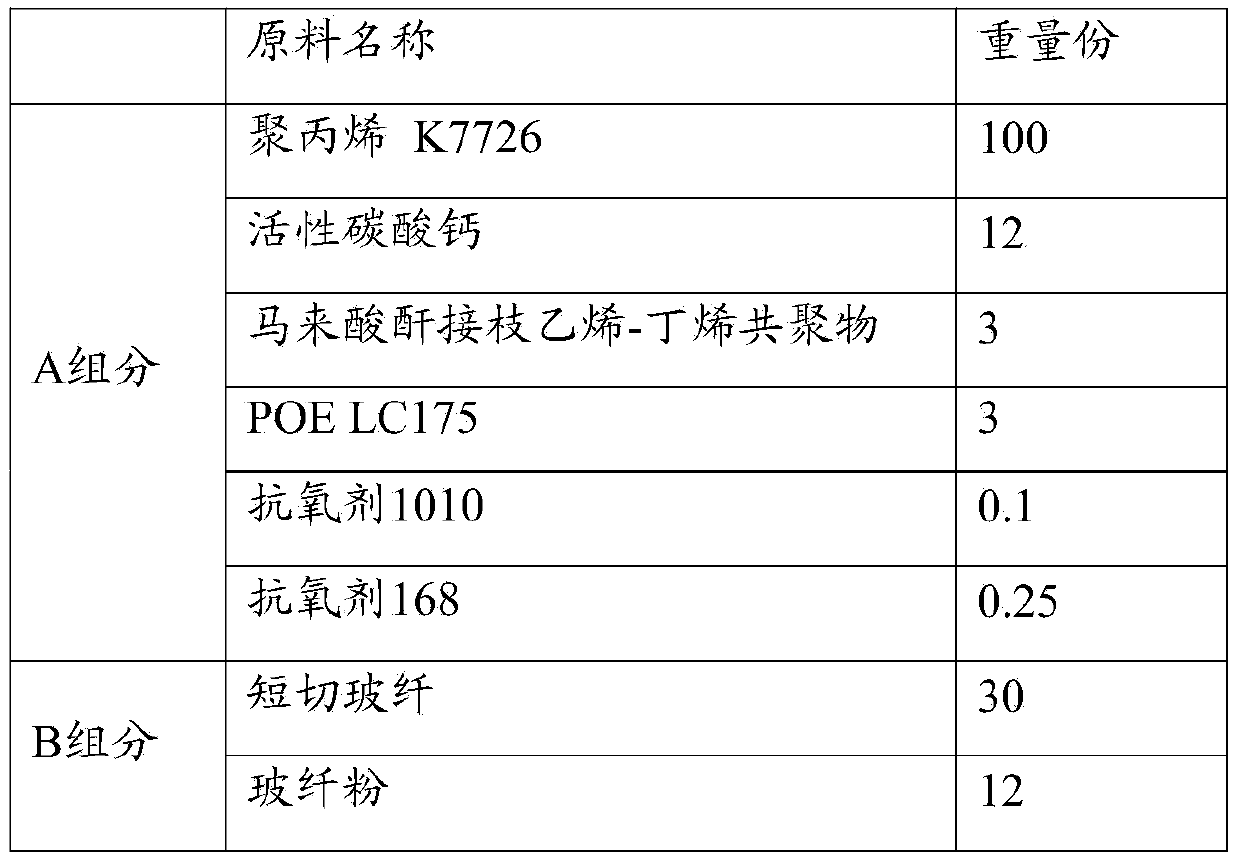

[0034] In parts by weight, the components of the raw materials of the high rigidity and low warpage glass fiber reinforced polypropylene material in this embodiment are shown in Table 2.

[0035] Table 2:

[0036]

[0037] .

[0038] The samples obtained in this embodiment were tested for notched Izod impact strength according to ASTM D256-2010, ASTM D790 for flexural modulus, and ASTM D638 for tensile strength. Inject the material described in the invention into a storage box with a length of 300mm, a width of 200mm, a height of 50mm, and a thickness of 4mm. After standing at room temperature for a week, visually inspect the warping and deformation of the lid / bottom junction. The test results are shown in Table 7.

Embodiment 3

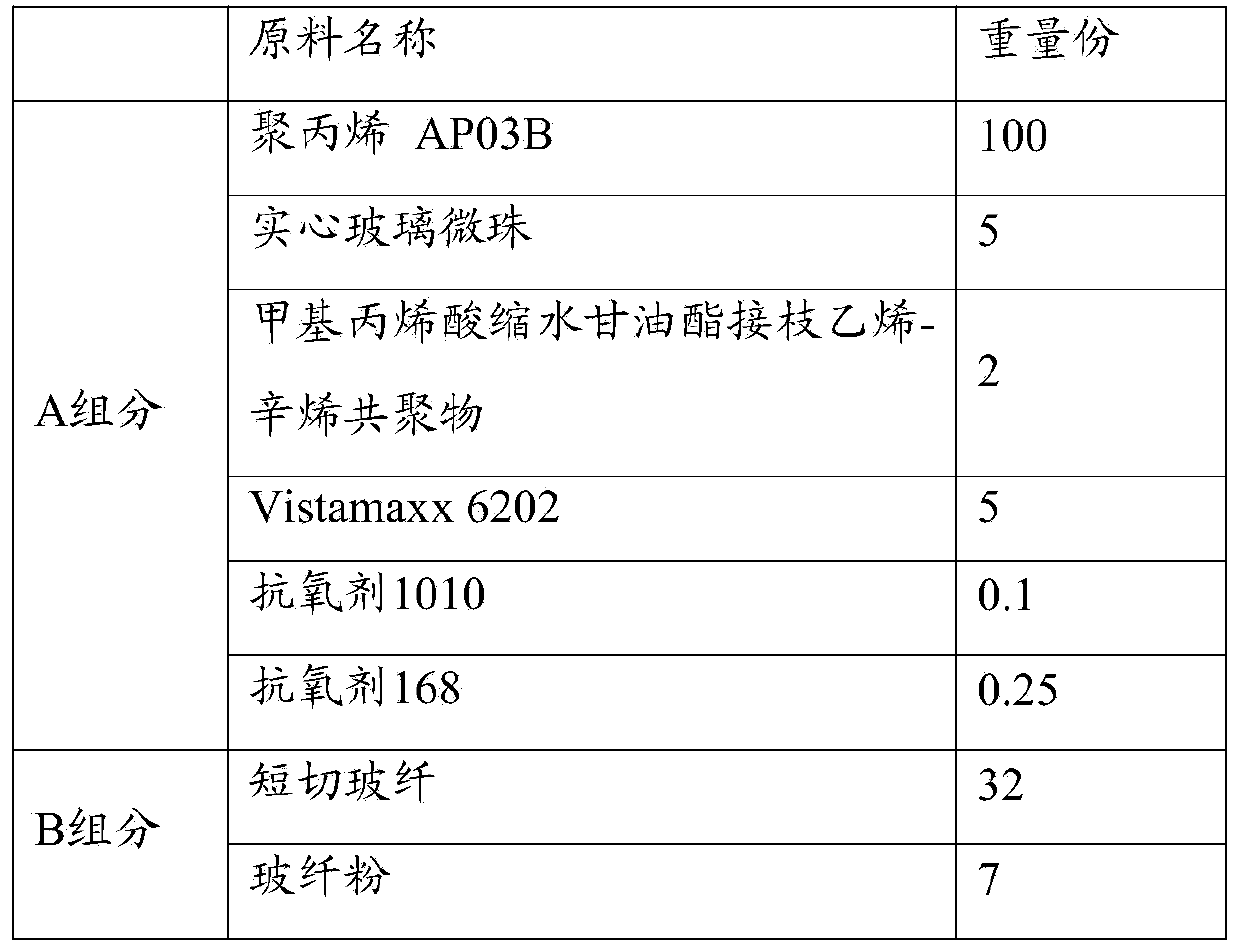

[0040] In parts by weight, the components of the raw materials of the high rigidity and low warpage glass fiber reinforced polypropylene material in this embodiment are shown in Table 3.

[0041] table 3:

[0042]

[0043] .

[0044] The samples obtained in this embodiment were tested for notched Izod impact strength according to ASTM D256-2010, ASTM D790 for flexural modulus, and ASTM D638 for tensile strength. Inject the material described in the invention into a storage box with a length of 300mm, a width of 200mm, a height of 50mm, and a thickness of 4mm. After standing at room temperature for a week, visually inspect the warping and deformation of the lid / bottom junction. The test results are shown in Table 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com