Carbon fiber reinforced resin composite material, use thereof and preparation method of rubber frame of electronic equipment enclosure and/or module

A technology of reinforced resin and composite materials, which is applied in the field of carbon fiber reinforced resin composite materials, can solve the problems that the rigidity and dimensional stability of glass fiber reinforced resin materials cannot meet the requirements of thin-walled products, and the appearance quality of parts is poor, so as to meet the requirements of high rigidity and high Dimensional stability, meeting toughness requirements, and improving strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

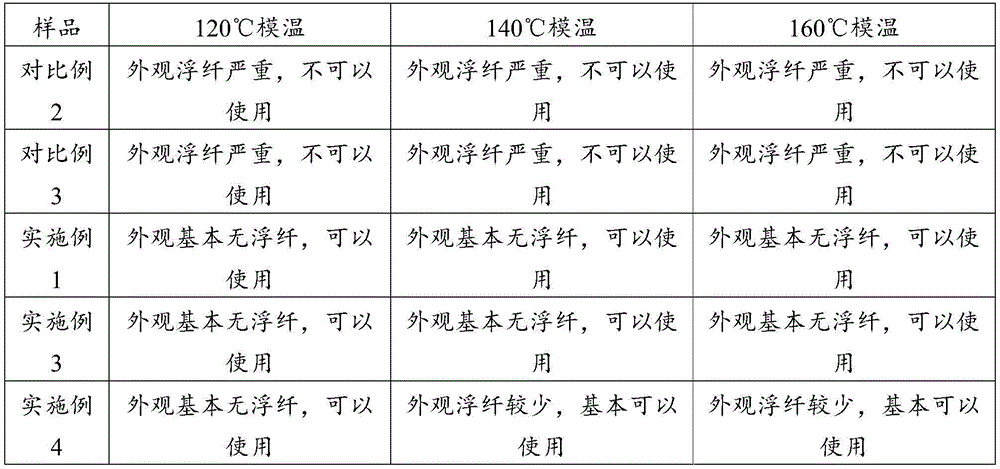

[0030] Correspondingly, an embodiment of the present invention also provides a method for preparing a plastic frame of an electronic device casing and / or module, which specifically includes:

[0031] Baking any carbon fiber reinforced resin composite material provided by the embodiments of the present invention at 80-90°C for 2-4 hours;

[0032]Plasticize and melt the carbon fiber reinforced resin composite material after baking; specifically, the process can be: add the carbon fiber reinforced resin composite material after baking into the hopper of the injection molding machine, and set the temperature of each section of the injection molding machine , so as to plasticize and melt the plastic;

[0033] The molten carbon fiber reinforced resin composite material is injected into a mold with a surface temperature of 100-170° C. to obtain a plastic frame of an electronic equipment case and / or module.

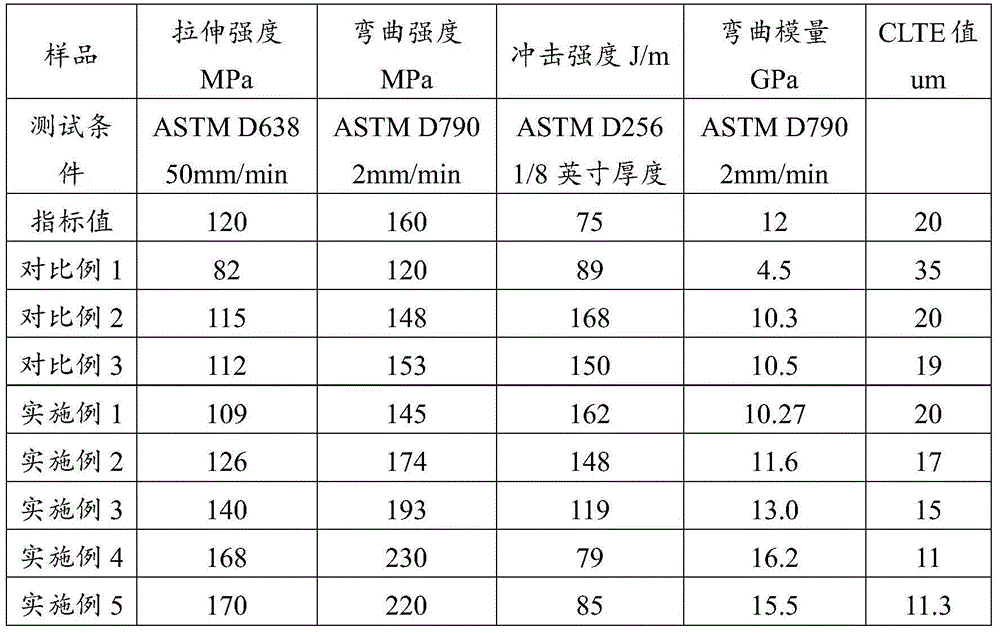

Embodiment 1

[0042] 15wt% carbon fiber, 69.9wt% 1017D type PC+ABS alloy, 12wt% lubricant PBT, 2wt% toughening agent 24MA005, 0.1wt% antioxidant 1076, 0.2wt% antioxidant 627, 0.5wt% lubricant PETS , 0.3wt% toner M900 are fully mixed, respectively put into a twin-screw extruder, extruded and granulated using the extruder at 230-250° C. to obtain a carbon fiber reinforced resin composite material, dried and packaged for use.

Embodiment 2

[0044] 18wt% carbon fiber, 63.8wt% 1017D type PC+ABS alloy, 14wt% lubricant PBT, 3wt% toughening agent 24MA005, 0.1wt% antioxidant 1076, 0.2wt% antioxidant 627, 0.6wt% lubricant PETS , 0.3wt% toner M900 are fully mixed, respectively put into a twin-screw extruder, extruded and granulated using the extruder at 230-250° C. to obtain a carbon fiber reinforced resin composite material, dried and packaged for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com