High temperature steam cooling system

A cooling system and high-temperature steam technology, applied in the field of heat exchange systems, can solve the problems of easy accumulation of impurities and scale, reduce the heat dissipation effect of the system, etc., and achieve the effects of high equipment use efficiency, prolonging cleaning cycle, and preventing liquid retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

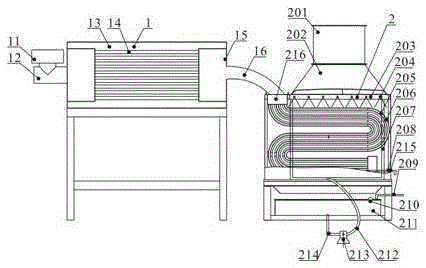

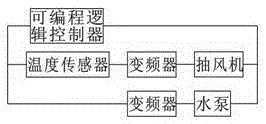

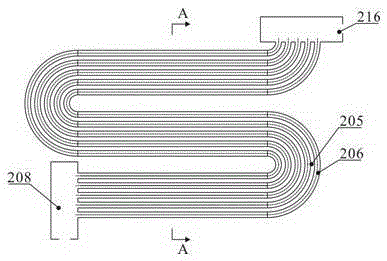

[0027] Such as figure 1 As shown, the cooling system includes a heat exchanger 1 and a steam cooler 2, and the heat exchanger 1 and the steam cooler 2 are connected by a steam pipe 16; the heat exchanger 1 includes a heat exchanger steam inlet 12, a water tank 13, and a condensation pipe 14 and the steam outlet 15 of the heat exchanger; the steam cooler 2 includes a "zigzag" cooling tube bundle 205 connected to the steam inlet 216, the cooling tube bundle 205 forms a certain angle with the horizontal direction, and the angle range is ±3o ~ 9o, the cooling tube bundle 205 A spray pipe 203 is provided above the spray pipe 203 , and a plurality of atomizing nozzles 204 facing the cooling tube bundle 205 are provided on the spray pipe 203 . The function of the heat exchanger 1 is to pre-cool the steam, and the absorbed heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com