Three-dimensional cell-mechanical-gradient loading platform

A gradient loading, three-dimensional cell technology, applied in tissue cell/virus culture devices, biochemical equipment and methods, stress-stimulated microbial growth methods, etc. , uneven extracellular matrix, etc., to achieve the effects of adjustable mechanical gradient, strong flexibility, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

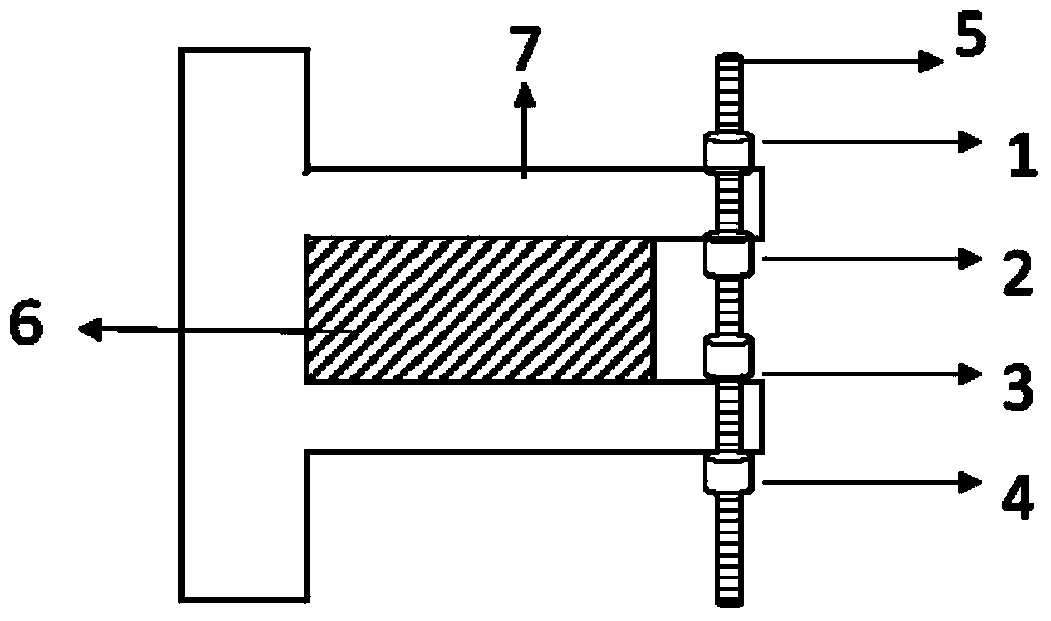

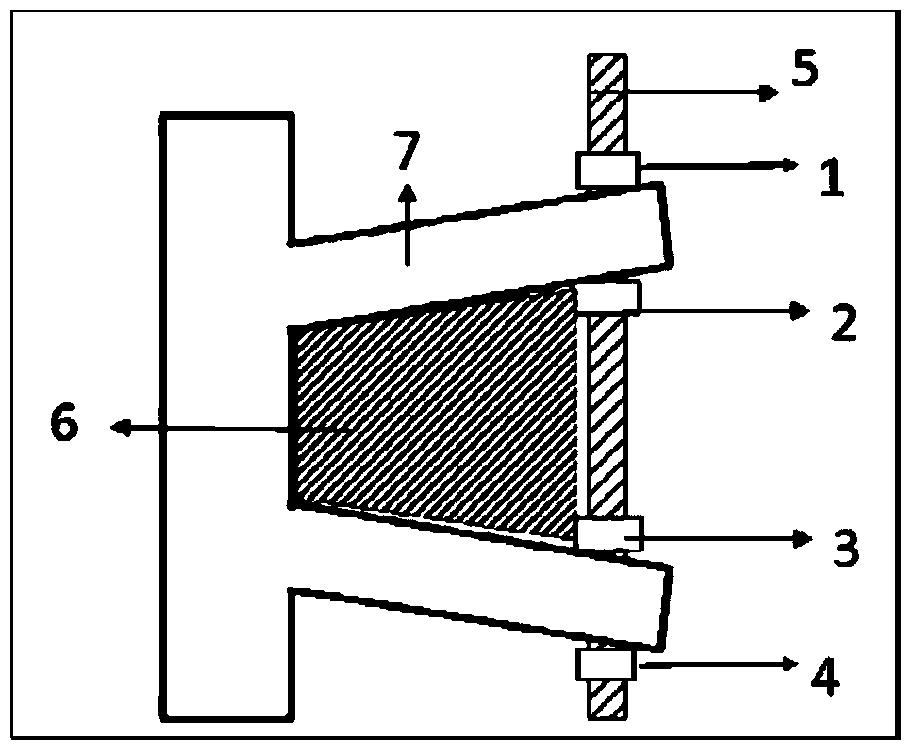

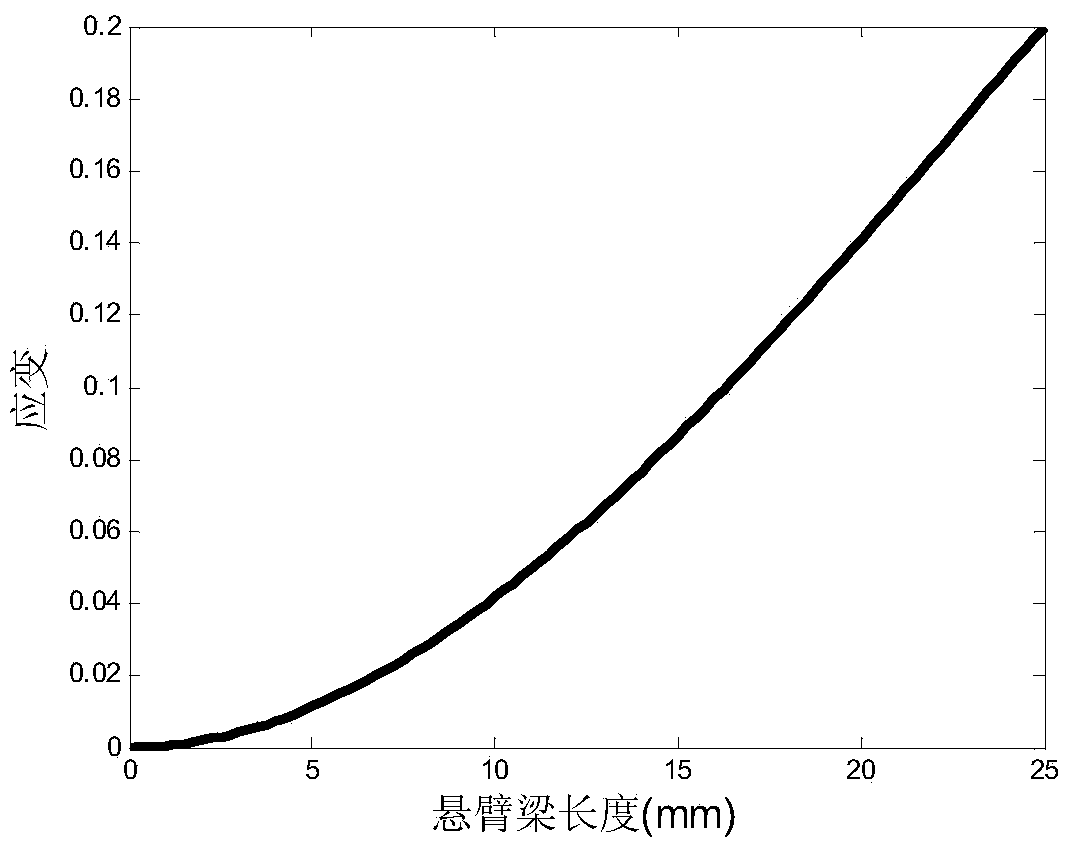

[0026] refer to figure 1 , using a computer to design two cantilever beams 7 in a rectangular shape (length 25mm, width 2.5mm, thickness 5mm), the distance between the two cantilever beams 7 is a three-dimensional cell gradient mechanical loading mold configuration, the mechanical loading device is made of organic material PMMA Cut to obtain a rectangular cantilever beam mold, and use a laser cutting machine to punch through holes consistent with the diameter of the threaded column at the ends of the two PMMA support cantilever beams 7, and the diameter of the threaded column 5 is 1.5mm. A three-dimensional tissue module 6 wrapped in cells is sandwiched between the two cantilever beams 7, and the contact parts of the three-dimensional tissue module 6 and the cantilever beams 7 are bonded with 502 glue. Hole, diameter 1.5mm, threaded column 5 passes through the through hole of two cantilever beams 7, the threaded column 5 on both sides of the through hole of one cantilever beam...

Embodiment 2

[0030] refer to Figure 4 , a three-dimensional cell mechanical gradient dynamic loading platform, including a mold composed of two cantilever beams 7, a three-dimensional tissue module 6 wrapped in cells is sandwiched between the two cantilever beams 7, and the contact position between the three-dimensional tissue module 6 and the cantilever beam 7 is used 502 glue connection, the ends of the two cantilever beams 7 are respectively connected to the control clips 8 provided on the one-dimensional mobile platform 9, and the two control clips 8 are respectively connected to the first motor 10 and the second motor 11. The computer can control the motor 10 and the motor 11 to move on a mobile platform, and the displacement is transmitted to the two cantilever beams 7 through the two control clamps 8 to generate a strain gradient.

Embodiment 3

[0032] refer to Figure 5, a high-throughput three-dimensional cell mechanical gradient static loading platform, a mold composed of two cantilever beam arrays with 7 arrays, a three-dimensional tissue module array wrapped in cells is sandwiched between the cantilever beam arrays, and the contact part between the three-dimensional tissue module array and the cantilever beam array Connected by 502 glue, the upper and lower ends of one cantilever beam array of the two cantilever beam arrays are respectively provided with a first plate 12 and the second plate 13, and the upper and lower ends of the other cantilever beam array are respectively provided with a third plate 14 and a fourth plate. Flat plate 15, a through hole is provided in the middle of the flat plate, a first nut 1 and a second nut 2 are provided on the threaded columns 5 on both sides of the through hole of the first flat plate 12 and the second flat plate 13 clamping a cantilever beam 7 array, A third nut 3 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com