Processing method for improving temper embrittlement resistance of steel plate for pressure vessels

A technology for pressure vessels and processing methods, which is applied in the processing field of improving the temper embrittlement resistance of steel plates for pressure vessels, can solve the problems of increased difficulty in smelting and high production costs, and achieve excellent temper embrittlement resistance of steel plates and low production costs. The effect of low cost and easy production organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The verification experiment was carried out through 14Cr1MoR (A387Gr11CL2) steel plate. The smelting composition of the steel plate: C: 0.13%, Si: 0.55, Mn: 0.50%, P: 0.013%, S: 0.001%, Cr: 1.25%, Mo: 0.46%, As: 0.003%, Sb: 0.001, Sn: 0.0019%, the balance is Fe, the J coefficient is 157, the X coefficient is 14.6, and the J coefficient exceeds 150 judgment value.

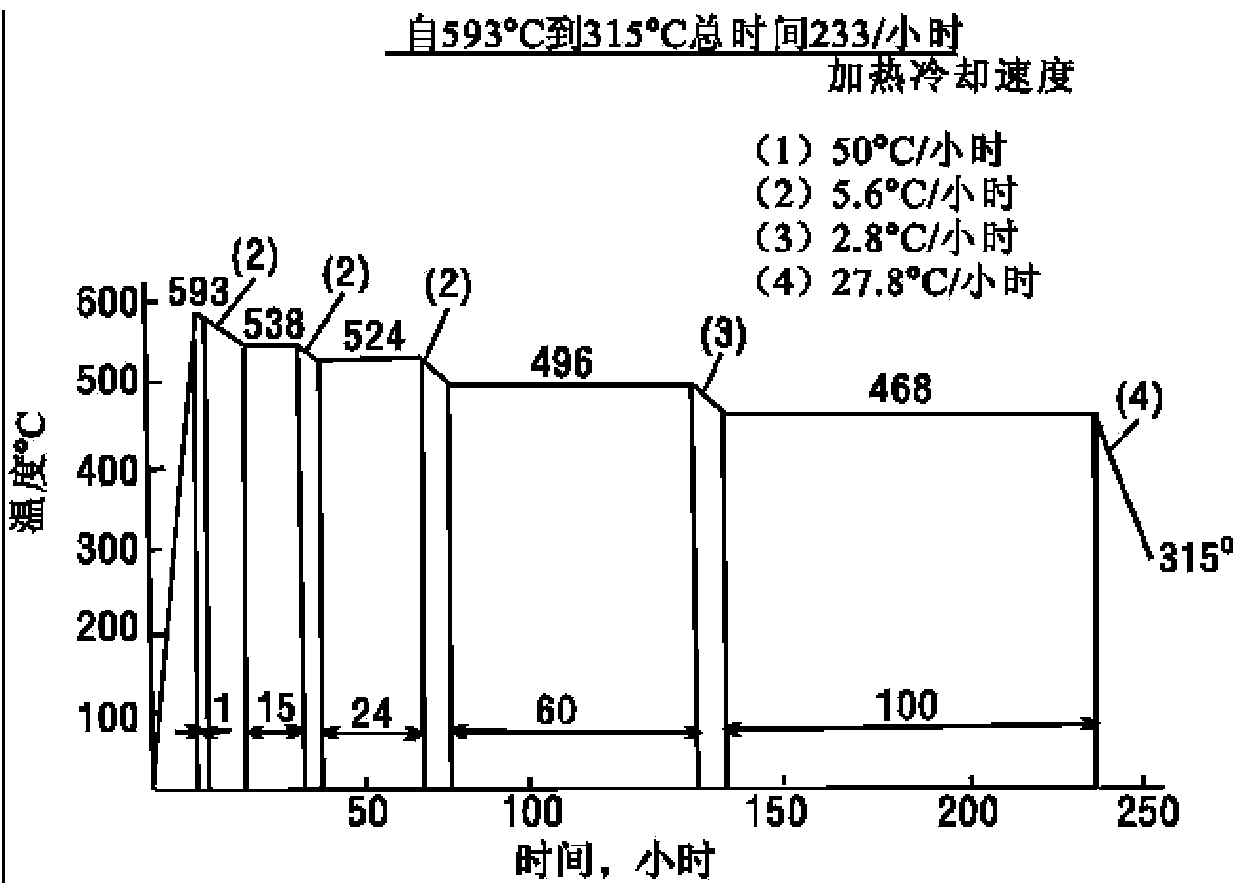

[0040] After the steel plate is kept at 920°C for 20 minutes, it is weakly water-cooled, the cooling rate is controlled at 3°C / s, and the final cooling temperature is 350°C; it is tempered at 710°C, and the tempering is kept for 15 minutes; after tempering, the steel plate is sampled and mined at 680°C. .PWHT treatment, the holding time is 8 hours; after that, the sample is subjected to a step-cooling experiment, and the heating curve is as attached figure 1 shown. After Min.PWHT treatment and step-cooling experiment, samples were taken respectively. Using the impact energy-temperature curve, it was detected...

Embodiment 2

[0042]The verification experiment was carried out through 12Cr2Mo1R (A387Gr22CL2) steel plate. The smelting composition of the steel plate: C: 0.11%, Si: 0.48, Mn: 0.55%, P: 0.011%, S: 0.002%, Cr: 2.24%, Mo: 1.00%, As: 0.002%, Sb: 0.002, Sn: 0.002%, the balance is Fe, the J coefficient is 134, the X coefficient is 13, and the J coefficient exceeds the judgment value of 100.

[0043] After the steel plate is kept at 920°C for 20 minutes, it is weakly water-cooled, the cooling rate is controlled at 4°C / s, and the final cooling temperature is 330°C; it is tempered at 730°C, and the tempering is kept for 15 minutes; after tempering, the steel plate is sampled and mined at 680°C .PWHT treatment, the holding time is 8 hours; after that, the sample is subjected to a step-cooling experiment, and the heating curve is as attached figure 1 shown. After Min.PWHT treatment and step-cooling experiment, samples were taken respectively. Using the impact energy-temperature curve, it was detec...

Embodiment 3

[0045] The verification experiment was carried out through 15CrMoR (A387Gr12CL2) steel plate. The smelting composition of the steel plate: C: 0.14%, Si: 0.44, Mn: 0.50%, P: 0.014%, S: 0.001%, Cr: 0.95%, Mo: 0.45%, As: 0.0015%, Sb: 0.003, Sn: 0.001%, the balance is Fe, the J coefficient is 141, the X coefficient is 16.1, and the X coefficient exceeds the judgment value.

[0046] After the steel plate is kept at 920°C for 20 minutes, it is weakly water-cooled, the cooling rate is controlled at 2°C / s, and the final cooling temperature is 300°C; it is tempered at 710°C, and the tempering is kept for 15 minutes; after tempering, the steel plate is sampled and mined at 680°C. .PWHT treatment, the holding time is 8 hours; after that, the sample is subjected to a step-cooling experiment, and the heating curve is as attached figure 1 shown. After Min.PWHT treatment and step-cooling experiment, samples were taken respectively. Using the impact energy-temperature curve, it was detected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com