Special process for freely forging EH36 optimized material steel ingot into plate-shaped bearing seat forged piece

An EH36, bearing seat technology, applied in the field of plate bearing seat forgings, can solve problems such as failure to meet product design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

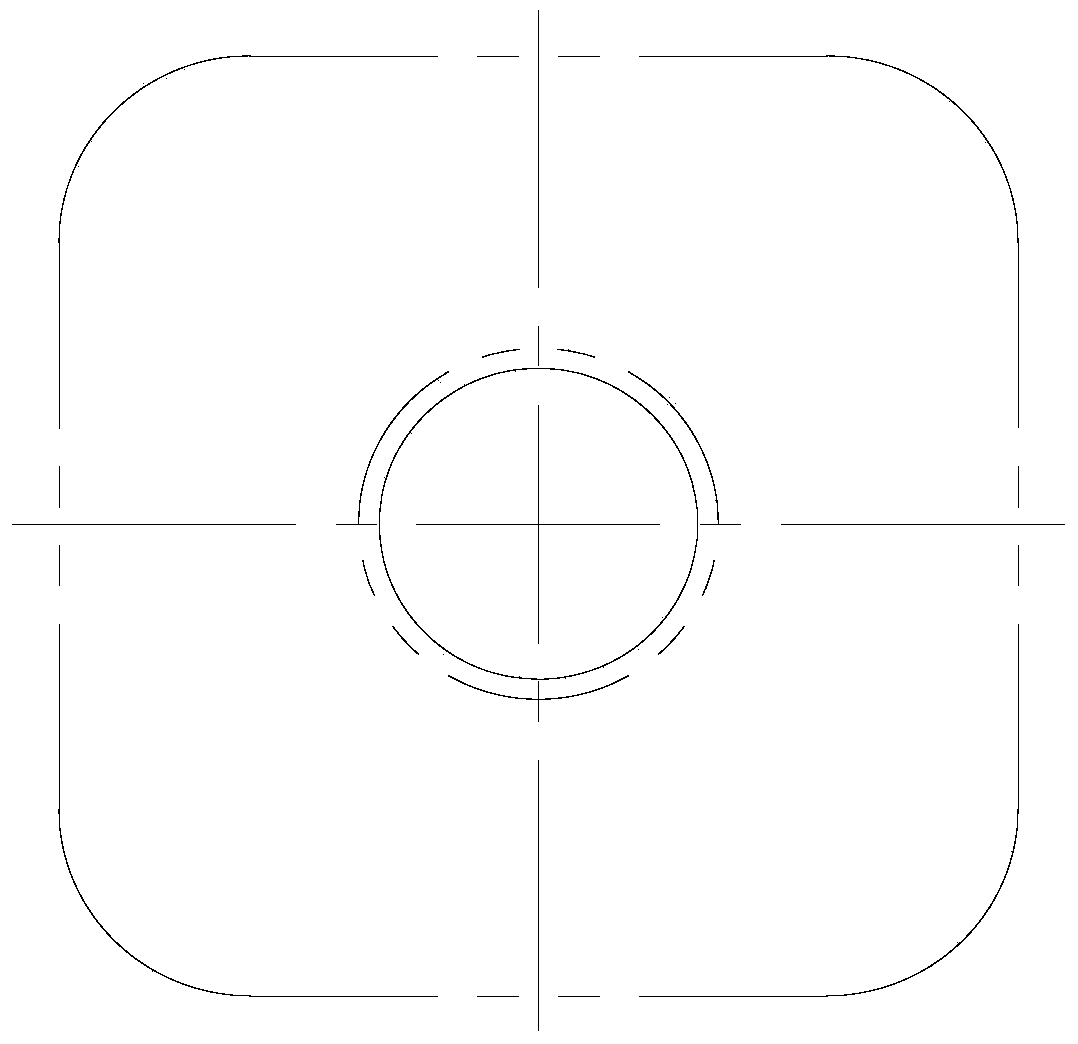

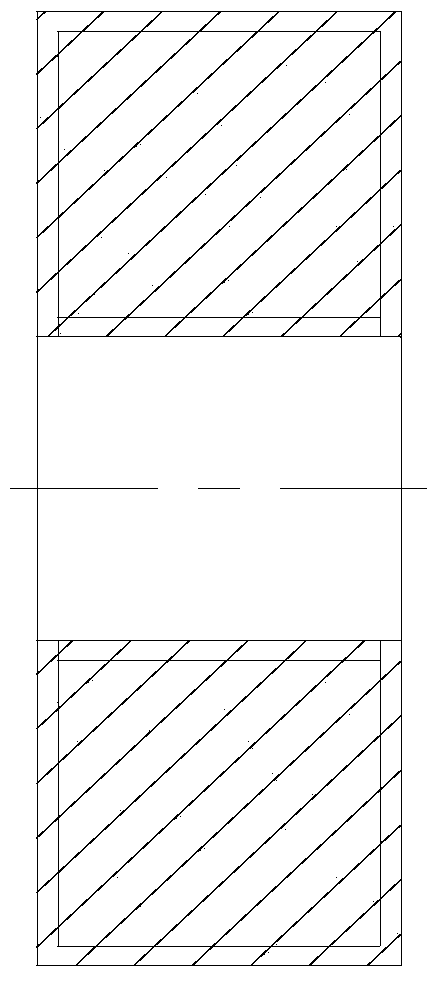

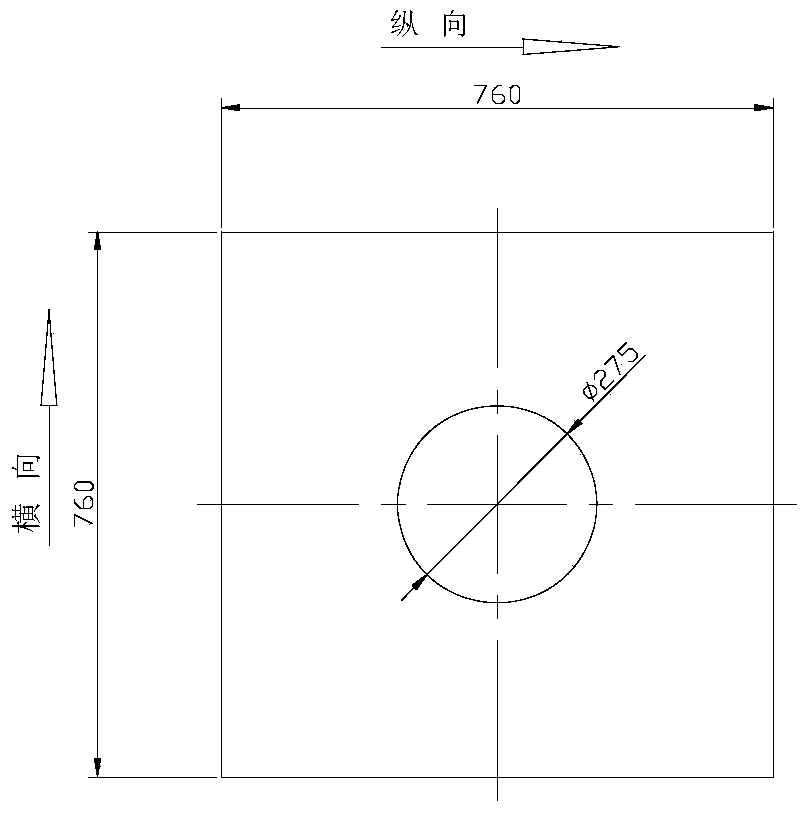

[0034] Embodiment 1: with reference to accompanying drawing 1. A special process for free forging EH36 steel ingots into plate-shaped bearing seat forgings. On the premise of obtaining qualified raw materials, the process specification must include the following:

[0035] 1. Heating specifications - furnace loading temperature, heating speed and holding time, and furnace temperature.

[0036] Steel ingot with 17〞square section is used, the furnace temperature is not higher than 350±10℃, and the temperature rises with the furnace. During the heating process, when the furnace temperature rises to 900±10℃, keep it warm for 2 hours, and then heat it to the initial forging temperature of 1200±10℃ Heat at 10°C for 1 hour and take out.

[0037] 2. Deformation process—including forging equipment, deformation process, material deformation degree and forging ratio, steel ingot upsetting, punching and leveling, correction until the forging is completed, removal of steel ingot bottom and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com