Colorful spunlace nonwoven fabric fadeless when being wetted and manufacturing method

A non-woven fabric and non-woven technology, applied in the direction of non-woven fabrics, textiles and papermaking, can solve the problems of low transverse strength, inability to realize colorful non-woven fabric manufacturing, environmental pollution, etc., and achieve a simple and easy production method, realize The effect of zero-cost production promotion and less allergic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

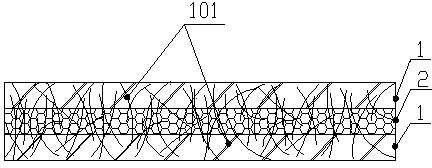

[0015] Embodiment 1: with reference to attached figure 1 and 2 . A colorful non-fading spunlace nonwoven fabric when wet, the colored PP spunlace nonwoven fabric 2 is intertwined with the fibers 101 in the spunlace nonwoven fabric 1 covering the upper and lower layers to form a colored spunlace nonwoven fabric and The color spunlace nonwoven fabric surface shows the color PP color. Colored PP spunlace nonwoven fabric 2 is colored PP spunbonded nonwoven material. Colored PP spunlace nonwoven fabric 2 can be colored monochrome, or multi-colored.

Embodiment 2

[0016] Example 2: On the basis of Example 1, the colored spunlace nonwoven fabric surface exhibits colored PP colors and spunlace nonwoven fabric fibers are mixed in the colored PP colors.

Embodiment 3

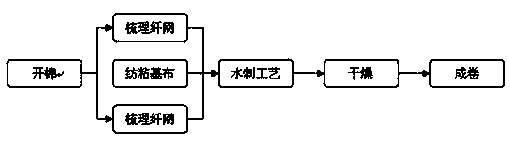

[0017] Example 3: On the basis of Example 1, a method for making a colorful non-fading spunlaced nonwoven fabric when wet, the first step is to open the two fiber raw materials separately, and the fibers after opening are fluffy and mixed Finally, carding and fiber interlacing are carried out on the machine to form the upper spunlace nonwoven fiber preparation layer and the lower spunlace nonwoven fiber preparation layer; the second step is carried out simultaneously with the first step, and the colored PP spunbond base fabric is unrolled Involved in the machine; the third step is to superimpose the upper layer of spunlace nonwoven fiber preparation layer, the middle layer of colored PP spunbond base fabric, and the lower layer of spunlace nonwoven fiber preparation layer together and then enter the machine for spunlace, and the spunlace after spunlace The non-woven surface fiber shows the color of colored PP; the fourth step, the spunlace colored non-woven fabric is dried in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com