Angle adjusting mechanism for multifunctional drilling machine

An angle-adjusting, multi-functional technology, applied in drilling equipment, directional drilling, earth-moving drilling, etc., can solve the problems of unreasonable construction technology, endangering own safety, high technical complexity, and shortening and saving time for repair and maintenance. Expenses, technical design simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

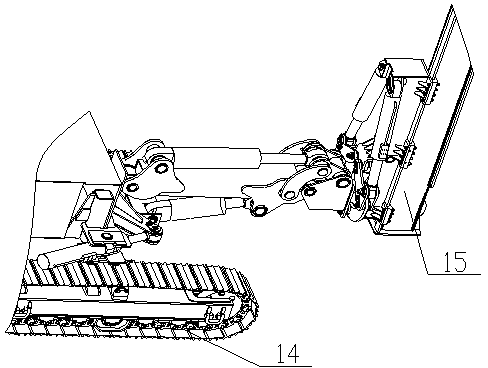

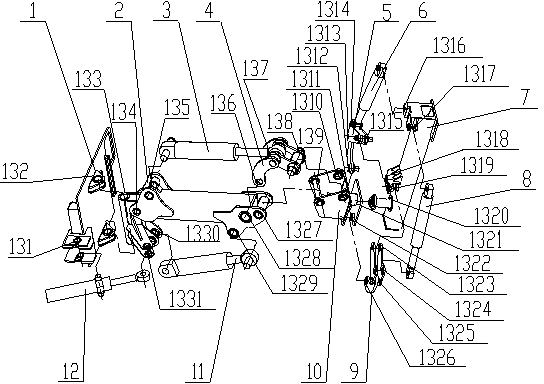

[0016] Such as figure 1 with figure 2 As shown, the angle adjustment mechanism of this multifunctional drilling rig includes a fixed seat 1, a main connecting frame 2, a forward oil cylinder 3, a free connecting frame 1, a free connecting frame 2 5, a left adjusting oil cylinder 6, a sliding frame 7, and a right adjusting Oil cylinder 8, free connecting frame 3 9, rotating connecting seat 10, luffing oil cylinder 11, rotating oil cylinder 12, hinge point 1 131, hinge point 2 132, hinge point 3 133, hinge point 4 134, hinge point 5 135, hinge point Six 136, hinge point seven 137, hinge point eight 138, hinge point nine 139, hinge point ten 1310, hinge point eleven 1311, hinge point twelve 1312, hinge point thirteen 1313, hinge point fourteen 1314, hinge point ten Five 1315, hinge point 16 1316, hinge point 17 1317, hinge point 18 1318, hinge point 19 1319, hinge poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com