Composite grate device

A technology of grate and fixed grate, which is applied to incinerators, combustion methods, combustion types, etc., can solve the problems of inability to realize composite adjustment of the structure of grate pieces, and reduce the difficulty of assembly, reduce labor intensity, and improve assembly efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

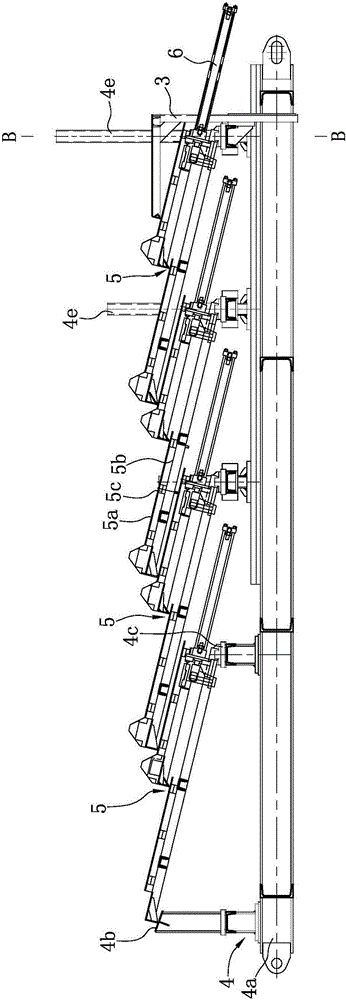

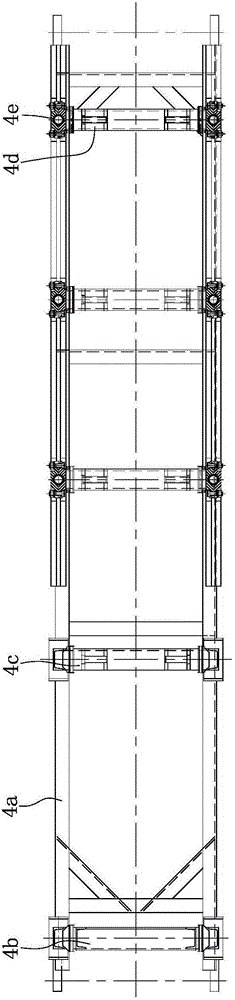

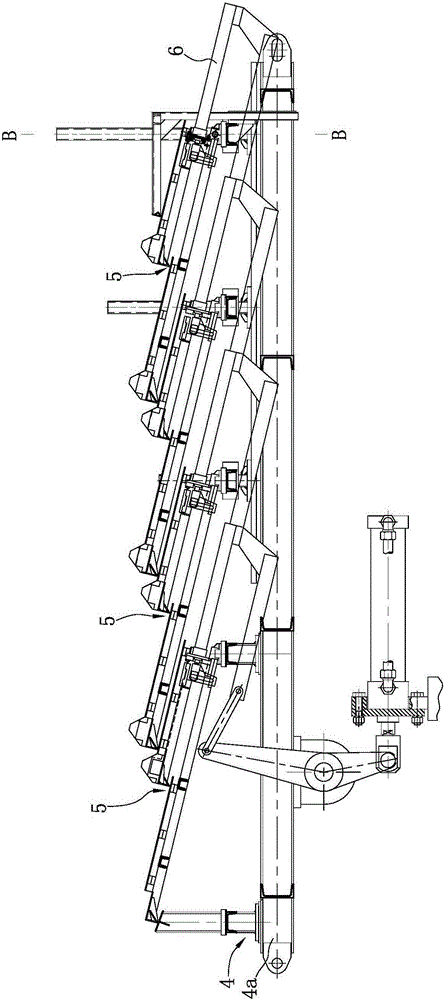

[0023] Such as figure 1 , figure 2 , image 3 As shown, the grate support frame 4 has two left and right longitudinal beams 4a arranged parallel to each other and symmetrically arranged, and the two longitudinal beams 4a are fixed by a plurality of connecting beams arranged sequentially from front to back. A standard fire grate module is installed on the fire grate support frame 4, and the standard fire grate module is composed of multi-level standard fire grate modules 5 arranged sequentially from front to back, and each standard fire grate module 5 is set with a high front and a low slope at the rear. The number of standard fire grate modules 5 is determined according to actual needs, and the present embodiment is preferably four. Each standard fire grate module 5 is composed of a fixed fire grate and a movable fire grate, and the fixed fire grate and the movable fire grate of each standard fire grate module 5 are composed of a base body 5a and a back plate 5b, and the ba...

Embodiment 2

[0030] refer to image 3 , In this embodiment, the driving device 6 is a driving rod, and correspondingly, the positioning seat is a guiding seat. The driving rod is installed on the guide seat, the front end of the driving rod is connected with the driving support, and the driving rods of the multi-stage standard fire grate module 5 are connected into one, jointly driving the movable fire grate to reciprocate. The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com