An energy-saving frame kiln furniture for firing high-voltage electric porcelain products

A high-voltage electric porcelain and frame technology, applied in the field of kiln furniture, can solve the problems of low loading density, high labor intensity, volume expansion, etc., and achieve the effects of improving product grade, reducing labor intensity, and small heat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

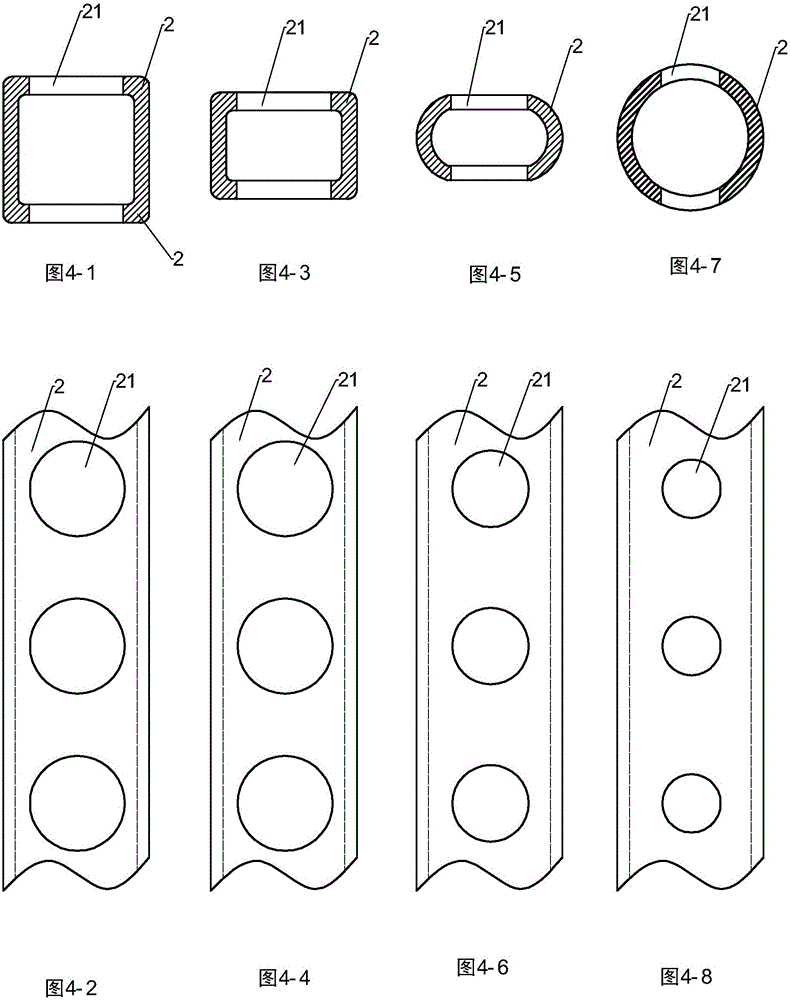

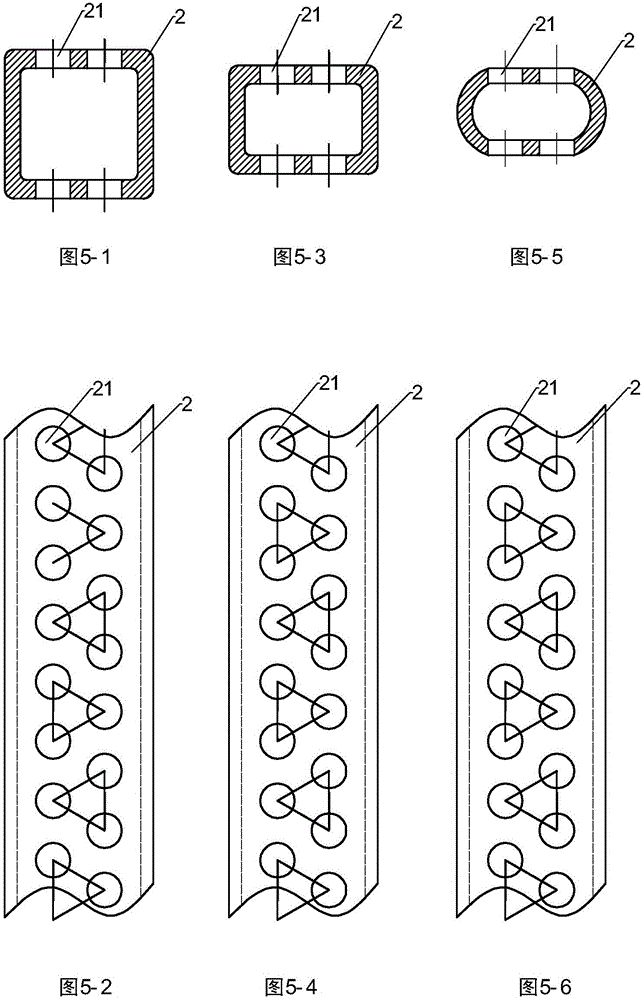

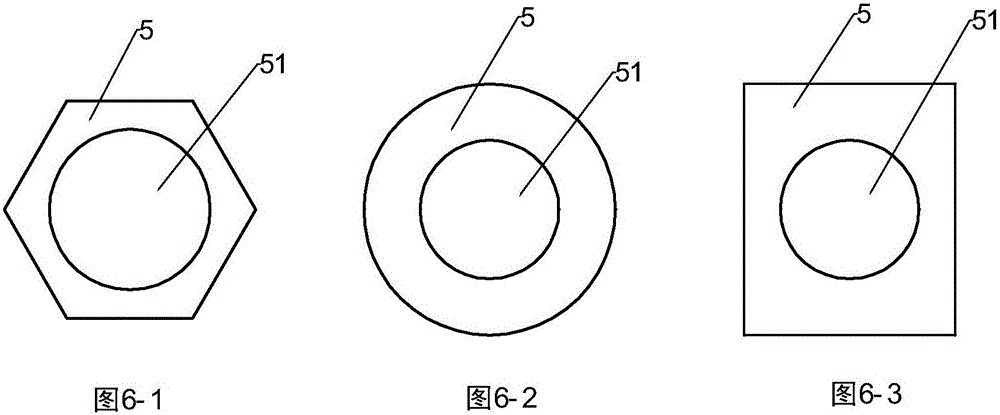

[0027] Embodiment 1, with reference to Figure 1-Figure 9 , an energy-saving frame kiln furniture for firing high-voltage electric porcelain products, comprising a trolley 1, a column 2, a main beam 3 and an auxiliary beam 4, six columns 2 are arranged on the trolley 1, and each column 2 is provided with The shelf through hole 21 is provided with a shelf main beam 3 in the width direction of the trolley 1, and each main beam 3 is horizontally erected on the shelf through hole 21 of the two front and rear columns 2; in the length direction of the trolley 1 There are 6 sets of auxiliary beams 4 on each upper floor, and the auxiliary beams 4 are erected on the two adjacent main beams 3 on the left and right, and are set at 90° to the main beams 3. There are two sets of auxiliary beams 4 in each group. On the crossbeam 4, the tile frame is provided with 8 supporting plates 5, and each supporting plate 5 is equipped with a bowl support 6, and the middle of each supporting plate 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com